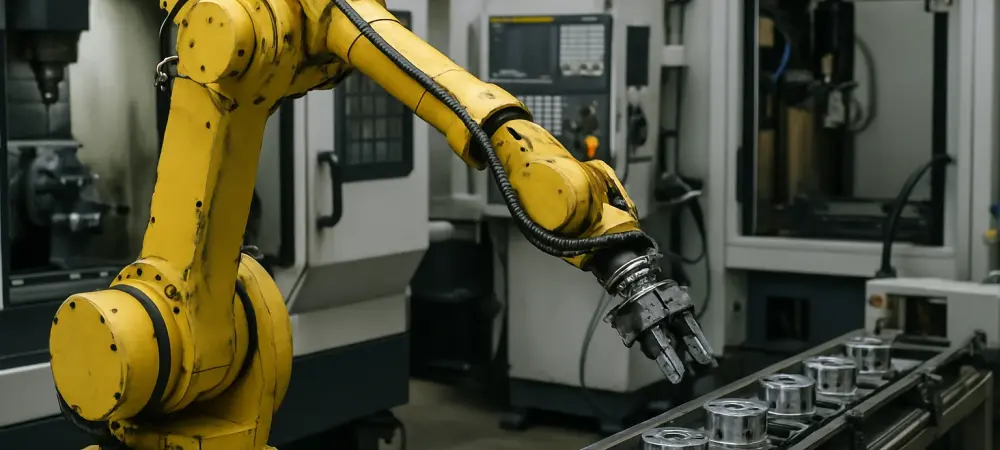

In a world where industrial efficiency can make or break a company, imagine a factory floor where every second of downtime costs thousands of dollars, and the smallest error halts production, driving the relentless push for smarter, tougher automation solutions. This high-stakes reality fuels the need for innovation, and at the forefront of this revolution stands Banner Engineering, a company crafting tools that not only meet today’s demands but also anticipate tomorrow’s challenges. With cutting-edge products transforming how industries operate, their innovations are setting a new benchmark for what automation can achieve.

The significance of this story lies in the urgent need for industries to adapt to an ever-changing landscape. From manufacturing to logistics, businesses face mounting pressures to enhance safety, reduce costs, and boost productivity under increasingly harsh conditions. Banner Engineering’s latest advancements tackle these issues head-on, offering practical solutions that resonate with the broader trend of digital integration and mobile automation. This narrative explores how their technology is reshaping industrial processes, ensuring companies stay competitive in a fast-paced market.

What Fuels the Evolution of Industrial Automation?

Industrial automation is undergoing a profound shift, driven by the need for precision and resilience in environments where failure is not an option. Factories and warehouses must navigate tighter deadlines, complex human-machine interactions, and unforgiving conditions like extreme temperatures or constant vibration. The demand for seamless connectivity and real-time data has never been higher, especially as the Internet of Things (IoT) becomes a cornerstone of modern operations.

Banner Engineering emerges as a key player in this transformation, delivering tools that address these exact pain points. Their focus on rugged design and intuitive functionality ensures that industries can push efficiency boundaries without sacrificing reliability. By aligning with trends such as smart manufacturing and mobile equipment automation, their solutions pave the way for a more connected and adaptable industrial ecosystem.

Why Automation Breakthroughs Are Critical Today

The stakes in industrial automation have soared, with downtime often costing businesses thousands per minute. A single glitch in a production line or a safety oversight in a warehouse can lead to cascading losses. This reality underscores the pressing need for technology that not only keeps pace with current demands but also anticipates future hurdles, ensuring operations remain smooth and secure.

Beyond financial impacts, the push for safer and smarter workplaces adds another layer of urgency. Industries are under pressure to integrate systems that enhance operator interaction while withstanding harsh settings. Banner Engineering’s innovations stand out by offering robust answers to these challenges, prioritizing durability and ease of use to help companies meet stringent safety standards and operational goals.

Unveiling Banner Engineering’s Cutting-Edge Solutions

Banner Engineering has rolled out a trio of groundbreaking products, each designed to solve distinct automation challenges with precision. The K50 I/O Touch Control with Display redefines operator interaction, especially in tasks like bin picking. Featuring dual capacitive touch zones that work even through gloves, paired with a 14-segment display and LED animations for status updates, this device cuts out mechanical wear and supports versatile outputs for speed control without needing a PLC.

Next, the M12 D-Code to RJ45 Connector tackles the issue of reliable Ethernet connectivity in tough industrial environments. Built to handle vibration, dust, and moisture, it simplifies transitions from external M12 cables to internal standard setups. This innovation streamlines panel building, saves critical time, and minimizes wiring errors, proving indispensable for maintaining network integrity in demanding conditions.

Lastly, the Q90R2 77 GHz Radar Sensor brings unmatched detection capabilities to mobile equipment like AGVs and forklifts. Operating at a high frequency, it excels in outdoor settings, penetrating rain or snow to monitor two zones for distance, position, and speed. With IP67/IP69K ratings and easy configuration via Banner’s software, it enhances safety and efficiency in dynamic spaces like loading bays, showcasing a blend of advanced tech and practical application.

Real-World Impact: Voices from the Industry

Feedback from those on the front lines highlights the tangible difference Banner Engineering’s tools make. An automation specialist recently noted, “The K50 Touch Control’s glove-friendly design and customizable display have reduced operator errors in our plant by 30%, streamlining daily tasks.” Such insights reveal how intuitive design translates to measurable gains in productivity.

In another instance, a major warehouse reported significant safety improvements after deploying the Q90R2 Radar Sensor on their AGVs. The sensor’s ability to detect obstacles in adverse weather slashed collision risks, protecting both equipment and personnel. These accounts, combined with Banner’s emphasis on user-friendly features like IO-Link integration, paint a clear picture of technology that delivers real results in challenging environments.

Transforming Operations with Banner’s Innovations

For businesses looking to elevate their automation game, Banner Engineering’s products offer actionable pathways to success. Start by integrating the K50 I/O Touch Control into assembly or picking stations. Using Banner’s free Pro Editor software, customize displays for timers or alerts to sharpen workflow clarity and cut training time, directly boosting operator efficiency.

To ensure robust network performance, consider the M12 D-Code to RJ45 Connector for setups exposed to harsh conditions. Proper installation outside electrical cabinets shields against dust and vibration, maintaining uninterrupted data flow. This small but critical step can prevent costly network failures and keep operations running smoothly.

For mobile equipment safety, equipping AGVs or forklifts with the Q90R2 Radar Sensor proves transformative. Configure dual-zone monitoring through Banner’s Measurement Sensor software to spot obstacles over long distances, even in rain or snow. This approach minimizes downtime and accidents, offering a strategic edge in fast-moving, high-risk environments.

Reflecting on a Legacy of Innovation

Looking back, Banner Engineering has carved a remarkable path in industrial automation by delivering solutions that balance sophistication with practicality. Their trio of products—the K50 Touch Control, M12 Connector, and Q90R2 Radar Sensor—has addressed diverse needs, from operator precision to environmental resilience, proving their foresight in a competitive field.

As industries continue to evolve, the challenge remains to stay ahead of emerging demands. Businesses are encouraged to explore how such technologies can be tailored to their unique setups, prioritizing adaptability to future-proof operations. Engaging with experts or testing these tools in pilot projects offers a practical next step, ensuring that automation strategies grow stronger and more responsive to an ever-shifting landscape.