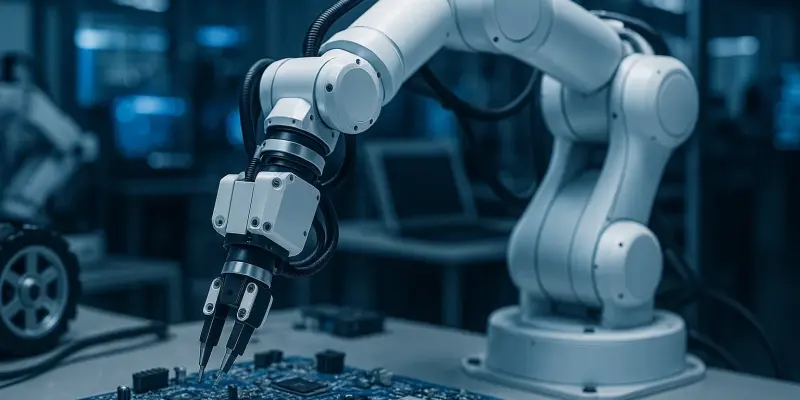

In the dynamic landscape of robotics technology, Universal Robots has taken a monumental leap forward with the introduction of a low-level Direct Torque Control Interface across its entire lineup of collaborative robots, or cobots. This innovative feature caters to both developers seeking smarter AI-driven applications and researchers desiring enhanced precision in robotic interactions with the environment. By addressing key challenges in force regulation, this advancement is poised to revolutionize sectors requiring meticulous control such as screwdriving, part insertion, and assembly. The significance of this development lies in its ability to enable precise control of torque at the joint level, an achievement historically challenging and resource-intensive.

Revolutionizing Torque Control in Robotics

Removing Barriers with Direct Torque Control

Universal Robots has transformed the process of exerting delicate control over cobot joints with its Direct Torque Control Interface, facilitating users to set target torque values at a robust control frequency of 500 Hz. This milestone effortlessly integrates into the company’s existing automation software, including PolyScope 5 and PolyScope X. Designed to support all UR cobot models, including notable series like the e-Series and UR Series, this system simplifies what once was a sophisticated and demanding software endeavor. The introduction of this torque control technology means that developers and researchers can bypass typically cumbersome tasks of custom hardware development, thereby accelerating advancements in robotic responsiveness.

By allowing cobots to react dynamically to physical interactions in real-time, the Direct Torque Control centers torque as the fundamental input, transforming the way these machines perform intricate tasks. Such capacity enables cobots to finely calibrate their actions, preventing incorrect alignments or the application of excessive pressure. This heightened level of control is integral in environments requiring impeccable alignment or force, significantly enhancing robots’ ability to interact contextually with their surroundings. The availability of this interface signifies a pivotal shift toward more perceptive and precise robotics, embodying current trends steering robotic systems toward advanced perceptive abilities.

Practical Applications and Industry Examples

The profound impact of Universal Robots’ Direct Torque Control Interface is exemplified by its integration into NVIDIA Robotics research. In a project focusing on robotic assembly, NVIDIA engineers utilized the UR10e cobot equipped with this new interface to accomplish a complex gear assembly task without painstaking fine-tuning. Highlighting the interface’s efficacy, this initiative employed impedance control, permitting seamless transitions from simulated to real-world environments, a testament to the interface’s robustness. This achievement underscores the potential of integrating advanced control methodologies into routine robotic functions, paving the way for unparalleled efficiency and adaptability.

The approach taken by NVIDIA’s team is illustrative of the strategic value offered by Universal Robots’ interface. By employing Isaac Lab—a robust, open-source robotic training framework—engineers successfully trained the UR10e cobot in an array of skills necessary for the assembly task. They leveraged reinforcement learning for motion generation and utilized neural networks with long short-term memory (LSTM), trained through the Proximal Policy Optimization (PPO) algorithm. This combination enabled the development of advanced control policies capable of generalizing complex tasks across varied conditions. Such implementations demonstrate the potential of Universal Robots’ innovations in streamlining robotic research and amplifying cobot capabilities across industries.

Technological Synergy and Future Perspectives

Impactful Collaboration and Emerging Capabilities

The collaboration between Universal Robots and NVIDIA through the utilization of the Direct Torque Control Interface marks a meaningful step in the robotics domain. By making advanced control features standard, Universal Robots eliminates one of the significant barriers developers face when implementing cutting-edge control strategies. Rather than focusing on constructing bespoke hardware or firmware for testing robot compliance in intricate scenarios, developers can turn their attention to designing robots with intelligent, adaptive features. This shift is vital as robotic systems progressively navigate more unstructured or contact-intensive environments, underscoring a new direction where robots can become increasingly autonomous and versatile.

The Direct Torque Control Interface further manifests Universal Robots’ commitment to maintaining a technological edge, aligning with broader industry movements toward intelligent robotic systems. As the sector continues to embrace innovations, developers are equipped with powerful tools to forge uncharted territories in robotics. By standardizing the integration of AI-driven functionalities, robotic systems are poised for enhanced accuracy, reliability, and flexibility, mirroring the ever-evolving demands of industries around the globe. These developments not only optimize current operations but also lay the groundwork for unprecedented innovations and applications in future contexts.

A Gateway to Future Innovations

In the ever-evolving field of robotics, Universal Robots has made a groundbreaking advancement with the launch of a Direct Torque Control Interface across its full range of collaborative robots, commonly referred to as cobots. This cutting-edge feature is tailored for developers who are crafting smarter AI-driven solutions and researchers aiming for greater precision in how robots interact with their surroundings. By tackling significant challenges in force regulation, this innovation is set to transform industries demanding precise control, including those involved in screwdriving, part insertion, and various assembly tasks. The crux of this development is its capacity to provide exact torque control at the joint level. Historically, accomplishing such a level of precision has been demanding and intensive in terms of resources. This new interface not only elevates the functionality of cobots but also opens new doors for applications where meticulous attention to force and movement is paramount, marking a significant technological leap in robotics.