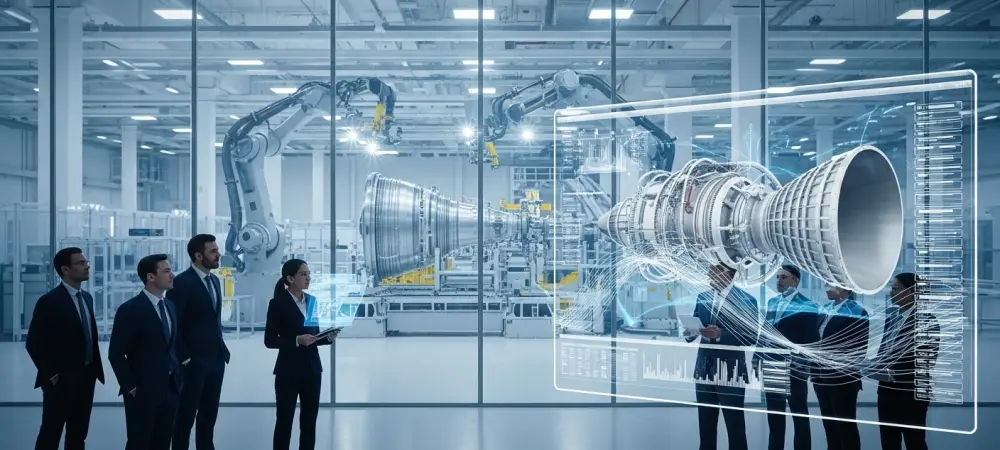

A pivotal shift is underway within the landscape of industrial automation, where the recent integration of xAI’s artificial intelligence capabilities into SpaceX’s core manufacturing operations marks more than a simple technology acquisition. This strategic move is a seminal event, poised to act as a powerful “forcing function” that will fundamentally accelerate the evolution of automated production toward a future of genuine, large-scale autonomous manufacturing. By leveraging the uniquely demanding environment of aerospace production as a crucible for innovation, SpaceX is set to pioneer new standards, frameworks, and technologies that will inevitably cascade across all high-precision industries. The central theme emerging from this development is the transition of AI from a peripheral analytical tool to the central nervous system of automated production. This transformation is not merely about adding intelligence to existing systems but about rebuilding the very foundation of manufacturing around AI-driven learning, adaptation, and control. The immense scale, speed, and complexity inherent in rocket and satellite production create an environment where traditional methods of manual optimization and reliance on disconnected data systems are no longer viable, making advanced AI an absolute operational necessity.

A New Blueprint for Manufacturing

The “Forcing Function” of Aerospace Production

The concept of a “forcing function” is critical to understanding the profound implications of this integration. Unlike many companies where AI is adopted as an experimental side project or a supplementary analytics tool, the operational demands at SpaceX make advanced artificial intelligence an indispensable component of its production infrastructure. The sheer volume of components, the extreme tolerances required, and the unforgiving nature of space exploration mean that relying on slow, periodic process re-engineering and manual oversight is simply not an option. This necessity is pulling AI directly into the heart of automated production, compelling a fundamental shift from adding AI to existing automated manufacturing to rebuilding automated manufacturing around AI-driven intelligence. This is a crucial distinction, as it moves the industry beyond incremental improvements and toward a complete paradigm shift. The goal is to create a system capable of understanding the intricate interplay of countless variables in real time, proactively detecting potential issues before they escalate into costly failures, and fostering a culture of continuous, automated improvement rather than relying on infrequent, disruptive overhauls.

This high-stakes environment serves as the ultimate proving ground for autonomous systems. The challenges inherent in aerospace production—complex assemblies, zero margin for error, and the need for absolute reliability—force the development of AI systems that are not just intelligent but also robust, transparent, and trustworthy. By tackling these challenges head-on within one of the world’s most demanding manufacturing contexts, SpaceX and xAI are effectively creating a comprehensive blueprint for the future of industrial automation. The solutions developed to manage the complexities of rocket manufacturing will be directly applicable to other sectors where precision, quality, and efficiency are paramount. This initiative will therefore not only advance SpaceX’s capabilities but also establish new industry norms built around AI-enabled, software-defined automation, significantly shortening the timeline for the widespread adoption of these advanced technologies across the global manufacturing landscape. The resulting architectures, compliance frameworks, and practical applications for closed-loop autonomy will have a far-reaching impact, setting a new standard for what is possible in modern production.

