The era of industrial robots operating blindly within meticulously structured environments is rapidly drawing to a close, replaced by a new generation of machines endowed with the sophisticated ability to see, comprehend, and intelligently adapt to the dynamic world around them. This transformative shift, fueled by the convergence of advanced optics, artificial intelligence, and powerful processing, is moving automation beyond simple, repetitive tasks. Intelligent vision has become a cornerstone technology driving the ambitions of Industry 4.0, enabling the flexibility required for high-mix manufacturing, and unlocking new frontiers in advanced automation. This analysis will explore the market drivers, real-world applications, expert insights, and future trajectory of this powerful technological convergence.

The Rise of Visually-Aware Robotics

From Simple Sensors to Intelligent Systems: Market Growth and Evolution

The market for vision-guided robotics (VGR) is experiencing exponential growth, reflecting a fundamental shift in manufacturing philosophy. Projections indicate a robust expansion in adoption rates across key sectors from 2026 through the end of the decade, as industries move from pilot programs to full-scale integration. This surge is not merely about adding cameras to robots; it represents a complete evolution in capability. The transition from rudimentary vision systems—once limited to basic presence or absence detection—to today’s intelligent platforms marks a significant leap in industrial technology.

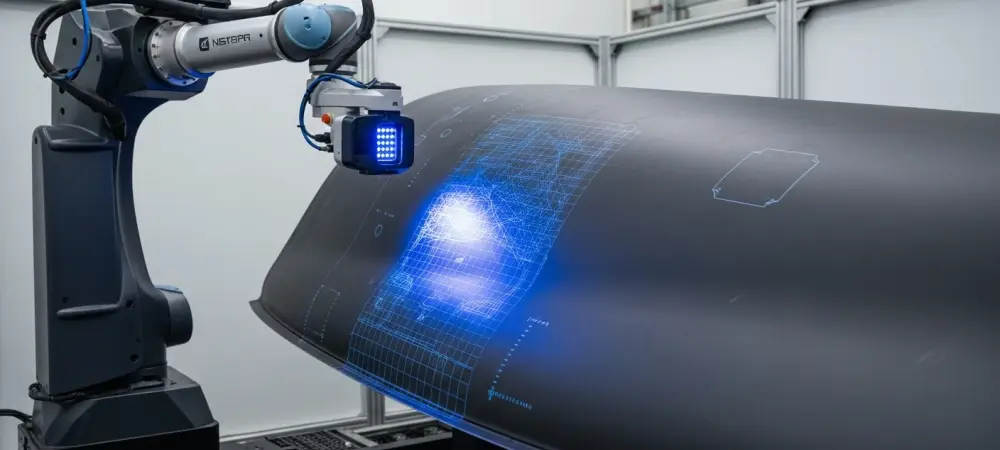

In contrast to historical systems that operated on simple, rule-based logic, modern robotic vision is powered by a confluence of high-resolution 3D imaging, edge AI, and deep learning algorithms. Technologies like laser triangulation and structured light provide robots with rich spatial awareness, allowing them to perceive depth, shape, and volume with remarkable accuracy. This detailed understanding of three-dimensional space, processed in real time at the edge, empowers robots to move beyond pre-programmed paths and engage with their environment dynamically.

This technological maturation has elevated vision from a simple guidance tool to a sophisticated measurement and control system. Robots equipped with these advanced sensors can now perform metrology-grade measurements as an integrated part of their workflow, verifying dimensional accuracy on the fly. This ability to measure and make instantaneous decisions closes the loop between action and verification, effectively turning the robot into a mobile, quality-aware platform that executes its task and validates its own work simultaneously.

Intelligent Vision in Practice: Applications Across Industries

The most profound impact of vision-guided robotics is seen in the push toward high-mix, low-volume (HMLV) production. Traditional automation falters when faced with variability, but intelligent vision thrives on it. By giving robots the ability to perceive and adapt, manufacturers can handle randomly oriented parts in a bin or on a conveyor, eliminating the need for costly and inflexible mechanical fixturing. This adaptability allows production lines to switch between different product models with minimal downtime, as the vision system can be reconfigured through software rather than physical retooling.

This flexibility is proving indispensable across a range of high-stakes industries. In the automotive sector, vision systems guide robots in the precision assembly of complex EV battery modules and enable adaptive welding by tracking seams in real time to compensate for part variations. Similarly, the aerospace industry relies on VGR for the delicate handling and inspection of uniquely shaped composite structures, where each component may have slight geometric deviations.

