Dominic Jainy is a distinguished IT professional renowned for his vast knowledge of artificial intelligence, machine learning, and blockchain technology. With a keen interest in applying these cutting-edge technologies across various sectors, Dominic joins us today to delve into the promising intersection of autonomous vehicles and construction technology.

Can you share the inspiration behind starting Bedrock Robotics and how your experience at Waymo influenced your decision to focus on autonomous construction equipment?

The idea to start Bedrock Robotics emerged from my time at Waymo, where I witnessed firsthand the transformative power of autonomous technology. Working on self-driving vehicles highlighted the potential for automation beyond transportation. The construction industry, much like transportation, is ripe for innovation. The repetitive and demanding nature of construction tasks makes them ideal candidates for autonomy. My experience at Waymo taught me that if we can navigate the complexities of autonomous driving, we can certainly adapt similar technologies to revolutionize how heavy construction equipment operates, especially in environments where human endurance is tested.

How did you assemble the founding team for Bedrock Robotics, and what key skills do each of the founding members bring to the company?

Assembling the founding team was a strategic process. Having collaborated with Ajay Gummalla and Kevin Peterson at Waymo, I knew the depth of their technical skills and their innovative thinking. Tom Eliaz brought in a fresh perspective with his engineering expertise. Our combined experiences cover a broad spectrum—from mechanical engineering to AI software development—which is crucial for tackling the multifaceted challenges in autonomous construction equipment. Our COO, Laurent Hautefeuille, formerly of Uber Freight, introduced operational expertise critical for scaling our vision.

What specific challenges have you faced in modifying existing construction equipment for autonomous operation, and how have you addressed these challenges?

Modifying existing construction equipment for autonomy presents a unique set of challenges. These machines were not initially designed for autonomous operation, so integrating sensors, such as lidar and cameras, requires significant retrofits. One of our main challenges is ensuring this technology can withstand harsh construction site environments. We’ve tackled these issues by developing robust hardware solutions and advanced AI software to ensure reliability and precision.

Given the current labor shortage in the construction industry, how do you see Bedrock Robotics’ technology impacting job roles for human workers on construction sites?

In the context of the current labor shortage, our technology is designed to complement rather than replace human workers. By automating the more repetitive and physically demanding tasks, we free up human operators to focus on more skilled and strategic aspects of construction projects. This technology not only enhances productivity but also creates safer and more manageable work conditions. As a result, human roles on construction sites will evolve, requiring upskilling to work in tandem with advanced machinery.

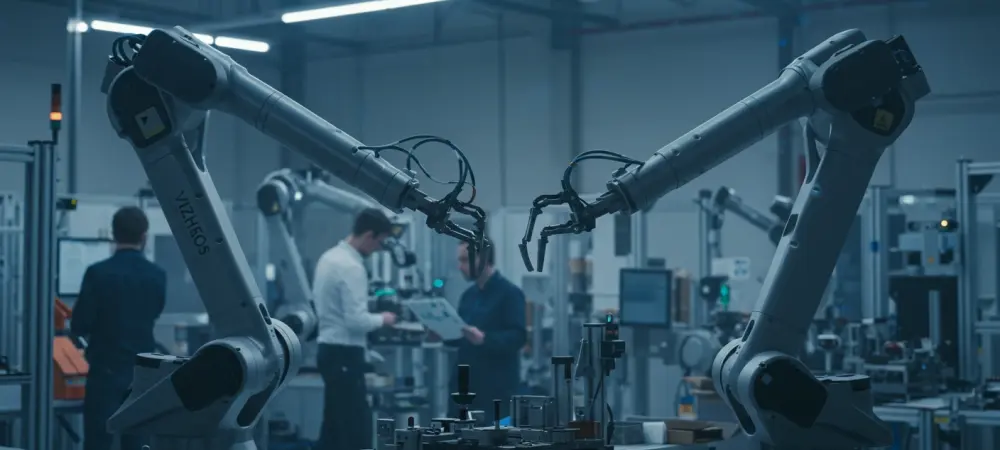

What are the key technological components, such as cameras, lidar, and AI software, that are essential to Bedrock Robotics’ autonomous systems?

The backbone of our autonomous systems includes a combination of high-resolution cameras, precision lidar sensors, and sophisticated AI software. Cameras provide real-time imaging, lidar offers depth perception, and our AI software processes these inputs to make informed decisions that guide the machinery. This integration allows the equipment to navigate, understand its environment, and perform tasks with incredible accuracy, transforming standard machinery into intelligent, autonomous units.

Can you explain how laser lidar technology is used in Bedrock Robotics’ system to measure the amount of dirt moved during excavation?

Laser lidar technology plays a pivotal role in our systems by allowing precise mapping and quantification of excavation work. It generates accurate 3D models of the terrain, enabling us to measure the exact volume of dirt moved with each scoop. This precision is crucial not only for operational efficiency but also for billing and compliance purposes, as it provides real-time data that construction companies can rely on for accurate reporting and planning.

What plans does Bedrock Robotics have for the commercialization of autonomous excavators, and what will the rollout process look like?

Our commercialization strategy is meticulously planned. We are currently in the testing phase at select sites across the U.S. By 2026, we aim to launch the first fully autonomous excavator ready for commercial use. The rollout will involve close collaboration with our partners and training for operators to transition seamlessly to using autonomous technology. We foresee a phased introduction, beginning with private construction sites, to fine-tune our systems and gather valuable user feedback before a broader market release.

Could you elaborate on your partnership strategies with established equipment manufacturers like Caterpillar and Deere?

Our partnership strategy is all about collaboration rather than competition. Established equipment manufacturers like Caterpillar and Deere have an unmatched legacy in creating robust machinery. Our aim is to enhance their existing products with our autonomous technology, making machines smarter and more efficient. Partnering with these industry leaders allows us to leverage their manufacturing capabilities while we contribute our AI expertise to push the construction industry towards a more automated future.

