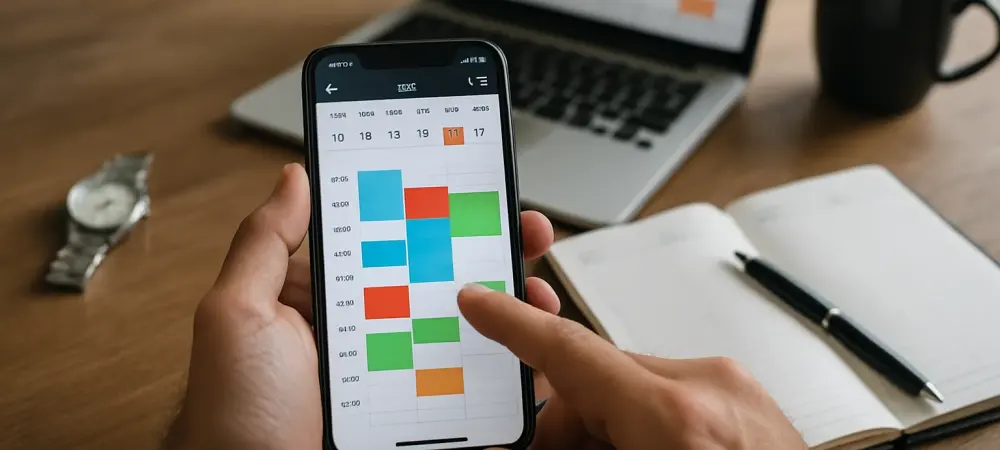

The familiar sight of a production manager frantically rearranging a digital Gantt chart is a clear signal that a manufacturing operation has outgrown its foundational tools. This manual, reactive approach to managing shop floor complexity is a bottleneck that stifles growth and invites chaos. In today’s high-mix, fast-paced production environments, the shift from manual drag-and-drop planning to automated, rule-based scheduling is no longer a competitive advantage but a fundamental necessity for survival. This analysis deconstructs the inherent flaws of traditional methods, explores the core capabilities driving the trend toward advanced scheduling systems within ERP platforms like Microsoft Dynamics 365 Business Central, and projects the future of this transformative, data-driven paradigm.

The Emerging Standard Automation in Production Planning

The Inadequacy of Legacy Scheduling Methods

The fundamental flaw of traditional visual scheduling lies in its design; it is a relic of a simpler manufacturing era, unsuited for the modern complexities of high-mix production, intricate multi-stage processes, and ever-tightening lead times. While intuitive at a small scale, the drag-and-drop interface becomes a significant liability as operational volume and variability increase. This method forces planners to make critical decisions based on an incomplete picture, often leading to suboptimal sequencing, unforeseen bottlenecks, and missed deadlines. This reliance on manual intervention institutionalizes “tribal knowledge,” where the entire production plan’s viability rests on the experience and intuition of a single human scheduler. This creates an enormous business risk and a single point of failure. When that key individual is overworked, absent, or leaves the company, their nuanced understanding of shop floor dynamics is lost, resulting in inconsistent decision-making, excessive administrative overhead, and an operational fragility that modern businesses cannot afford.

Real-World Application Automated Scheduling in Dynamics 365

The practical application of this trend is evident in the deep integration of advanced scheduling solutions directly into ERP systems like Microsoft Dynamics 365 Business Central. Platforms such as Insight Works’ MxAPS exemplify this shift by embedding sophisticated scheduling logic within the system that manufacturers already use to manage their core business processes, creating a single source of truth. These systems operate by translating a scheduler’s expert knowledge into a configurable, logical rules engine. Instead of relying on memory and guesswork, the software evaluates every production order against a matrix of real-world constraints, including machine capacity, material availability, labor skills, and tooling requirements. The result is a consistently optimized and resilient schedule that reflects the genuine capabilities of the factory floor, not just an idealized plan.

