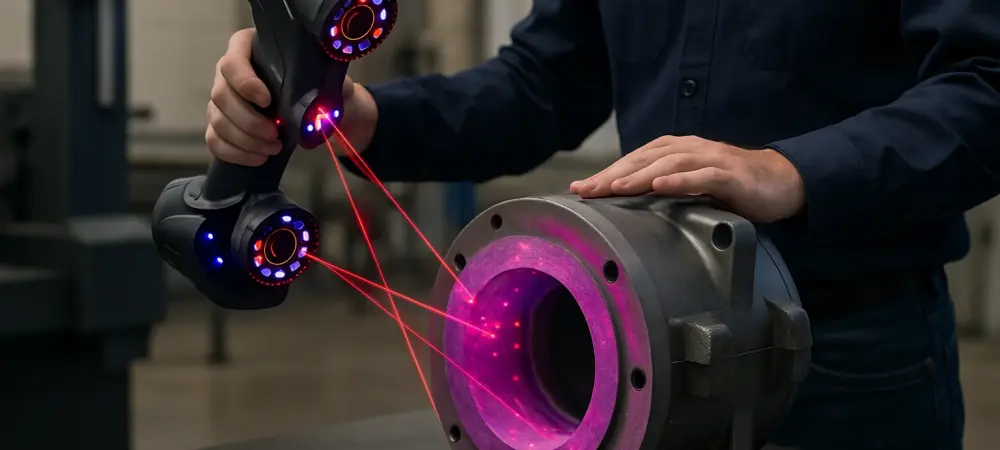

Picture a manufacturing floor where every single part, from intricate machined components to massive car doors, must undergo rigorous quality checks using outdated manual tools like calipers and micrometers, often taking hours and still leaving room for human error that could cost thousands in defective products. This scenario highlights the inefficiencies plaguing traditional industrial inspection methods, underscoring a pressing need for innovation. In an era where precision and speed define competitive advantage, the emergence of 3D scanning technology offers a transformative solution, promising to overhaul quality control processes across industrial settings.

The significance of precision and efficiency in modern manufacturing cannot be overstated, as industries face mounting pressure to deliver flawless products at an unprecedented pace. 3D scanning has emerged as a game-changer, enabling non-contact, high-accuracy inspections that drastically reduce time and error compared to conventional approaches. This trend is reshaping how manufacturers ensure quality, making it a cornerstone of automation in production environments.

This analysis delves into the rise of 3D scanning technology within industrial inspection, exploring its market growth and real-world applications through pioneering examples like the AM-Desk platform. It also incorporates expert insights on its impact, examines future potential, and distills key takeaways for manufacturers navigating this evolving landscape.

The Rise of 3D Scanning in Industrial Inspection

Market Growth and Adoption Trends

The adoption of 3D scanning technology in industrial inspection has surged in recent years, driven by a broader push for automation across manufacturing sectors. According to industry reports, the global 3D scanning market is projected to grow at a compound annual growth rate of over 8% from 2025 to 2030, reflecting strong demand for precision tools in quality control. This growth is fueled by manufacturers seeking to minimize downtime and enhance product reliability in highly competitive markets.

A major factor propelling this trend is the urgent need to eliminate human error in inspection processes, which traditional methods often fail to address. Alongside this, the drive for faster production cycles has made automated solutions like 3D scanning indispensable, as they enable real-time data capture and analysis without halting operations. The technology’s ability to integrate seamlessly with existing systems further accelerates its uptake among forward-thinking companies.

Additionally, the push for digital transformation in manufacturing has positioned 3D scanning as a critical component of Industry 4.0 initiatives. As factories become smarter, the demand for tools that provide detailed, actionable data continues to rise, cementing this technology’s role in modern production strategies. This widespread adoption signals a shift toward data-driven quality assurance on a global scale.

