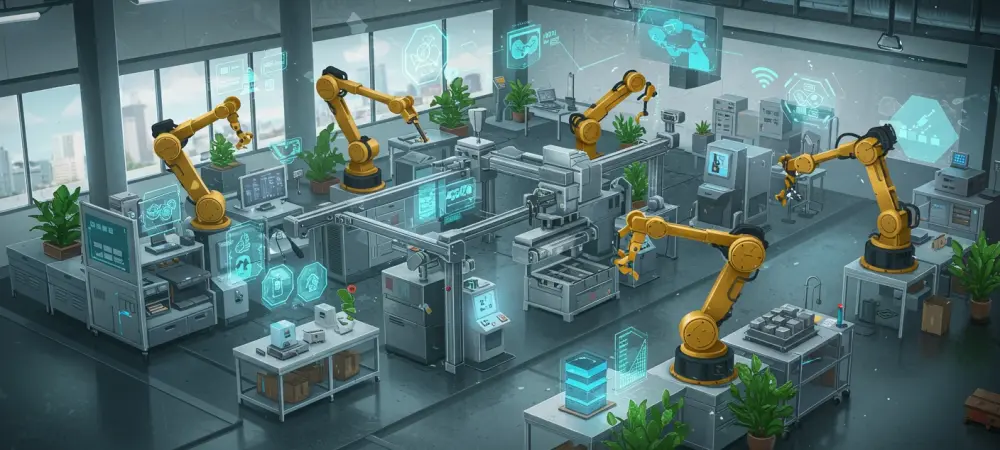

Imagine a world where industrial giants join forces to slash waste, empower innovators, and automate critical sectors with cutting-edge technology, creating a transformative impact across the globe. In 2025, this vision is a reality as strategic alliances reshape the manufacturing and technology landscape. The pressing challenges of sustainability, labor shortages, and technological scalability demand collaborative solutions, and industry leaders are stepping up through powerful partnerships. This roundup gathers insights, opinions, and tips from various industry perspectives to explore how these alliances are fueling progress in sustainability and automation, while comparing differing views on their impact and potential.

Exploring the Collaborative Push for Industrial Transformation

The Need for Strategic Alliances in Tackling Complex Challenges

The industrial sector today faces unprecedented hurdles, from managing excess inventory to addressing workforce gaps. Many industry observers note that no single entity can solve these issues alone, emphasizing the critical role of partnerships in pooling expertise and resources. Collaborative efforts are seen as a pathway to innovate faster, especially in areas like waste reduction and technological advancement.

A contrasting perspective highlights potential drawbacks, with some stakeholders cautioning that partnerships can sometimes dilute focus or create dependency on external players. Despite this, the consensus leans toward alliances as essential for scaling solutions that individual companies might struggle to achieve independently. The drive to balance profitability with broader societal goals often emerges as a central theme in these discussions.

Highlighting Key Partnerships Shaping the Industry

Several high-profile collaborations stand out in 2025, setting benchmarks for what strategic alliances can accomplish. Partnerships between companies like Phoenix Contact, Siemens, and Neura Robotics are frequently cited as examples of how diverse approaches can address distinct yet interconnected challenges. Industry voices agree that these alliances offer a blueprint for combining sustainability with cutting-edge automation.

However, opinions differ on which areas deserve the most focus, with some advocating for environmental initiatives and others prioritizing technological breakthroughs. This diversity in thought underscores the complexity of industrial transformation, where varied priorities must coexist to drive holistic progress.

Deep Dive Into Specific Collaborative Initiatives

Cutting Waste Through Sustainable Inventory Solutions

One widely discussed initiative involves Phoenix Contact USA and Waldom Electronics, focusing on reducing inventory waste in electronics distribution. Many industry analysts praise their approach of redistributing unused stock, which not only curbs financial losses but also supports environmental efforts like tree planting. This model is often highlighted as a practical step toward a carbon-neutral value chain.

