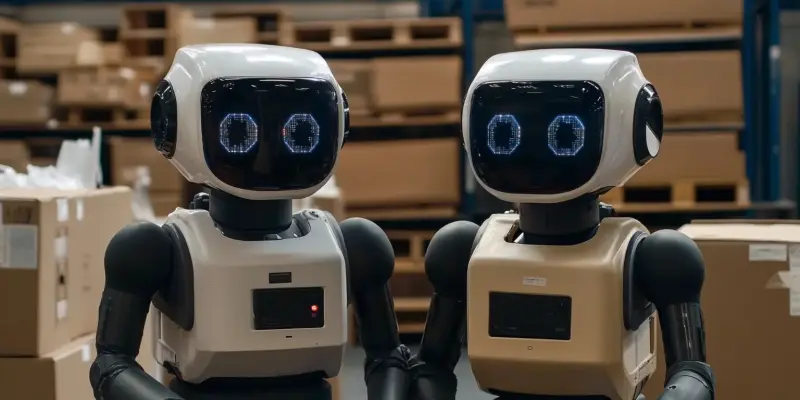

The collaboration between Apptronik, a leader in humanoid robot technology, and Jabil, a manufacturing and supply chain technology provider, promises a transformative shift in how robots are manufactured and integrated into production environments. This partnership aims to revolutionize manufacturing by integrating Apptronik’s Apollo humanoid robots into Jabil’s advanced production lines. The goal is to achieve an efficient and scalable manufacturing process for humanoid robots, opening new avenues for their application in various industries.

Transforming Manufacturing with Humanoid Robots

Apollo Building Apollo

Apptronik’s vision of “Apollo building Apollo” signifies a groundbreaking approach where humanoid robots will be used to build other humanoid robots, creating a self-sustaining production cycle. This concept has the potential to revolutionize manufacturing by making the production process faster, more scalable, and cost-effective. By leveraging Jabil’s expertise in advanced automation and robotics, Apptronik aims to validate and refine this innovative approach in a real-world manufacturing environment.

According to Apptronik CEO Jeff Cardenas, the potential of humanoid robots to transform daily life and work hinges on their efficient and scalable manufacturing. The collaboration with Jabil is specifically designed to support this vision. Jabil’s extensive experience in automation and robotics provides an ideal platform for testing and deploying Apollo robots. By integrating these robots into their material movement and assembly tasks, Jabil is effectively creating a dynamic feedback loop that will accelerate the deployment and widespread use of humanoid robots. This initiative is not just about improving manufacturing processes; it is about setting the stage for a future where humanoid robots play an integral role in various industrial and commercial applications.

Real-World Testing and Deployment

One of the significant aspects of this partnership is the real-world testing and deployment of Apollo robots within Jabil’s operations. These robots will perform a range of repetitive and labor-intensive tasks such as inspection, sorting, kitting, lineside delivery, fixture placement, and sub-assembly. By taking over these monotonous tasks, Apollo robots will free up human workers to focus on more creative and strategic activities. This not only enhances efficiency but also improves job satisfaction and productivity among workers.

In Jabil’s high-paced manufacturing environments, the Apollo robots will undergo rigorous testing to ensure they meet the required performance standards. These robots are designed to be versatile and adaptable, capable of performing a wide variety of tasks with precision and efficiency. The data collected from these real-world deployments will be invaluable in refining the robots’ capabilities and ensuring they can seamlessly integrate into different manufacturing processes. By continuously improving the robots based on real-world performance data, Apptronik aims to create a product that is both reliable and highly effective in meeting the needs of modern manufacturing.

Strategic Partnerships and Financial Boost

A Financial Milestone

Apptronik’s recent achievement of raising $350 million in funding marks a significant milestone in their journey towards revolutionizing manufacturing with humanoid robots. This substantial financial boost is aimed at accelerating the deployment and scaling of Apollo robots. The funds will support various aspects of the company’s operations, from enhancing their technological capabilities to expanding their team to meet the growing demand for AI-powered humanoid robots. This financial injection will also drive innovation, enabling Apptronik to continue pushing the boundaries of what is possible with humanoid robotics.

The financial investment will also support Apptronik’s ongoing research and development efforts. By investing in cutting-edge technologies and expanding their team of experts, the company is well-positioned to address the growing demand for advanced robotic solutions. This funding is a testament to the confidence investors have in Apptronik’s vision and their ability to lead the future of humanoid robotics. With this financial backing, Apptronik is poised to make significant strides in transforming how robots are manufactured and deployed across various industries.

Expanding Strategic Collaborations

Apptronik’s strategy to revolutionize manufacturing with humanoid robots involves establishing robust partnerships with industry leaders. The company’s collaboration with NASA aims to commercialize Apollo robots, bringing them into the mainstream market. Similarly, their partnership with Mercedes-Benz is focused on deploying Apollo robots in labor-intensive factory tasks, showcasing the versatility and potential of these robots in enhancing operational efficiency. These strategic collaborations are crucial in demonstrating the real-world applications and benefits of humanoid robots.

Additionally, Apptronik has teamed up with GXO to automate warehouse operations, further expanding the scope of Apollo robots in industrial applications. The company’s collaboration with Nvidia on integrating Apollo into Omniverse digital twins represents another innovative step towards creating more interconnected and intelligent manufacturing systems. Furthermore, Apptronik is working with Google DeepMind’s robotics team to explore new possibilities in AI and machine learning for robotics. Each of these partnerships brings unique expertise and resources, collectively advancing the development and deployment of Apollo robots in diverse settings.

Redefining Manufacturing and Supply Chain Operations

Addressing Labor Shortages

One of the pressing challenges in the manufacturing industry is the ongoing labor shortage. Apptronik’s advanced humanoid robots offer a viable solution to this problem by automating repetitive and labor-intensive tasks. These robots are designed to work alongside human workers, augmenting their capabilities and improving overall productivity. By addressing the labor shortage, Apollo robots can help manufacturers meet increasing production demands and maintain high levels of efficiency.

Apptronik’s vision is to create a more collaborative and efficient manufacturing environment where humans and robots work together seamlessly. The Apollo robots are equipped with advanced AI and machine learning capabilities, enabling them to learn and adapt to different tasks quickly. This flexibility makes them an invaluable asset in any manufacturing setting, as they can be easily reprogrammed to perform a variety of tasks as needed. By leveraging the strengths of both human workers and robots, manufacturers can achieve higher levels of productivity and quality.

Future Considerations and Next Steps

The partnership between Apptronik, a key player in humanoid robot technology, and Jabil, a renowned manufacturing and supply chain technology provider, signifies a significant shift in how robots are made and utilized in production settings. This collaboration aims to bring about a revolutionary change in manufacturing processes by integrating Apptronik’s Apollo humanoid robots into Jabil’s state-of-the-art production lines. The primary objective is to streamline and scale the manufacturing process for humanoid robots, thereby paving the way for their broader adoption across numerous industries. By joining forces, Apptronik and Jabil are poised to enhance efficiency and scalability in robot production, fundamentally changing the manufacturing landscape. This partnership could lead to expanded capabilities and applications for humanoid robots, potentially setting new standards in industrial automation and other sectors. Through this innovative synergy, the companies aspire to set a precedent for the future of robotics in manufacturing and various other fields, enabling more widespread and advanced use of humanoid robots.