Real-World Impact and Case Studies

A standout example of 3D scanning’s transformative power is the collaboration between Elite Robots and Scanology, which has created the AM-Desk platform, an integrated system combining high-accuracy 3D scanning with collaborative robots. This innovation automates the inspection process, allowing for comprehensive quality checks with minimal human intervention. It represents a significant leap forward in addressing the inefficiencies of manual methods.

The AM-Desk platform finds practical application in diverse scenarios, such as full-part inspection and surface defect detection for components like car doors and machined parts in automotive and general manufacturing. With an impressive accuracy of up to 0.02 mm, the system captures intricate details that manual tools often miss, ensuring defects are identified before they escalate into costly issues. Its ability to scan complex geometries from all angles enhances its utility across varied production lines.

Moreover, the efficiency gains are striking, with scans completed in as little as five minutes, a fraction of the time required by traditional approaches. This rapid turnaround reduces production bottlenecks, enabling manufacturers to maintain tight schedules without compromising quality. The plug-and-play design of the system also simplifies deployment, making it accessible even to facilities with limited technical expertise.

Expert Perspectives on 3D Scanning Advancements

Industry leaders have hailed the integration of 3D scanning with robotics as a pivotal development in industrial inspection, emphasizing its potential to redefine quality standards. Many experts point to the synergy between collaborative robots and advanced scanning systems as a means to achieve unparalleled precision, which is critical in high-stakes sectors like aerospace and automotive. This combination is seen as a cornerstone of next-generation manufacturing.

However, challenges such as high initial investment costs and integration complexities remain a concern, as noted by technology specialists in the field. While the upfront expense of adopting automated systems can be daunting for smaller manufacturers, experts argue that the long-term value—through reduced labor costs and fewer defects—far outweighs these hurdles. They stress the importance of strategic planning to ensure smooth implementation in diverse production environments.

There is also a strong consensus among professionals that automation, including 3D scanning, is no longer optional but a competitive necessity. This view reinforces the trend’s relevance, as companies that fail to adopt such technologies risk falling behind in efficiency and product quality. Expert opinions consistently highlight that embracing these advancements is essential for maintaining market relevance in an increasingly automated industrial landscape.

Future Outlook for 3D Scanning in Industry

Looking ahead, 3D scanning technology is poised for significant advancements, with potential improvements in software integration and compatibility with broader manufacturing systems. Enhanced algorithms could enable even higher accuracy and faster processing of complex data sets, making the technology more versatile for intricate applications. Such developments promise to further streamline quality control processes across various sectors.

The benefits of widespread adoption are substantial, including superior quality assurance and the ability to leverage data for informed decision-making. However, challenges like workforce adaptation to new systems and scalability in smaller operations must be addressed to ensure equitable access to these innovations. Overcoming these barriers will be crucial for maximizing the technology’s impact on a larger scale.

Beyond immediate applications, the implications of 3D scanning extend to industries such as automotive, aerospace, and consumer goods, where it could play a central role in shaping smart manufacturing. As factories evolve into interconnected, data-driven ecosystems, this technology is likely to become a foundational element, driving efficiency and innovation. Its influence may well redefine production standards in the years to come.

Conclusion and Key Takeaways

Reflecting on the journey of 3D scanning in industrial inspection, it becomes evident that its growth marks a turning point for manufacturing, fueled by robust market expansion and practical innovations like the AM-Desk platform. Expert endorsements further validate its impact, while discussions on future possibilities highlight a path toward even greater precision and integration.

The transformative potential of this technology stands out as a defining factor, having proven its capacity to elevate efficiency and accuracy in quality control. Its role in minimizing human error and accelerating production cycles emerges as a critical asset for industries striving to meet modern demands. As a next step, manufacturers are encouraged to explore automated inspection solutions, assessing how tools like 3D scanning can integrate into their operations to boost competitiveness. Investigating partnerships with technology providers and investing in training for seamless adoption offer practical ways to navigate this shift, ensuring readiness for an increasingly automated industrial future.