Shifting from Static Recipes to Dynamic Adaptation

A major transformation spurred by this integration involves the evolution of high-precision manufacturing from a rigid, predetermined methodology to a dynamic, intelligent, and continuously learning process. For decades, the prevailing industrial paradigm has been built upon manually engineered, static “recipes.” This traditional approach involves setting fixed parameters for machines, implementing controls designed to minimize any variation from those parameters, and conducting quality inspections at the end of the production line to catch defects. While this method has proven effective in stable, predictable conditions, it is inherently slow to adapt to change. It is vulnerable to environmental shifts or material drift and can be exceedingly expensive to re-validate, particularly when production requirements are in constant flux. In this model, the factory operates on a set of hard-coded assumptions about a perfect, unchanging environment, a scenario that rarely reflects the complex realities of the factory floor. Any deviation from the established norm often results in scrap, rework, and costly downtime, hindering agility and innovation. In stark contrast, the AI-driven adaptive model envisions manufacturing as a system that behaves more like a biological organism, capable of constantly sensing its environment and adjusting its behavior in response. With AI deeply embedded into production systems, robotic applications will intelligently modify their processing based on live sensor feedback, moving far beyond the limitations of rigid, pre-programmed paths. Instead of automatically rejecting a part due to minor material or environmental variations, the system will learn to adjust its workflow on the fly to compensate, a capability that will significantly reduce waste and improve overall yield. This new paradigm extends to quality assurance, shifting it from a post-production inspection activity to a predictive process that occurs during manufacturing, allowing for immediate corrective action. Critical process windows, once permanently locked down, can be optimized in real time to maximize both efficiency and resilience. This approach does not seek to replace deterministic control but rather to layer a sophisticated level of intelligence on top of it, allowing software-defined automation to respond dynamically and intelligently to the real world.

Building the Intelligent Factory

The Unparalleled Advantage of Unified Data

The true, game-changing power of the SpaceX-xAI combination lies not merely in the development of superior AI models but in the unparalleled scale and richness of the data that will fuel them. SpaceX’s vertically integrated production environment is a data-generation powerhouse, creating exhaustive, high-quality industrial data sets that are typically fragmented and inaccessible in most factory settings. This comprehensive data stream includes high-frequency telemetry from machines and robots, extensive vision and imaging data from inspection and assembly processes, detailed process parameters from every stage of production, continuous environmental condition monitoring, and exhaustive quality results, including rework records. Furthermore, this data is connected to the extensive test, validation, and operational performance data gathered from the finished products themselves, creating a complete, end-to-end view of the manufacturing lifecycle. This stands in stark contrast to the common industrial landscape, where critical information is often siloed across disparate, non-communicating systems.

In a typical factory, the robot controller has its logs, the Programmable Logic Controller (PLC) has its tags, the quality system holds its reports, and the Manufacturing Execution System (MES) maintains its genealogy records. These isolated data sets rarely come together in a cohesive, contextualized way that an AI system can effectively leverage for meaningful insights. The result is a fragmented understanding of the production process, where correlations are difficult to identify and root cause analysis is a time-consuming manual effort. By creating a unified data ecosystem, SpaceX can train its AI on multi-source information that is both connected and contextualized. This transforms the role of AI from a simple reporting tool that analyzes past events into a powerful, proactive engine for real-time control and optimization. It enables the system to understand not just what happened, but why it happened and what is likely to happen next, unlocking a level of predictive capability that is impossible to achieve with siloed data. This holistic data advantage is the fundamental building block for creating a truly intelligent and autonomous factory.

From Reactive Alerts to Predictive Diagnostics

One of the most immediate and practical impacts of this deep integration of AI will be a complete revolution in how factories detect and respond to process anomalies. The current industry standard for anomaly detection often amounts to little more than a simple, uninformative alert—for example, a notification that a specific parameter has drifted outside its predefined limits. Such an alert typically triggers a lengthy and resource-intensive investigation by engineers, who must manually sift through disparate data logs and conduct experiments to diagnose the root cause of the problem. This reactive process is inefficient, leading to extended downtime, increased scrap rates, and delays in production schedules. It forces skilled personnel to spend their time firefighting immediate problems rather than focusing on proactive process improvement and innovation. The inherent latency in this approach means that by the time an issue is identified and resolved, significant resources may have already been wasted.

