Robots and machines have come a long way in the past decade. There was a time when they couldn’t differentiate between a feather and a brick. However, the intelligent touch sensors have expanded the range of applications in robotics by providing sensitive digital force and displacement measurement. The new technology, DELFA (Dielectric Elastomer Force and Actuation), has made it possible to add a digital sense of touch to the machines, making them more powerful and intelligent.

DELFA Technology

DELFA technology is a highly sensitive, sustainable, and cost-effective solution developed by the Zurich University of Applied Sciences. The material used in DELFA sensors is a dielectric elastomer, which is a highly elastic polymer. The material has excellent mechanical properties, sustainability, and durability, and it is capable of continuously recording and evaluating tensile and compressive forces as well as positions, strains, or motion sequences.

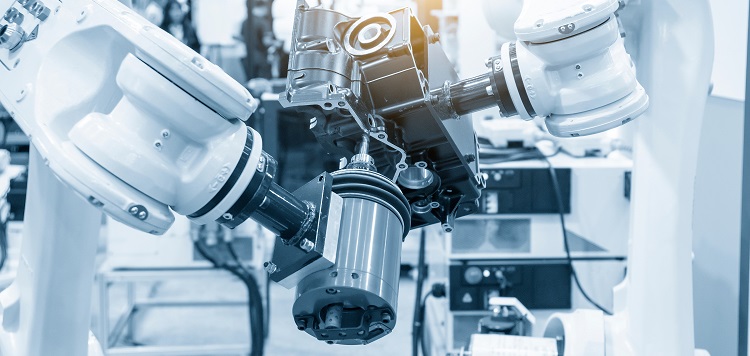

Applications in robotics

These sensors expand the range of applications in robotics by providing sensitive digital force and displacement measurement. They can be added to robot arms, grippers, and end-effectors, allowing robots to perform precise and highly sensitive functions such as assembling, handling, and gripping fragile objects. The sensors can also be used for quality control and product inspection, ensuring the product meets the required standards.

Advantages of sensors

The addition of intelligent touch sensors makes the machines more powerful and efficient. The sensors can detect minute changes in the environment and respond quickly to them. The built-in intelligence of the sensors can significantly increase the process reliability of the handling operation. Moreover, the sensors can detect errors or defects during production, which are impossible for humans to detect. The data from the sensors can be collected and analyzed to improve the manufacturing process.

Bio-inspired gripping technology

A sensitive sensor system has been developed in combination with a bio-inspired gripping technology. The research team at Zurich University of Applied Sciences was inspired by the natural movement patterns of animals such as the human hand, elephants, and birds, which use their fingers to grasp and handle objects. The bio-inspired gripping technology combined with the DELFA sensor makes the robot hand more versatile and precise.

Improving Process Reliability

The built-in intelligence of the sensors can significantly increase the process reliability of handling operations. The sensors are able to detect errors or defects during production which can be difficult or impossible for humans to detect. The data collected from the sensors can be analyzed to improve the manufacturing process. The system can help reduce waste, improve quality, and ultimately save money.

Weight and component identification

The sensors record weight and provide information on whether the component is the right one. The system can verify that each component being picked up is the correct one and that it falls within the appropriate weight range. Additionally, the sensors can detect any defects or anomalies in components that may not be visible to the human eye.

Dielectric elastomers

The DELFA sensors were developed based on ‘dielectric elastomers’. The material has excellent mechanical properties, such as high elasticity, high elongation, and high dielectric permittivity. The material can be produced in different shapes and forms, making it adaptable to various applications. The DELFA sensors are cost-effective and durable, making them an ideal solution for the robotics industry.

Versatility

DELFA sensors can continuously record and evaluate tensile and compressive forces, as well as positions, strains, or motion sequences. This makes them suitable for a wide range of applications, from picking up delicate objects to handling heavy machinery. The sensors can also be used for tasks such as gripping, manipulating, and assembling. The adaptability of the sensors makes them ideal for use with a variety of robots, including articulated arms, delta robots, and SCARA.

Retrofit Technology

DELFA technology can be retrofitted into existing robot and machine systems. The sensors can be easily integrated into existing robots, which means that companies can enhance the capabilities of their robots without having to invest in expensive new systems. The cost-effectiveness of the sensors makes them a popular choice for companies looking to improve their robotic capabilities.

In conclusion, the development of DELFA technology has paved the way for a new era of powerful and intelligent machines. The sensors have expanded the range of applications in robotics by providing sensitive digital force and displacement measurements. The sensors make machines more efficient and precise, while also improving process reliability. DELFA technology represents the future of intelligent sensors with unique properties and has already revolutionized the robotics industry. This technology will continue to be used in the development of new applications and will help to enhance the capabilities of robots and machines even further.