When a single graphics card successfully draws more electrical power than an entire kitchen microwave oven, component failure is no longer a distant possibility but an imminent expectation. This scenario recently became a reality when an enthusiast pushed an unreleased, heavily modified RTX 5090 to a staggering 1350 watts. Yet, the outcome was not the familiar story of a melted 16-pin connector and a catastrophic system failure. Instead, the disaster was narrowly averted by the intelligent design of a single, unassuming power cable.

The New Specter Haunting High-End Gpus

The incident provides a critical look into the future of high-performance computing, where power demands are skyrocketing with each hardware generation. As top-tier graphics cards consume upwards of 600 watts by default, the physical connectors that deliver this energy have become a significant point of failure. This extreme test case, while far beyond typical use, highlights a fundamental challenge for the industry: how to safely manage unprecedented levels of power delivery in consumer-grade hardware. The answer, it appears, may lie not in reinforcing the GPU itself, but in making the components around it smarter.

A Fiery History with Power Connectors

For years, the 12VHPWR 16-pin power connector has been a source of considerable anxiety within the PC building community. Widespread reports and viral images of melted, scorched, and utterly destroyed connectors on high-end GPUs have cultivated a persistent fear around what should be a simple interface. These failures, often attributed to user error, have nonetheless cast a long shadow over the reliability of flagship graphics cards, turning a routine build into a high-stakes endeavor.

This history of hardware destruction provides the essential context for understanding the significance of the recent RTX 5090 event. A system pushed far beyond any reasonable operational limit was ultimately saved not by luck or careful assembly, but by a proactive safety mechanism engineered directly into its power delivery system. It represents a potential turning point from a reactive problem plagued by post-failure analysis to a preventative solution that anticipates and averts disaster.

Anatomy of a Near Disaster

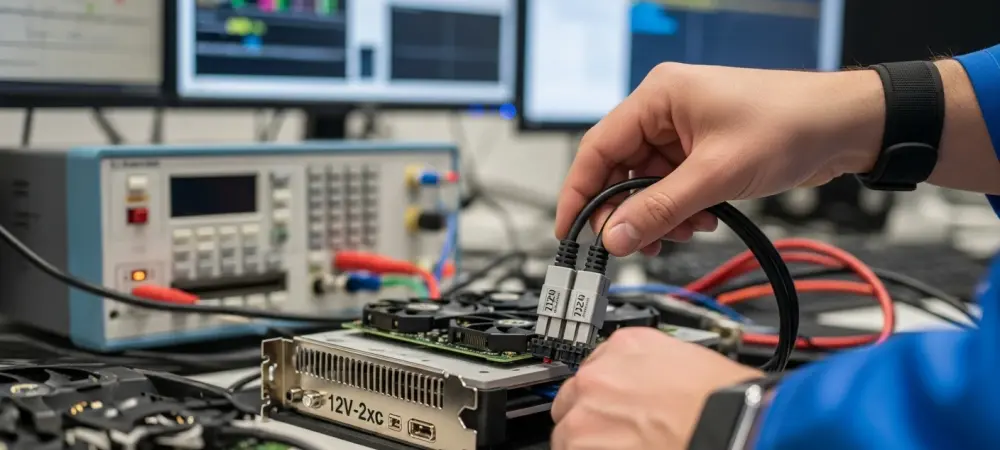

The experiment was a showcase of extreme overclocking. An overclocker known as “Motivman” took a pre-release MSI RTX 5090 Ventus and performed a shunt-mod, a risky hardware alteration that bypasses the manufacturer’s built-in power limits. Paired with a custom liquid-cooling loop to manage the immense heat, the card was subjected to approximately 20 intensive benchmark runs, during which it consistently pulled 1350W—more than double its intended maximum power draw.

Instead of the expected meltdown, the system performed an automatic emergency shutdown. The protective measure was triggered by ASRock’s specialized 12V-2×6 connector cable, which features an integrated Negative Temperature Coefficient (NTC) sensor. This small thermal probe, positioned at the connector head, constantly monitors temperatures and communicates directly with a compatible ASRock power supply. As the connector approached its 105°C thermal threshold, the sensor instructed the PSU to immediately cut power to the GPU, preventing the plastic housing from reaching its melting point.

From the Forums to a Marketing Win

The firsthand account, posted on the Overclock.net forums, painted a vivid picture of the event’s aftermath. “Motivman” praised the technology for saving the expensive hardware, though he noted the extreme heat had left the connector visibly discolored and “irreversibly compromised.” He also provided constructive feedback, suggesting that a more conservative shutdown threshold of 85°C would offer an even greater margin of safety for future revisions of the technology.

ASRock was quick to recognize the marketing potential of this real-world stress test. The company highlighted the user’s story on its official X account, declaring its power supplies “insanely good” for handling the 1350W load without fault while its intelligent cable prevented a component fire. The incident was transformed from a cautionary tale into a powerful testament to the effectiveness and reliability of its engineering.

The Takeaway for PC Builders

This edge-case scenario offers crucial lessons for the broader PC enthusiast community. ASRock’s sensor-equipped cable demonstrates a viable and elegant engineering solution to the connector-melting crisis that has troubled high-end builds. By adding a layer of intelligent thermal monitoring, the system can protect itself proactively, shifting the burden of safety from the user to the hardware itself. This approach stands as a promising blueprint for future industry standards. However, a significant catch tempers this optimism: the system is proprietary. This advanced thermal protection only functions when the specialized ASRock cable is paired with a compatible ASRock Taichi or Phantom Gaming series power supply. This creates a “walled garden” ecosystem, where users must commit to a single brand to benefit from the enhanced safety feature, limiting its widespread adoption for now. Ultimately, this incident serves as a testament to a safety feature, not an endorsement of dangerous modifications. Shunt-modding and other extreme measures void warranties, carry an immense risk of permanent hardware failure, and should not be attempted by anyone but the most experienced overclockers with disposable hardware.