With AI trained across multimodal production data, this entire process becomes vastly more intelligent, efficient, and proactive. The new system will be able to identify subtle process drifts and complex patterns long before they escalate into critical issues that would trigger a conventional alarm. It can automatically correlate these patterns across different machines, production cells, and operational stages, providing a holistic view of the factory’s health. Instead of just flagging a problem, the AI will be able to surface the likely root causes in minutes, drastically reducing diagnostic time from days or even weeks. Over time, this system will evolve from being merely diagnostic to being fully predictive and prescriptive. It will not only identify what is currently out of spec but will also alert operators to what is about to go out of tolerance, explain the underlying reasons why, and recommend specific, validated corrective actions. This enhanced capability allows factories to shift from a reactive stance of managing failures to a proactive one of continuously managing the health of their automated processes.

Creating a Framework for Trust and Integration

Driving Compliance and Governance in AI

The integration of advanced AI into a highly regulated and safety-critical field like aerospace manufacturing will inevitably force the maturation of AI governance and compliance frameworks. Rocket production operates under extremely stringent quality and safety standards, such as AS9100, which do not permit the use of “black box” systems that make uncontrolled or untraceable changes to the manufacturing process. Every decision, adjustment, and output must be justifiable, verifiable, and auditable. This intense regulatory pressure means that as SpaceX embeds AI deeper into its operations, it must simultaneously develop and implement sophisticated systems that support full data lineage, providing complete traceability of information from its source through all subsequent transformations and analyses. This requires a level of transparency and accountability that goes far beyond what is typically required in less regulated consumer or enterprise applications of AI.

This necessity is exceptionally beneficial for the broader manufacturing world. The slow adoption of AI in many industries, particularly in sectors like pharmaceuticals, medical devices, and automotive manufacturing, has been significantly hampered by legitimate concerns over trust, traceability, and regulatory compliance. By building and validating robust governance frameworks within one of the world’s most demanding regulatory environments, SpaceX will create a proven blueprint for safe, transparent, and compliant AI. This framework will include robust versioning, validation, and approval workflows for AI models; the implementation of Explainable AI (XAI) techniques to provide clear, understandable justifications for AI-driven decisions; mandatory human-in-the-loop controls for high-risk decisions; and comprehensive, immutable audit trails for compliance reviews. The resulting systems will demonstrate how to harness the power of AI while maintaining the rigorous oversight required in mission-critical applications, paving the way for wider adoption across all regulated industries.

Unifying AI Layers for True Autonomy

Ultimately, this integration is projected to be the catalyst that finally connects the currently disconnected layers of AI within the manufacturing stack, enabling a transition from isolated automation to true, holistic autonomy. Achieving a fully autonomous production environment requires seamless coordination and communication across multiple, distinct levels of intelligence. The first is the physical AI, which is the embodiment of intelligence in the robots, machines, and equipment performing physical tasks on the factory floor. The second is the Edge AI, which involves real-time decision-making and inference at the local machine or cell level, responsible for immediate process coordination and safety-critical functions. The third and highest level is Industrial AI, which operates at the plant and enterprise level to handle fleet-wide learning, prescriptive optimization of the entire production flow, and the development of predictive agentic models that can anticipate future needs and challenges.

In most current implementations, these layers operate in relative isolation, creating informational and operational silos that limit the potential of the overall system. By integrating these layers into a cohesive whole, SpaceX can create a continuous, virtuous feedback loop. Learning that occurs at the factory level can be used to refine control algorithms at the individual machine level, while real-world performance data from the factory floor is continuously fed back to retrain and improve the higher-level models. This constant, bidirectional flow of information is the essential mechanism that transforms a collection of siloed automated tasks into a singular, intelligent, and scalable autonomous system. It enables the entire factory to learn and adapt as a unified entity, optimizing not just individual processes but the entire value chain. This unified approach is the final, crucial step in realizing the vision of a factory that is not just automated, but truly autonomous.

The Accelerated Path to an Autonomous Future

The strategic union of SpaceX’s manufacturing prowess and xAI’s intelligence capabilities was a clear confirmation of the industry’s trajectory, establishing new norms built around AI-enabled, software-defined automation. This “forcing function” decisively shortened the timeline for the widespread adoption of truly autonomous manufacturing. The initiative drove the rapid development of standardized data architectures, the embedding of AI directly into robotic applications, and the replacement of static programming with dynamic, closed-loop control systems. While SpaceX’s facilities served as the initial proving grounds, the resulting architectures, compliance frameworks, and practical applications for closed-loop autonomy have already had a far-reaching impact. This acquisition was not a futuristic vision but a seminal moment that accelerated the journey toward a future where factories became not just automated, but fully autonomous systems capable of continuous learning, self-optimization, and real-time orchestration.