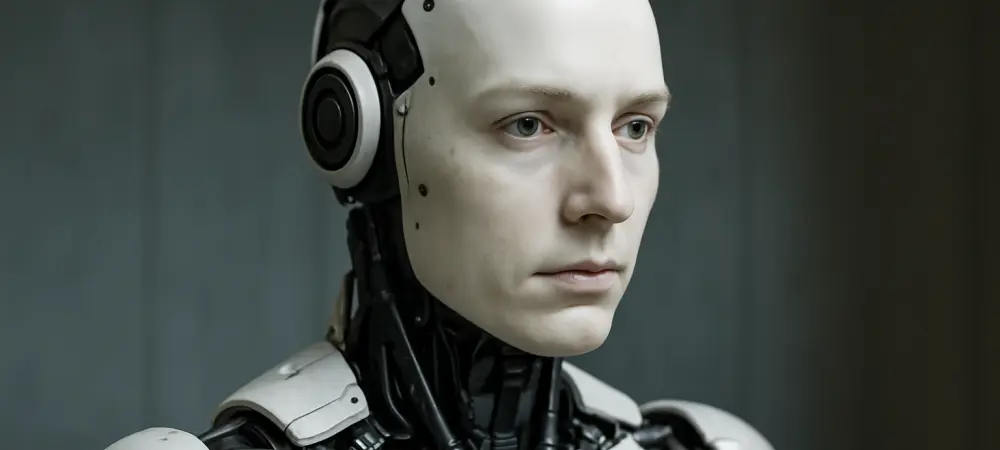

In the realm of industrial automation, few innovations ignite the imagination more vividly than advances in robotic autonomy. Consider the Walker S2—a humanoid robot capable of autonomously changing its own batteries. Envision a factory setting where operations persist seamlessly, uninhibited by the need for human intervention in routine tasks such as battery replacement.

A Leap Toward Continuous Industrial Operations

The significance of the Walker S2 cannot be overstated in a world increasingly relying on automation. As industries aspire to achieve 24/7 operational capacity, the ability for robots to manage their energy needs independently becomes indispensable. This increasing demand is reflected in global trends, with robot density reaching unprecedented levels. In such an environment, the need for operational efficiency, cost savings, and innovation becomes even more evident, setting the stage for transformative advancements like the Walker S2.

Distinctive Features That Set Walker S2 Apart

What truly distinguishes the Walker S2 is its ingenious dual-battery system, enabling continuous operation. Standing at 5’3″ and weighing 95 pounds, its design incorporates 20 degrees of freedom, lending it remarkable maneuverability. Equipped with Wi-Fi and Bluetooth, the robot can be integrated seamlessly into various industrial environments. Its two-hour walking or four-hour standing battery cycles ensure uninterrupted performance, potentially revolutionizing sectors ranging from manufacturing to logistics.

Expert Validation: Technological Milestone in Robotics

Experts within the field of robotics herald the Walker S2 as a significant leap forward. They recognize the potential impact of autonomous energy management on the future landscape of robotics. Research supports these claims, demonstrating marked improvements in efficiency when robots like Walker S2 autonomously handle their energy needs. Industry leaders and early adopters echo these sentiments, noting the robot’s role in streamlining operations and reducing energy management bottlenecks.

The Path Forward: Integration and Challenges

Integrating the Walker S2 into existing frameworks involves several practical steps. Industries need to evaluate current processes and align them with the capabilities of the Walker S2. Strategies, therefore, involve adapting infrastructures and training personnel to effectively utilize this technology. While challenges such as initial costs and integration complexities exist, a comprehensive approach can lead to fruitful implementation, thereby maximizing the benefits of such robotic innovations. The forward-looking existence of the Walker S2 in factories envisioned a new era in industrial autonomy. It opened up possibilities for enhanced efficiency, cost savings, and innovation. As industries plan to incorporate such technologies, the Walker S2 stands as a testament to advances that fuel growth and progress. Its introduction represents a pivotal moment in reshaping how industries operate, laying the groundwork for future innovations.