What cost savings or productivity improvements can construction companies expect from employing Bedrock Robotics’ autonomous technologies?

Employing our autonomous technology can lead to significant cost savings and productivity improvements. We estimate that projects can benefit from at least a 20% reduction in operational costs, primarily through enhanced efficiency and reduced downtime. The ability to operate around the clock without the constraints of human endurance means projects can advance quicker, likely reducing timelines and associated financial overheads. This optimization allows construction companies to allocate resources more effectively and increase their overall profitability.

What factors have contributed to Bedrock Robotics’ rapid progress from concept to testing and commercialization?

A combination of factors has bolstered our rapid progress. The team’s strong technical foundation and our experience with autonomous systems have certainly accelerated development. Additionally, strategic partnerships and substantial funding have provided us with the resources necessary to devise quick yet effective solutions. Market demand for innovation in construction and the clear benefits of automation have also driven us to swiftly convert our concepts into tangible, testable prototypes.

How do regulatory challenges differ between operating autonomous machinery on private construction sites versus public roadways?

Operating on private construction sites presents significantly fewer regulatory hurdles compared to public roadways. Private sites allow us more control over the environment and minimize the complexities associated with public traffic laws and safety standards. This controlled setting accelerates testing and development. However, we still adhere to safety and operational protocols to ensure that our autonomous machinery functions reliably and meets all necessary safety regulations.

How is Bedrock Robotics planning to tackle the potential challenges related to upfitting complex existing machinery with autonomous capabilities?

Upfitting existing machinery involves overcoming mechanical and technological integration challenges. Our approach includes developing adaptable hardware modules that can be fitted onto a wide range of machinery types. We focus on standardizing key components like sensors and processors to ensure compatibility and ease of maintenance. Collaborating closely with industry experts and machinery operators, we aim to streamline the integration process while ensuring that the modifications enhance the capabilities of existing machines.

What are your expectations for Bedrock Robotics in terms of further fundraising and valuation over the coming year?

As we continue to progress with testing and move closer to commercialization, we anticipate needing additional rounds of funding to support our scaling efforts. While we have not disclosed specific financial targets, the positive feedback from our testing phases suggests strong investor confidence. We expect subsequent fundraising initiatives to enhance our valuation significantly, allowing us to expand operations and accelerate our entry into the market.

Could you briefly describe the feedback you’ve received from early testing partners such as Sundt Construction and Zachry Construction? How has it shaped your development plans?

Feedback from Sundt Construction and Zachry Construction has been invaluable. They have noted the efficiency and precision of our systems in handling repetitive tasks and operating in diverse environments. Their input has led us to prioritize adaptability and ease of integration in our development plans, ensuring our technology seamlessly fits into existing workflows. This collaboration promises to refine our technology further, aligning it more closely with industry needs and real-world scenarios.

What do you envision for the future of construction technology, particularly in terms of automation and its impact on the industry as a whole?

The future of construction technology is undeniably leaning towards increased automation. I foresee an industry where automation is integral to every stage of a project, from planning to execution. This shift will not only speed up construction processes but also lead to a safer, more efficient, and more sustainable industry. As machinery becomes more intelligent, we will see a change in the workforce dynamics, with new roles emerging and an increased emphasis on technical skills to manage and maintain these advanced systems. Overall, the impact will be transformative, potentially reshaping economies by making infrastructure development quicker and more accessible.

Are there any specific lessons learned from autonomous vehicle technology that you are applying to autonomous construction machinery?

Absolutely. One significant lesson from autonomous vehicle technology is the importance of robust sensor fusion systems—integrating data from multiple sensors to make informed decisions in real-time. We’ve adapted this principle to create autonomous construction machinery that can accurately assess and adapt to changing site conditions. Additionally, the emphasis on rigorous safety protocols and continuous testing found in automotive autonomy is directly applicable to our construction machinery, ensuring that our technology meets high safety standards right from the outset.

How do you ensure the adaptability of your autonomous technology across various types and models of construction equipment?

We ensure adaptability by designing flexible hardware and software solutions. Our technologies are modular, allowing us to tailor them to different machinery models while maintaining core autonomous functions. We’ve developed universal interfaces that facilitate easy installation and integration. Collaboration with different manufacturers and operators also allows us to gather insights, ensuring our solutions are both practical and versatile across a range of equipment.

What insights can you share about Bedrock Robotics’ plans for customer site testing next month?

Next month marks a significant step as we transition from controlled test sites to real-world customer locations. This initiative aims to validate our autonomous systems in active construction environments, gather user feedback, and assess our technology’s impact on actual project workflows. Our partner sites have been chosen for their varied conditions, providing us with a comprehensive understanding of our technology’s performance and scalability. These insights will help fine-tune our systems, ensuring a robust and market-ready product.

What role do venture capital firms and funding partners play in Bedrock Robotics’ ongoing development and expansion efforts?

Venture capital firms and funding partners have played a critical role in our development and expansion. They provide not only the necessary capital to advance research and refine our technology but also valuable industry connections and strategic guidance. Their support accelerates our path to commercialization, allowing us to access resources and opportunities that propel our growth. Their partnership is essential in transforming our vision into tangible advancements in construction technology.

Do you have any advice for our readers?

For those interested in the intersection of technology and industry, it’s crucial to stay curious and open to learning about emerging technologies. Autonomous systems are reshaping numerous fields, including construction, offering both challenges and opportunities. Embrace the change by upskilling and understanding the technology’s impact on your industry. Collaboration and innovation are key, so engage with others in the field, share knowledge, and contribute to shaping a future where technology enhances productivity and sustainability.