The promise of collaborative automation has often been tethered to a fixed point, limiting the vast potential of these intelligent machines to the reach of their own articulated arms. The Movotrak CTU (cobot transfer unit) represents a significant advancement in collaborative automation, designed to sever that tether and unleash new possibilities. This review will explore the evolution of this technology, its key features, performance metrics, and the impact it has on modern manufacturing applications. The purpose of this review is to provide a thorough understanding of the technology, its current capabilities, and its potential for future development.

An Introduction to the Movotrak 7th Axis

The Thomson Movotrak CTU emerges as a comprehensive solution engineered to extend the linear range of collaborative robots, directly addressing one of their most significant operational constraints. The core principle is simple yet transformative: by adding a seventh axis of linear motion, the system overcomes the inherent workspace limitations of a stationary cobot. This expansion allows a single robotic arm to travel significant distances, multiplying its utility and fundamentally altering the economic calculations behind its deployment.

In the broader automation landscape, the system’s relevance is defined by three primary value propositions that cater to the evolving needs of modern industry. First is a revolutionary approach to advanced safety, which is paramount in any environment where humans and robots work in close proximity. Second is the dramatically expanded operational capability, which translates directly into a greater return on investment (ROI) by maximizing the productivity of a single cobot. Finally, the system emphasizes streamlined integration, lowering the barrier to entry for businesses looking to adopt more dynamic and flexible automation solutions.

Core Features and Technical Breakdown

A Multi-Layered Approach to Collaborative Safety

The Movotrak establishes a new benchmark for safety in extended-range collaborative systems through an advanced, dual-layer collision detection system. The first layer is hardware-based, featuring a highly sensitive load cell integrated directly into the moving carriage that houses the cobot. This physical sensor is calibrated to detect direct contact with an obstacle or person with as little as 13 Newtons of force, ensuring an immediate and protective stop command is issued upon physical interaction. This provides a foundational level of safety that is always active and independent of software.

Complementing the hardware is a patent-pending, software-based layer that provides comprehensive protection along the entire axis. This system employs a proprietary algorithm to continuously monitor the servo motor’s current draw in real time. By intelligently correlating the motor’s energy consumption with the carriage’s known position and expected resistance, the system can instantly detect abnormalities that signify a collision. To further enhance its collaborative credentials, the system incorporates a crucial post-collision reverse-move function, which automatically retracts the unit slightly after a halt to eliminate dangerous pinch points. Critically, all safety logic is processed on a dedicated Thomson drive, ensuring that these vital functions operate with maximum responsiveness without competing for the robot’s primary processing resources.

Dramatically Expanding Cobot Reach and ROI

The most immediate benefit of the Movotrak system is its ability to enhance a cobot’s productivity and economic value. The system is capable of extending a cobot’s operational envelope by up to 10 meters, transforming it from a localized tool into a factory-floor asset with far-reaching capabilities. This significant extension in range does not compromise on precision; the unit maintains a remarkable accuracy of ±25 microns over its entire travel distance, making it suitable for even high-precision tasks like inspection and intricate assembly.

This expanded reach is the key to unlocking a powerful financial benefit: hardware consolidation. A single cobot mounted on a 7th axis can perform tasks that would otherwise require multiple stationary robots, such as tending a long line of CNC machines or palletizing across a large area. This ability to do more with less drastically reduces the initial capital expenditure on robotic hardware and simplifies the overall automation architecture, leading to a much stronger and faster ROI on the initial cobot investment. The system’s physical versatility further amplifies its value, with options for horizontal, inverted, or wall-mounted configurations that allow it to be adapted to nearly any factory layout.

Streamlined Integration and Simplified Programming

Recognizing that complexity is a major barrier to automation adoption, the Movotrak system is engineered for user-friendly integration and operation. It is designed for compatibility with a wide array of cobot brands and sizes, ensuring it can be deployed in diverse manufacturing ecosystems. For Universal Robots, one of the most prevalent cobot platforms, this integration is made seamless through a certified URCap software plug-in. This dedicated software allows all programming and control of the 7th axis to be managed directly through the familiar UR Teach Pendant, eliminating the need for operators to learn a new interface.

Further simplifying the setup process is the innovative Freedrive function, a feature that mirrors the hand-guidable convenience of a cobot’s joints. This functionality allows an operator to manually and effortlessly slide the carriage and its mounted cobot along the entire length of the axis to program waypoints by hand. Instead of tedious jogging via a teach pendant, the user can physically move the robot to a desired position and register that location with the push of a button. This capability drastically reduces the programming time required for complex, multi-point tasks and makes the system accessible even to users with limited robotics experience.

Recent Developments and System Enhancements

The trajectory of 7th-axis technology is marked by a continuous push toward greater interoperability and accessibility. A key recent development for the Movotrak system is the ongoing expansion of its brand compatibility, with planned support for Fanuc cobots set to join the existing integrations for Universal Robots and ABB. This move reflects a broader industry trend away from closed, proprietary systems and toward open, flexible platforms that give end-users more choice in designing their automation solutions.