The benefits extend to industries defined by precision and miniaturization. In electronics manufacturing, intelligent vision guides robots to perform high-precision tasks on ever-shrinking components, a feat impossible with conventional automation. Likewise, in the medical device field, VGR ensures that strict quality and tolerance standards are met consistently across a diverse portfolio of products. In each of these applications, vision is not just an add-on; it is the core enabler of quality, flexibility, and efficiency.

Expert Insights on the AI and 3D Vision Convergence

The fusion of 3D vision with artificial intelligence is widely regarded as the catalyst for true process intelligence. This combination moves automation beyond a sequence of commands toward a state of genuine closed-loop control. With 3D vision providing a comprehensive geometric understanding of a part and its position, and AI interpreting that data with human-like nuance, robots can achieve a level of self-correction previously unattainable. They can now actively compensate for process drift, material variations, and unexpected events in real time. This evolution is fundamentally changing the operational paradigm from a “move and hope” model to a “measure, adjust, and execute” strategy. In the past, a robot would execute a pre-programmed path, and quality would be verified in a separate, downstream step. Today, a vision-equipped robot can scan a part, compare its actual geometry to the digital CAD model, and instantly adjust its tool path to compensate for any detected warpage or tolerance stacking. This integrated approach prevents defects from occurring rather than simply detecting them after the fact.

However, this powerful convergence also introduces new challenges, particularly in quality-critical applications. Experts emphasize the growing importance of metrological traceability and the explainability of AI models. For a vision system to be trusted in an aerospace or medical application, its measurements must be verifiable against established standards. Furthermore, the decision-making process of its AI algorithm must be transparent enough to be validated. Ensuring that these intelligent systems are not just effective but also reliable and accountable is a key focus for future development.

The Future Trajectory of Intelligent Robotic Vision

Looking ahead, the trajectory of robotic vision points toward an even deeper integration of sensory data and autonomous capabilities. The next wave of innovation will likely involve multi-sensor fusion, where visual data is combined with feedback from tactile and force sensors. This will give robots a more holistic understanding of their tasks, enabling them to handle delicate or complex objects with greater dexterity. Moreover, the development of self-calibrating systems will reduce deployment time and maintenance, allowing robots to adapt to new tasks and environments with minimal human intervention.

The role of artificial intelligence is also set to expand dramatically. The industry is moving toward the concept of globally trained AI models, where algorithms are trained on vast, diverse datasets from manufacturing facilities around the world. These large-scale models promise to deliver more robust and versatile performance, particularly in complex applications like cosmetic defect detection, where anomalies can be subtle and varied. This trend will further enable advanced concepts like fixtureless assembly, where vision systems become precise enough to guide robots through complex assembly sequences without any physical jigs.

Despite the promising outlook, significant challenges remain on the path to widespread adoption. Managing the immense volumes of data generated by high-resolution sensors at the edge requires powerful and efficient processing hardware. Overcoming difficult environmental conditions, such as variable lighting, shadows, and reflective surfaces, continues to be a focus of research and development. Perhaps most importantly, upskilling the workforce to manage, program, and maintain these sophisticated, multidisciplinary systems is crucial for realizing their full potential. The ultimate implication is clear: the lines between robots, inspection systems, and metrology devices are blurring, creating a new standard of embedded intelligence that will define the future of manufacturing.

Conclusion: A New Paradigm for Automation

The evolution of robotic vision marked a pivotal turning point in industrial automation. What began as a peripheral tool for simple guidance transformed into a core robotic sense, fundamentally redefining what machines could accomplish. This technology was instrumental in enabling a new era of manufacturing flexibility, allowing industries to move away from rigid mass production toward adaptable, high-mix operations. The integration of artificial intelligence acted as a powerful accelerant, transforming perception into understanding and making intelligent self-correction a reality.

Intelligent vision became an indispensable technology for the future of precision manufacturing, quality assurance, and autonomous systems. Its ability to provide real-time, data-driven feedback closed the loop between design, production, and inspection, creating smarter and more resilient supply chains. The journey from pre-programmed automation to visually-aware robotics ultimately demonstrated that when machines could measure, understand, and decide, they redefined the very concepts of productivity and innovation.