The hum of the modern factory floor is changing, now harmonizing the relentless precision of machines with the irreplaceable cognitive judgment of human experts to redefine the very essence of manufacturing quality. This transition marks a strategic evolution beyond Industry 4.0, moving from a narrative of pure automation to one of intelligent human-machine collaboration. For a global manufacturing powerhouse like India, this trend is not merely a technological upgrade but a fundamental rethinking of how to achieve superior quality, resilience, and a competitive edge. This analysis will explore the market forces driving this shift, its real-world applications across critical sectors, the perspectives of industry leaders, and the future outlook for this human-centric revolution in quality control.

The Market Shift From Automation to Collaboration

The fourth industrial revolution was defined by the pursuit of the “lights-out” factory, where automation reigned supreme. However, the emerging paradigm of Industry 5.0 recognizes that complex, dynamic manufacturing environments demand more than just machine efficiency. The focus has shifted toward creating synergistic systems where technology augments human capabilities. This collaborative model leverages the strengths of both parties: the tireless consistency and data-processing power of AI and the critical thinking, adaptability, and problem-solving skills unique to humans.

This evolution represents a more mature understanding of technology’s role in the workplace. Instead of aiming to replace workers, Industry 5.0 seeks to empower them. The result is a more resilient, flexible, and efficient production ecosystem capable of delivering a higher standard of quality than either a fully automated or a purely manual system could achieve alone. This collaborative approach is rapidly becoming the new benchmark for excellence in modern manufacturing.

Growth and Adoption Statistics

Market data clearly illustrates this paradigm shift, with a notable surge in the adoption of technologies that enable human-machine collaboration. Credible industry reports project a significant compound annual growth rate for collaborative robots (cobots) in the Indian market from 2026 onward, as manufacturers prioritize solutions that can work safely alongside their human workforce. This growth is mirrored in the machine vision market, where AI-powered systems are no longer niche but a central component of quality assurance strategies.

Furthermore, the market for integrated smart quality control systems, which combine AI, IoT, and Augmented Reality (AR), is expanding rapidly. Indian manufacturers are increasingly investing in these holistic solutions that provide real-time data to human operators, enhancing their decision-making capabilities. This trend signifies a clear move away from siloed automated solutions and toward integrated, human-centric platforms that form the backbone of the Industry 5.0 factory.

Real-World Applications Across Key Sectors

In automotive manufacturing, this collaborative approach is yielding transformative results. Human inspectors, equipped with AR overlays and supported by AI algorithms, can now assess weld integrity, paint finish consistency, and complex component alignments with unprecedented accuracy. This synergy drastically reduces the probability of defects, minimizes the need for costly rework, and helps prevent large-scale recalls. By embedding this higher standard of quality directly into the production line, this trend significantly bolsters the credibility and global competitiveness of the “Make in India” initiative.

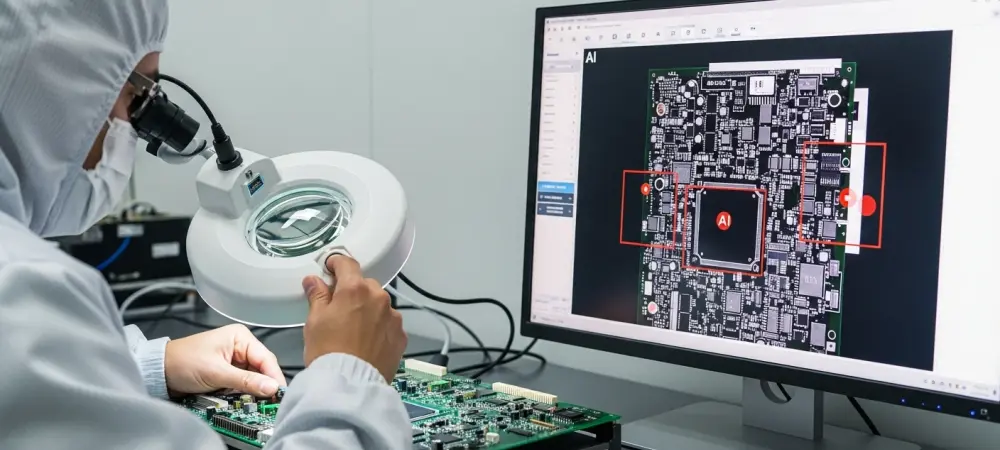

The electronics and semiconductor industry, characterized by microscopic components and zero-tolerance for error, provides another compelling use case. Validating the intricate circuitry on a Printed Circuit Board (PCB) for microscopic flaws is a task that pushes the limits of human vision and is often too nuanced for traditional automated systems. Here, AI-powered machine vision performs the high-speed, high-magnification scanning, flagging even the most subtle anomalies. A human expert then steps in to verify these potential defects, applying their experience to differentiate between a critical flaw and an acceptable variance, thereby ensuring the flawless quality required for high-tech consumer and industrial electronics.