On the flip side, some voices express skepticism about the scalability of such programs, pointing to slow adoption rates among distributors as a barrier. Concerns also arise about balancing profit motives with sustainability goals, with a few stakeholders suggesting that financial incentives might overshadow long-term environmental benefits. Despite these reservations, the initiative is largely viewed as a positive step. A recurring tip from industry perspectives is for companies to integrate similar redistribution models into their operations, ensuring that surplus materials find purpose rather than ending up as waste. This actionable advice resonates across sectors looking to align with greener practices.

Fostering Innovation Through Startup Support Ecosystems

Another focal point in 2025 is Siemens’ collaboration with Amazon Web Services under the Siemens for Startups program, launched at CES this year. Many industry commentators celebrate this effort for providing emerging companies with access to software tools, cloud services, and market opportunities. Examples like Arkisys in orbital manufacturing and EthonAI in waste reduction often surface as proof of the program’s diverse impact.

Differing opinions emerge on the risks of such initiatives, with some pointing to market saturation as a potential pitfall for startups vying for attention. Others note that unequal access to resources could disadvantage smaller players, creating an uneven playing field. These concerns contrast with the optimism surrounding rapid scaling opportunities for young innovators. Practical advice from various sources suggests that established firms should consider similar mentorship programs, offering technical and market support to nurture fresh talent. This strategy is seen as a way to inject innovation into traditional industries while building robust ecosystems for growth.

Advancing Automation With Cognitive Robotics in Key Markets

The partnership between Neura Robotics and Kenmec Mechanical Engineering garners significant attention for bringing humanoid robots to Asian industries like semiconductors and logistics. Industry feedback often highlights how this collaboration addresses acute labor shortages and economic pressures, positioning automation as a vital solution. The potential for global expansion is frequently mentioned as an exciting prospect.

However, not all views align, with some stakeholders challenging the notion that robotics merely replace human labor. Instead, they argue that AI-driven platforms enhance workplace safety and collaboration, reshaping rather than eliminating roles. This perspective sparks debate on the ethical implications of widespread automation adoption. A common tip from industry insights is for businesses in high-demand regions to explore robotics integration, focusing on technologies that complement human workers. Such an approach is often recommended to maximize efficiency while maintaining a balanced workforce dynamic.

Creating Interconnected Industrial Ecosystems for Greater Impact

The concept of interconnected ecosystems dominates discussions on how partnerships amplify innovation and efficiency. Many industry observers draw comparisons between sustainability-focused efforts, startup support, and automation initiatives, noting their combined potential to transform entire sectors. The long-term value of these collaborative models is widely acknowledged as a driver for sustained progress.

Contrasting viewpoints emerge on how these ecosystems might evolve, with some predicting rapid integration across global markets, while others warn of unforeseen challenges like regulatory hurdles. Speculation on adapting to global crises over the next decade, from 2025 to 2035, often adds depth to these conversations, revealing varied expectations. A shared piece of advice is for companies to prioritize interoperability within their partnerships, ensuring that solutions can seamlessly integrate across industries. This focus on connectivity is seen as crucial for maximizing the impact of collaborative efforts.

Key Takeaways From Industry Voices

Reflecting on the insights gathered, it’s clear that partnerships in 2025 have paved the way for remarkable strides in sustainability and automation. From reducing waste through innovative inventory practices to empowering startups with critical resources, and automating high-demand sectors with advanced robotics, these alliances demonstrate the power of collective action. Differing opinions on scalability, ethical considerations, and resource distribution add nuance to the conversation, enriching the understanding of these complex initiatives. Looking ahead, companies are encouraged to adopt actionable strategies inspired by these collaborations, such as implementing redistribution models for surplus goods or investing in startup ecosystems to drive innovation. Integrating robotics with a focus on human collaboration emerges as a practical step for operational efficiency. For those eager to stay competitive, aligning with sustainability and innovation goals through strategic alliances becomes a recommended path, ensuring resilience in an ever-evolving industrial landscape.