This evolution is indicative of a larger shift in the automation market. As collaborative technologies mature, the focus is increasingly on making sophisticated systems more adaptable and easier to deploy in a wider range of manufacturing environments, from small workshops to large-scale industrial facilities. By prioritizing multi-brand support and certified software integrations, technologies like the Movotrak are helping to democratize advanced automation, empowering more businesses to leverage its benefits.

Key Applications in Modern Manufacturing

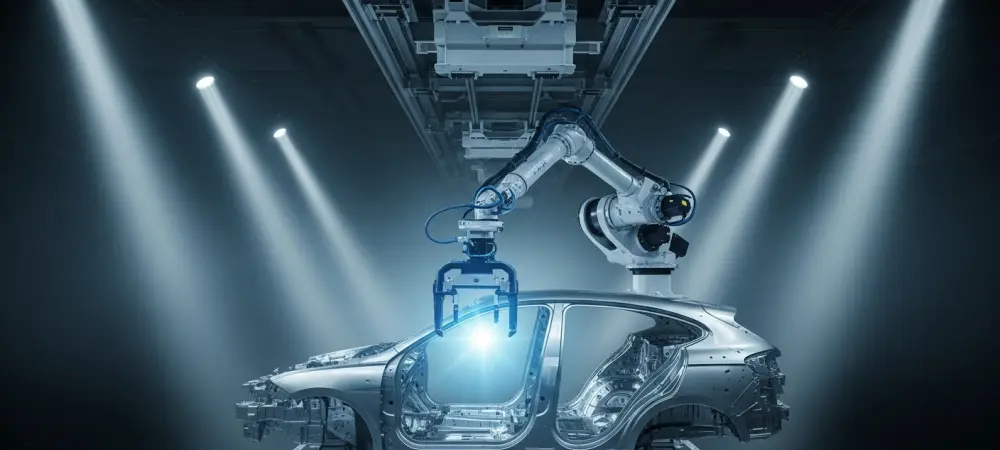

The practical value of the Movotrak CTU is best illustrated through its real-world applications across various industries. In logistics and packaging, the system is being successfully deployed for large-scale palletizing operations, where a single cobot can now build and manage multiple pallets spread across a wide area. In quality control, the extended reach is unlocking new possibilities for comprehensive welding inspections on large components, such as automotive chassis or aerospace structures, allowing a single inspection robot to cover vast surfaces with high precision.

Another prominent use case is in machine tending, particularly in automotive assembly lines and machine shops. Here, one cobot on a 7th axis can service multiple machines or production stations, loading and unloading parts or transferring work-in-progress between different stages of a process. These examples demonstrate how the combination of extended reach and collaborative safety unlocks new efficiencies and applications that were previously impractical or impossible for a single, fixed-base cobot.

Current Challenges and Ongoing Mitigations

Despite its technological advancements, the adoption of 7th-axis technology faces certain hurdles. A primary challenge is overcoming market inertia and competing against incumbent automation solutions, which may be more familiar to established manufacturers. Additionally, the integration of a long-travel moving axis introduces new considerations for a facility’s overall safety risk assessment, requiring a more holistic approach than a standard stationary cobot installation. The initial investment cost, while offset by a strong ROI, can also be a barrier for some businesses.

To address these limitations, development efforts are focused on simplifying the user experience and broadening market appeal. The creation of certified software plug-ins, such as the URCap for Universal Robots, is a direct mitigation for integration complexity, as it standardizes and streamlines the setup process. Furthermore, by continually expanding support for more cobot brands, the technology becomes a more viable and attractive option for a larger segment of the market, helping to accelerate its adoption and prove its value proposition against more traditional automation systems.

The Future of Extended-Range Cobot Automation

Looking ahead, 7th-axis technology is poised to evolve in several exciting directions. Future developments will likely include the integration of more advanced sensors, such as vision systems and LiDAR, directly into the linear axis for enhanced environmental awareness and obstacle avoidance. This could be coupled with improved AI-driven path planning, allowing the system to autonomously navigate more complex and dynamic environments with greater efficiency and safety. The possibility of multi-axis systems, combining linear travel with vertical or rotational motion, could offer even greater freedom of movement.

The long-term impact of this trajectory is a fundamental shift in how collaborative robots are perceived and utilized. They will increasingly move from being fixed-base tools dedicated to a single task to becoming highly mobile and versatile automation assets that can be dynamically deployed wherever they are needed on the factory floor. This transition promises to create more flexible, resilient, and productive manufacturing operations.

Conclusion A Definitive Review

The Thomson Movotrak CTU proved to be a transformative technology that successfully addressed critical limitations in collaborative automation. Its design represented a thoughtful and comprehensive approach to extending a cobot’s utility far beyond its static base. By excelling in the crucial areas of safety, performance, and usability, the system distinguished itself as a mature and robust solution for modern manufacturing challenges.

The multi-layered safety system delivered a level of confidence required for true human-robot collaboration over extended distances. The combination of long-range travel and high precision unlocked significant ROI potential through hardware consolidation and new application possibilities. Ultimately, the system established itself as a “true collaborative extension,” fundamentally enhancing a cobot’s reach, intelligence, and value in the modern industrial landscape.