India’s role as the “world’s pharmacy” is being reinforced through the adoption of Industry 5.0 visual inspection in its pharmaceutical and healthcare sectors. In an industry governed by stringent regulatory standards, AI-assisted systems help human inspectors validate the integrity of packaging, confirm the accuracy of labels and batch codes, and detect potential contaminants with exceptional reliability. This human-in-the-loop system not only enhances patient safety but also streamlines compliance, ensuring that products meet the rigorous quality demands of the global market.

Insights from Industry Leaders

Across the manufacturing landscape, a clear consensus has emerged among industry leaders: the goal of Industry 5.0 is not to engineer humans out of the factory but to elevate their role within it. Experts emphasize that this new industrial era is about empowerment, combining the brute analytical power of machines with the nuanced creativity and critical thinking that remain exclusively human domains. Technology is viewed as a powerful tool that frees workers from monotonous, repetitive tasks, allowing them to focus on more complex, value-added activities like root-cause analysis and process innovation.

This synergistic partnership is consistently cited as the key to achieving a level of quality and adaptability that was previously unattainable. A purely automated system, for all its speed, can struggle with novel defects or unexpected variations. A purely manual system is prone to fatigue and inconsistency. However, the collaborative model leverages the best of both, creating a self-improving loop where AI flags potential issues with high precision and humans provide the final judgment and contextual understanding. This combination results in a far more accurate and reliable quality control process.

Furthermore, executives point to the human-centric approach as a critical factor in building more resilient and agile manufacturing operations. In an era marked by frequent supply chain disruptions and volatile market demands, the ability to adapt quickly is paramount. Empowered human workers, augmented by intelligent systems, are better equipped to troubleshoot problems, reconfigure production lines, and make informed decisions on the fly. This adaptability transforms the factory from a rigid, automated entity into a dynamic and responsive organization capable of navigating uncertainty.

The Future Horizon Developments Benefits and Challenges

Looking ahead, the evolution of collaborative visual inspection is set to accelerate with the integration of even more advanced technologies. The development of sophisticated AI capable of predictive quality analytics will be a game-changer, allowing systems to anticipate potential defects before they occur by analyzing real-time data from across the production line. Simultaneously, Augmented Reality interfaces are becoming more intuitive and data-rich, providing inspectors with seamless, context-aware guidance and turning complex schematics into interactive 3D overlays.

The long-term benefits of embracing this trend are profound. Beyond achieving superior product quality, manufacturers stand to gain a significant boost in global competitiveness. Sustainable practices are also inherently promoted, as enhanced inspection accuracy leads to a direct reduction in material waste, rework, and energy consumption. Crucially, this evolution promises to create a new generation of more engaging and skilled jobs, transforming the role of the factory worker from a manual laborer to a tech-augmented problem-solver.

However, the path to adoption is not without its obstacles. The primary challenge remains the significant initial capital investment required to procure and implement advanced cobots, AI software, and AR hardware. Alongside this financial hurdle is the critical need for comprehensive workforce upskilling. For this collaborative model to succeed, companies must invest heavily in training programs that equip their employees with the skills to work effectively alongside intelligent machines, interpret complex data, and manage these new digital workflows.

Conclusion Redefining the Future of Quality

This analysis has established that the transition toward Industry 5.0 was not just a technological refresh but a strategic pivot that placed human ingenuity back at the core of the smart factory. The widespread adoption of collaborative visual inspection has served as a powerful catalyst for this change, enabling manufacturers to achieve unprecedented levels of quality, operational resilience, and sustainability. By embracing a model where technology augments rather than replaces human expertise, Indian industry leaders successfully navigated the complexities of modern production. This human-centric approach has secured a formidable leadership position for the nation in the next chapter of the industrial revolution.