Key Capabilities of Modern Scheduling Systems

Strategic Prioritization Beyond Simple Due Dates

Advanced scheduling systems have moved decisively beyond simplistic, due-date-driven planning. Relying solely on due dates is a flawed strategy, as these dates are often arbitrary targets set without a full understanding of production capacity or strategic business goals. This approach treats all orders as equal, failing to differentiate between a high-value job for a key client and a standard stock order. Modern systems, in contrast, incorporate multi-faceted, business-defined priority logic that allows for automated, strategic decisions. This rules-based engine can be configured to elevate rush orders, promote high-margin jobs to boost profitability, or protect downstream commitments to prevent systemic bottlenecks. The scheduler’s function thus transforms from manual order shuffling to overseeing the strategic rules that govern the automated scheduling process.

Intelligent Grouping for Setup and Changeover Reduction

A core tenet of Lean manufacturing is the relentless pursuit of waste reduction, and setup time remains one of the most significant sources of lost productivity. Manually sequencing hundreds or thousands of operations to minimize changeovers is a monumental task fraught with complexity and human error. An advanced scheduling system tackles this challenge head-on.

The system intelligently groups operations based on shared setup attributes, such as paint color, tooling configurations, or material types. By sequencing jobs with common characteristics to run consecutively, it drastically minimizes machine downtime, maximizes asset uptime, and increases overall plant throughput. This automated optimization ensures that efficiency gains are captured consistently, turning a complex combinatorial problem into a solved operational advantage.

Real-Time Responsiveness and Dynamic Rescheduling

A production schedule is only as valuable as its connection to reality, and the shop floor is an environment of constant change. Machine breakdowns, unexpected material delays, and labor shortages can render a static plan obsolete within minutes. The critical need, therefore, is for a dynamic plan that adapts to these real-world disruptions. By integrating with shop floor data collection systems, an advanced scheduling engine creates a closed-loop feedback system. It automatically consumes real-time information on job completions, unplanned downtime, and resource availability. This allows the system to regenerate schedules at regular intervals, ensuring the plan always reflects the current state of the shop floor. This capability eliminates the chaos of manual overhauls and empowers managers to respond to issues proactively rather than reactively.

The Future Outlook A New Paradigm for Manufacturing

Evolving Roles Balancing Automation with Human Expertise

The rise of automated scheduling heralds a significant evolution in the role of the production planner. The focus shifts from tedious manual data entry and crisis management to the high-level, strategic management of the scheduling rules engine. Human oversight complements automated logic, with schedulers fine-tuning parameters, analyzing performance data, and managing exceptions.

This transition addresses common concerns around user adoption by clarifying that planners retain ultimate control. The system provides the optimal path, but schedulers have the ability to manually override its logic for unique, one-off situations. Such interventions become rare and purposeful strategic decisions rather than the daily norm, empowering planners to apply their expertise where it matters most.

Broader Implications Scalability Resilience and Competitiveness

The long-term benefits of this trend extend far beyond daily efficiency gains. Adopting an automated scheduling system allows manufacturing operations to scale without a corresponding increase in planning personnel, breaking the traditional link between growth and overhead. It also builds a more resilient organization, where operational continuity is maintained during supply chain disruptions or the absence of key employees.

Highly configurable, data-driven scheduling is rapidly becoming the new industry standard. It is no longer an optional upgrade but an essential component for any manufacturer seeking to remain competitive in a complex and demanding global market. The ability to model constraints, optimize flow, and adapt in real time is the defining characteristic of a modern, agile production environment.

Conclusion Embracing Data-Driven Production Flow

The inherent limitations of manual scheduling created a ceiling on manufacturing efficiency and responsiveness that has now been broken. The ascendance of automated, rule-based systems represented a fundamental turning point, driven by core capabilities like strategic prioritization, intelligent setup reduction, and dynamic rescheduling. These pillars transformed production planning from a reactive art into a proactive, data-driven science. For manufacturers operating within ecosystems like Dynamics 365 Business Central, adopting an advanced production scheduling solution was the definitive step toward modernizing operations, building resilience, and cementing a lasting competitive edge in an increasingly complex industrial landscape.