As we approach 2025, automation is revolutionizing various sectors, significantly altering business operations, enhancing efficiency, and opening up new opportunities. These advancements are driving smarter industries and transforming the global economy. With rapid progress in technology, industries are adopting automation to stay competitive and meet the evolving demands of consumers. This article delves into the key trends and innovations shaping the future of automation, examining the integrated use of artificial intelligence, hyperautomation, and the Industrial Internet of Things, among others.

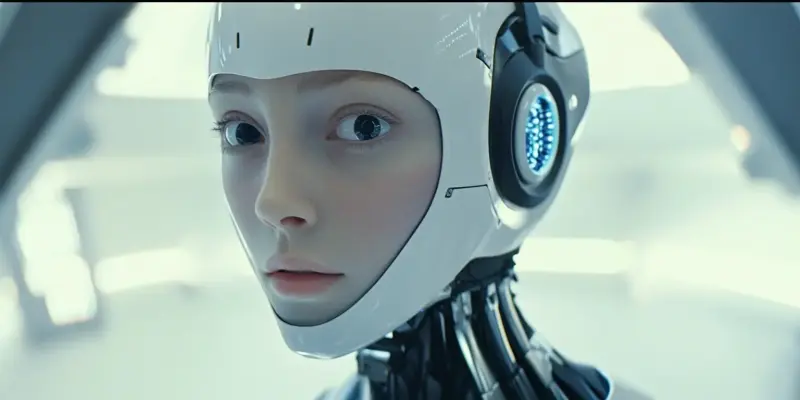

Artificial Intelligence-Powered Automation

Artificial Intelligence (AI) integration in automation is advancing rapidly, enabling systems to perform tasks without human intervention by learning, adapting, and optimizing processes. This smart automation is particularly impactful in industries such as manufacturing, healthcare, and finance. AI-powered automation is employed for predictive analytics to prevent equipment failures, intelligent decision-making in supply chain management, and personalized customer experiences through AI chatbots and virtual assistants. By leveraging machine learning, AI reduces downtime and improves operational efficiency, making automation smarter and more effective. The ability of AI to learn and adapt ensures continuous improvement in automated processes, leading to enhanced productivity and cost savings.

In the manufacturing sector, AI-driven automation enhances production lines by predicting equipment malfunctions and optimizing maintenance schedules, reducing unexpected downtimes. In healthcare, AI-powered diagnostic tools enable faster and more accurate detection of diseases, improving patient outcomes. Financial institutions leverage AI for fraud detection and risk management, providing a more secure environment for transactions. The transformative potential of AI in automation signifies a paradigm shift, with industries embracing these technologies to remain agile and competitive in an ever-evolving market.

Hyperautomation

Hyperautomation, the concept of automating as many business processes as possible, is becoming a strategic priority for organizations. By combining technologies like Robotic Process Automation (RPA), AI, and machine learning, businesses can streamline workflows, enhance employee productivity by automating repetitive tasks, and gain deeper insights through advanced data processing. Industries such as banking and insurance are at the forefront of hyperautomation, aiming to improve customer service and operational speed. The integration of multiple automation technologies allows for more comprehensive and efficient business processes, ultimately leading to better outcomes for both companies and their customers.

The implementation of hyperautomation in the banking sector, for instance, enables faster processing of transactions, reducing the need for manual intervention and minimizing errors. Insurance companies use hyperautomation to automate claims processing, resulting in quicker resolutions and improved customer satisfaction. The combination of RPA and AI not only automates routine tasks but also provides valuable insights through data analysis, enabling companies to make informed decisions. Hyperautomation’s overarching objective is to create a more streamlined and efficient operational framework, fostering innovation and driving business growth.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is transforming automation in manufacturing and logistics by connecting devices, sensors, and systems. Key applications of IIoT-enabled automation include smart factories with automated production lines, real-time tracking of assets and inventory, and enhanced predictive maintenance to reduce costs and downtime. IIoT is propelling the shift to Industry 4.0, resulting in more responsive and efficient factories. The interconnected nature of IIoT allows for seamless communication between devices, leading to improved coordination and optimization of industrial processes.

In a smart factory setting, IIoT sensors and devices monitor production parameters in real-time, providing actionable data to optimize operations and ensure product quality. The logistics industry benefits from IIoT through real-time tracking of shipments, enhancing visibility and ensuring timely deliveries. Predictive maintenance, enabled by IIoT, reduces unexpected equipment failures by identifying potential issues before they escalate, lowering maintenance costs and improving overall equipment reliability. By embedding IIoT technology into their operations, manufacturers and logistics providers can achieve unprecedented levels of efficiency and responsiveness.

Autonomous Systems

Autonomous technologies are gaining momentum across various sectors, including transportation, agriculture, and retail. Examples of autonomous systems include self-driving vehicles for logistics and personal use, automated drones for agricultural monitoring and delivery, and AI-powered inventory management systems in retail stores. These technologies address labor shortages and increase precision by minimizing reliance on human intervention. The adoption of autonomous systems leads to more efficient operations and can significantly reduce the risk of human error, enhancing overall productivity and safety.

In the transportation sector, self-driving vehicles streamline logistics by autonomously navigating routes and delivering goods with high efficiency, reducing the need for human drivers. Agriculture benefits from autonomous drones that monitor crop health, optimize irrigation, and apply pesticides with precision, improving yields and reducing resource wastage. Retail stores use AI-powered inventory management systems that autonomously track inventory levels, reorder products, and manage stock locations, ensuring that shelves are always stocked and reducing customer waiting times. The growing ubiquity of autonomous systems promises a future where tasks are performed with greater accuracy and consistency, transforming industries through innovative approaches.

