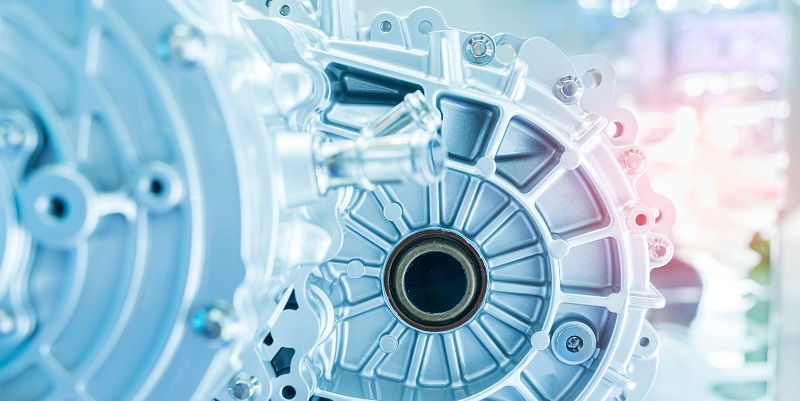

Electric motors play a crucial role in the automotive industry’s decarbonization efforts, ensuring sustainability and driving performance. As the demand for electric vehicles continues to rise, manufacturers face the challenge of maintaining the highest quality standards for motor components. To address this need, CAPTURE 3D, a ZEISS company, has unveiled the ZEISS ScanBox for eMotors, an automated 3D scanning solution designed specifically for inspecting electric motor hairpin-stator assemblies.

Overview of ZEISS ScanBox for eMotors

The ZEISS ScanBox for eMotors leverages the advanced capabilities of the ZEISS ATOS Q-EV blue light 3D scanning sensor. With lightning-fast speed, this solution captures high-resolution 3D measurement data from electric motor assemblies. This automated process eliminates human error and significantly reduces inspection time, enabling manufacturers to streamline their operations and enhance productivity.

The significance of inspecting hairpin-stator assemblies

When it comes to electric motor production, ensuring the quality of hairpin-stator assemblies is paramount. These assemblies have a direct impact on the overall performance and sustainability of electric vehicles. By accurately inspecting hairpin-stator assemblies, manufacturers can identify potential issues early on and ensure optimal functioning, efficiency, and longevity of the motor.

Challenges in Inspecting Hairpin-Stator Assemblies

Inspecting hairpin-stator assemblies poses unique challenges. These complex components require precise measurement data for alignment, geometric dimensioning and tolerancing (GD&T), crown, twist, and radial analysis. Traditional inspection methods often fall short in capturing intricate details accurately. This is where the ZEISS ScanBox for eMotors steps in to provide a reliable and efficient solution.

Features and capabilities of ZEISS ScanBox for eMotors

The ZEISS ScanBox for eMotors overcomes the limitations of conventional inspection approaches. By capturing accurate measurement data, this solution enables manufacturers to perform comprehensive inspections, ensuring that all quality requirements are met. The ZEISS Quality Suite software operates the ScanBox, with the Virtual Measuring Room (VMR) simulating the measuring environment and enhancing measurement precision.

Smart Teach function in the VMR

To further enhance measurement repeatability, the ZEISS ScanBox for eMotors incorporates the Smart Teach function within the VMR. This innovative feature enables the system to determine the optimal sensor positions for measurements automatically. By eliminating guesswork, manufacturers can achieve consistent and reliable results for every inspection.

Generation of a Complete Geometric Digital Twin

With millions of coordinates collected during the scanning process, the ZEISS ScanBox for eMotors generates a complete geometric digital twin of the hairpin-stator assembly. This digital twin serves as a reference for comparing nominal and actual dimensions. Manufacturers gain valuable insights into deviations, defects, and process stability, allowing for timely corrective actions and continuous improvement.

Inspection tasks supported by ZEISS ScanBox for eMotors include

The ZEISS ScanBox for eMotors supports both simple and complex inspection tasks for hairpin and stator components. From evaluating form, angle, and positional tolerances to detecting cracking, deformation, and fitting accuracy, this innovative solution ensures comprehensive quality assurance and adherence to strict industry standards.

Digital assembly using captured data

Another significant advantage of the ZEISS ScanBox for eMotors is the ability to digitally assemble the stator and rotor components. Manufacturers can utilize the captured data to accurately simulate the assembly process, ensuring a perfect fit between the components. This precise digital assembly eliminates errors and reduces production time while ensuring the highest level of quality.

With the introduction of the ZEISS ScanBox for eMotors, manufacturers in the automotive industry have a game-changing solution for inspecting electric motor hairpin-stator assemblies. This automated 3D scanning solution offers unparalleled speed, accuracy, and efficiency, enabling manufacturers to achieve exceptional results in quality assurance. By harnessing the power of the ZEISS ScanBox for eMotors, the industry can drive sustainability, performance, and innovation in the world of electric vehicles.