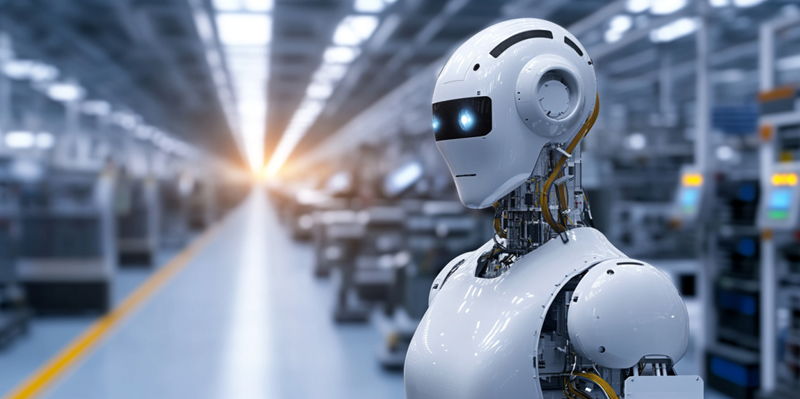

The rapid advancements in artificial intelligence (AI) and robotics are reshaping the landscape of manufacturing in unprecedented ways, introducing innovations that promise to revolutionize traditional processes and systems. Among the most notable developments in this arena is the introduction of AI-powered controllers, which offer enhanced decision-making capabilities and could significantly impact manufacturing efficiency and flexibility. One such innovation making waves is Vention’s MachineMotion AI controller. This advanced technology marks a significant shift from traditional programmable logic controllers (PLCs) and brings a new level of sophistication to industrial automation. With its ability to process vast amounts of data and respond dynamically, MachineMotion AI is poised to change how robots are integrated and utilized in manufacturing settings, offering unprecedented levels of adaptability and performance.

The Evolution from PLCs to AI-Powered Controllers

Traditional programmable logic controllers (PLCs) have long been the backbone of manufacturing automation, providing reliable control of machinery through ladder logic diagrams and predefined decision-making rules. While these systems have been effective in many applications, they often struggle to adapt to complex and dynamic manufacturing environments that require real-time responsiveness. This limitation has created a significant gap, which AI-powered controllers like Vention’s MachineMotion AI are now bridging. Unlike their PLC counterparts, AI-powered controllers are designed to handle the complexities and nuances of modern manufacturing processes.

AI-powered controllers can process vast amounts of data from multiple sources, including sensors and historical performance records. This data-driven approach allows for more nuanced and adaptive decision-making processes, enabling the system to respond to changes and unforeseen challenges in real time. The shift from traditional PLCs to AI controllers signifies a move towards more sophisticated automation systems that can handle intricate tasks with greater precision and reliability. As these technologies continue to evolve, they are expected to become an integral part of advanced manufacturing operations, offering enhanced capabilities that go beyond the limitations of conventional automation solutions.

Key Features and Capabilities of MachineMotion AI

The MachineMotion AI controller is designed to cater to the diverse needs of the modern manufacturing industry, offering a range of advanced features that surpass the capabilities of traditional PLC systems. One of the standout features of MachineMotion AI is its advanced computing operations. Leveraging cutting-edge AI technologies, the controller can autonomously execute complicated decision-making processes, making it a game-changer in the realm of automated manufacturing. This capability allows for greater autonomy and efficiency in robotic operations, reducing the need for constant human intervention and oversight.

Another critical aspect of MachineMotion AI is its robust compatibility and power. The controller supports a variety of popular robot brands, including FANUC, Universal Robots, and ABB, making it a highly versatile option for manufacturers who operate different robotic systems. This compatibility ensures that MachineMotion AI can be seamlessly integrated into existing manufacturing setups, providing a flexible and future-proof solution. Additionally, the controller can control up to 30 servo motors via EtherCAT and deliver up to 3,000 W of power, ensuring it can handle even the most demanding industrial applications. This high level of performance and versatility makes MachineMotion AI a valuable asset for manufacturers looking to enhance their automation capabilities.

Vention’s Manufacturing Automation Platform

Integral to the successful deployment of the MachineMotion AI controller within manufacturing environments is Vention’s Manufacturing Automation Platform (MAP). This comprehensive web-based platform supports the entire automation lifecycle, from design and simulation to programming and monitoring, providing manufacturers with a seamless and integrated environment for managing their automation projects. MAP includes a suite of tools specifically designed to streamline the automation process and enhance the capabilities of MachineMotion AI.

One of the key components of MAP is MachineBuilder, an intuitive design module that allows users to create customized factory floor layouts by selecting appropriate components for their specific manufacturing needs. This tool simplifies the design process and helps ensure that all necessary elements are properly integrated into the overall automation system. Another critical tool within MAP is MachineLogic, an environment that provides advanced programming and simulation capabilities. MachineLogic allows users to simulate robotic interactions and processes in a virtual setting before actual deployment, reducing the risk of errors and improving overall efficiency. Rounding out the suite is MachineAnalytics, a powerful data analysis tool that helps optimize robotic motions, enhance safety protocols, and boost operational efficiency by providing valuable insights into the performance of the automation system.

Collaborative Efforts with ABB

The collaboration between Vention and ABB represents a significant milestone in the evolution of manufacturing robotics, bringing together two industry leaders to create a more integrated and efficient automation ecosystem. ABB’s GoFa cobots are renowned for their collaborative capabilities, designed to work alongside humans in tasks such as welding, assembly, and inspection. These cobots are engineered to be user-friendly and adaptable, making them an ideal complement to Vention’s AI-powered automation solutions. Through this partnership, Vention’s MAP seamlessly integrates with ABB’s cobots, providing enhanced functionality and streamlined deployment.

This collaboration simplifies the process for manufacturers to prototype and implement cobot manufacturing cells, enabling them to move more efficiently from initial design through to full production. The interoperability between Vention’s AI-powered controllers and ABB’s collaborative robots reduces the barriers to adoption, making advanced robotics more accessible to a broader range of manufacturers. By leveraging the strengths of both companies, this partnership ensures that manufacturers can take full advantage of the latest advancements in robotics and AI, leading to improved productivity and operational efficiency in their manufacturing workflows.

The Broader Impact on Manufacturing

The introduction of AI-powered controllers like MachineMotion AI and the enhanced collaboration between Vention and ABB mark a significant shift towards smarter, more adaptable manufacturing solutions. These innovations promise to transform the manufacturing industry by enhancing flexibility and efficiency in production processes, allowing for real-time decision-making and adjustments based on complex data inputs. The ability to process and act upon vast amounts of data enables AI-powered controllers to optimize operations in ways that traditional PLCs cannot, leading to improved performance and reduced downtime.

Moreover, the increased accessibility of these advanced systems lowers the entry barrier for manufacturers, particularly small and medium-sized enterprises that may have previously found such technology cost-prohibitive or too complex to implement. The scalability of systems like MachineMotion AI, which can support high power outputs and numerous servo motors, ensures they can meet the varying needs of different manufacturing setups. This adaptability makes it easier for manufacturers to adopt and benefit from advanced automation technologies, driving innovation and competitiveness across the industry.