Healthcare Automation

The healthcare sector is undergoing significant transformation with the adoption of automation. Automation in healthcare extends to administrative tasks, diagnostics, and patient care. It is used to improve diagnostics through AI algorithms, manage hospital workflows efficiently, and enhance patient monitoring with IoT-enabled devices. Innovations such as robotic surgery, telemedicine platforms, and automated medication dispensers exemplify how automation is enhancing healthcare delivery. These advancements lead to better patient outcomes, reduced operational costs, and more efficient use of healthcare resources.

AI-driven diagnostic tools assist healthcare professionals in accurately identifying diseases, leading to early intervention and improved patient outcomes. Automated hospital workflows, such as appointment scheduling and patient records management, streamline administrative processes and reduce the burden on healthcare staff. IoT-enabled devices monitor patients’ vital signs in real-time, providing continuous health data and alerting medical personnel to any anomalies. Robotic surgery introduces precision and minimizes invasiveness, resulting in quicker recovery times. Telemedicine platforms allow remote consultations, expanding access to healthcare services. These automated solutions enhance the efficiency and quality of healthcare delivery, making it more accessible and effective.

Sustainable Automation

As industries increasingly focus on sustainability, automation plays a crucial role in minimizing environmental impact. Companies leverage automation for energy-efficient manufacturing processes, waste reduction through optimized resource management, and integration of renewable energy systems in industrial operations. Sustainable automation aligns with global goals to reduce carbon footprints while ensuring profitability. The adoption of green technologies and practices in automation helps companies meet regulatory requirements and appeal to environmentally conscious consumers.

Energy-efficient manufacturing processes utilize advanced automation systems to optimize resource usage, reducing energy consumption and waste. Automated control systems manage power usage more effectively, minimizing unnecessary energy expenditure. Waste reduction through automation involves precise material handling and recycling, ensuring that resources are used judiciously and environmental impact is minimized. The integration of renewable energy systems, such as solar panels and wind turbines, into automated industrial processes further enhances sustainability by reducing dependency on fossil fuels. Embracing sustainable automation not only supports environmental goals but also enhances a company’s reputation, making it a preferred choice for eco-conscious consumers.

Cloud-Based Automation Solutions

Cloud computing is making automation more accessible and scalable. Cloud-based platforms enable businesses to deploy tools quickly without significant infrastructure investments, integrate seamlessly with other digital systems, and ensure data security and compliance. This trend benefits particularly small and medium-sized enterprises (SMEs) looking to automate without substantial upfront costs. The flexibility and scalability of cloud-based solutions allow businesses to adapt to changing needs and grow their automation capabilities over time.

For SMEs, cloud-based automation offers a cost-effective way to leverage advanced technologies without the need for extensive IT infrastructure. Businesses can access automation tools on a subscription basis, scaling their usage according to demand. Cloud-based solutions also facilitate seamless integration with existing digital ecosystems, ensuring cohesive and efficient operations. Data security and compliance are paramount in cloud-based platforms, with robust measures in place to protect sensitive information. The adaptability of cloud-based automation solutions enables businesses to remain agile, responding swiftly to market changes and evolving customer demands, ultimately driving growth and innovation.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside humans, distinguishing them from traditional industrial robots. In manufacturing and logistics, cobots perform repetitive tasks, allowing humans to focus on complex activities, improve workplace safety by handling hazardous jobs, and increase productivity in hybrid workflows. Cobots effectively bridge the gap between human creativity and machine efficiency. Their ability to work safely alongside human workers makes them a valuable asset in various industries, enhancing overall operational efficiency.

In manufacturing, cobots assist in tasks such as assembly, welding, and material handling, working alongside human operators to increase precision and efficiency. Logistics companies utilize cobots for order picking, packing, and sorting, streamlining processes and reducing the likelihood of errors. The incorporation of cobots in hazardous environments, such as chemical manufacturing or heavy machinery operations, improves workplace safety by reducing human exposure to dangerous tasks. By complementing human skills with robotic efficiency, cobots facilitate a more productive and safe working environment, ultimately driving innovation and growth in various sectors.

Edge Computing and Real-Time Automation

Edge computing facilitates real-time decision-making in automated systems by processing data closer to its source. Various industries use edge computing to enhance robotics in manufacturing, enable faster responses in autonomous vehicles, and optimize energy consumption in smart grids. By reducing latency and dependence on centralized systems, edge computing increases the speed and reliability of automation. This technology is crucial for applications that require immediate data processing and response, ensuring optimal performance and efficiency.

In manufacturing, edge computing enables real-time monitoring and control of automated production lines, allowing for instant adjustments to maintain quality and efficiency. Autonomous vehicles rely on edge computing for split-second decision-making, enhancing navigation and safety. Smart grids use edge computing to optimize energy distribution and consumption, responding dynamically to changes in demand and supply. The ability to process data locally means that automated systems can operate with minimal delays, leading to more accurate and efficient outcomes. The implementation of edge computing in automation promises a future where industries can achieve higher levels of performance and responsiveness.

Workforce Transformation

As automation continues to advance, it is driving a profound transformation in the workforce. Jobs are evolving to require new skills, with an increased focus on digital literacy and the ability to work alongside automated systems. Employers are investing in training and upskilling programs to prepare their employees for the changing landscape. The collaboration between humans and machines is becoming essential, with workers taking on more strategic and creative roles as automation handles repetitive and data-intensive tasks. This shift is reshaping the job market, creating opportunities for innovation and growth while ensuring that the workforce remains relevant and capable in an automated world.