Shape memory alloys (SMAs) have emerged as groundbreaking technology in the field of micro-robotics. With their unique properties and mechanical reliability, SMAs provide a promising avenue for the development of compact and efficient robotic systems. This article aims to explore the potential of lightweight SMA actuators, specifically focusing on the use of small wires made of shape memory alloy in robots created by researchers at Washington State University (WSU).

Advantages of Shape Memory Alloys in Micro-Robotics

Shape memory alloys possess several inherent advantages that make them ideally suited for micro-robotics. Unlike traditional actuators that incorporate spinning or moving parts, SMAs lack such components, rendering them mechanically sound and highly durable. This unique characteristic allows for seamless integration of SMA systems within micro-robotic structures, enhancing their overall reliability and longevity.

Unleashing the Potential of Lightweight SMA Actuators

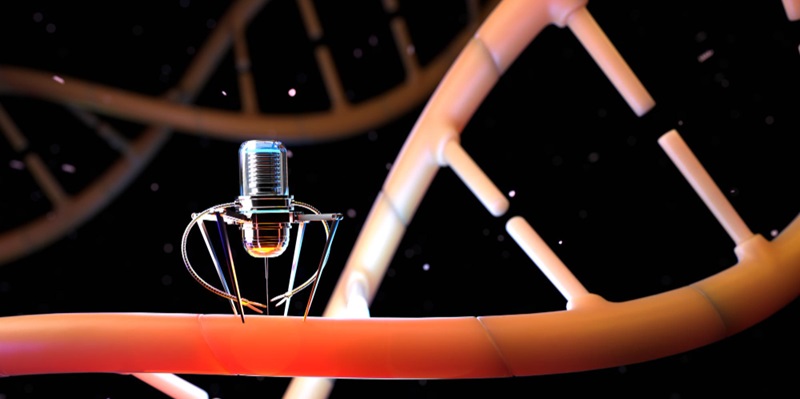

The development of lightweight SMA actuators has paved the way for a new era in micro-robotics. These actuators, made possible through advanced fabrication techniques, offer exceptional performance and versatility. By utilizing shape memory alloy wires, WSU researchers have pioneered a revolutionary approach to enable precise movement in their robots.

One of the key advantages of SMA wires is their ability to be heated or cooled with electricity, providing the robots with swift and seamless movement capabilities. By subjecting the wires to controlled heating or cooling, the WSU robots can navigate with remarkable agility and precision. This feature allows for efficient and nimble locomotion, overcoming the limitations of traditional actuation methods.

Remarkable Lifting Capacity

Preliminary testing of the shape memory alloy actuator in WSU robots has yielded impressive results, showcasing its exceptional lifting capacity. The SMA actuator has shown the ability to effortlessly lift over 150 times its own weight, demonstrating the immense potential of this technology for a wide range of applications.

Efficiency Through Lower Heat and Power Requirements

Compared to conventional actuation techniques, SMA systems require significantly less heat or power to enable robot movement. This efficiency is attributed to the unique phase transformation properties of shape memory alloys. By harnessing the shape memory effect, WSU robots can operate using optimal power levels, minimizing energy consumption and extending their operational lifespan.

Simplified Power Systems for SMA Robotics

Another significant advantage of the SMA system is its compatibility with less sophisticated power systems. Due to their lower heat and power requirements, SMA actuators eliminate the need for complex and bulky power supply units, contributing to the development of more compact and lightweight robots. This simplification of power systems allows for greater maneuverability and enhances the overall portability of SMA-based robotic platforms.

Learning from Water Striders: Enhancing Robot Movements

WSU researchers have drawn inspiration from nature, specifically studying the movement patterns of water striders, to further improve their robotic creations. By mimicking the mechanism through which water striders glide effortlessly on water surfaces, the goal is to develop robots that exhibit similar locomotion both below and above the water’s surface. This innovative approach holds great promise for the exploration of aquatic environments and opens up avenues for various applications, such as environmental monitoring and search and rescue missions.

Towards Autonomous and Untethered Robots

The ultimate aim of WSU’s SMA-based robotics research is to create fully autonomous robots that are untethered from external power supplies. This would allow these micro-robots to operate independently, granting them enhanced mobility and adaptability in a range of environments. Such advancements in autonomy would enable the deployment of these robots in scenarios that were previously inaccessible or deemed too hazardous for human intervention.

Shape memory alloys have proven to be a revolutionary development in micro-robotics, offering unparalleled mechanical reliability and versatile actuation capabilities. The research conducted by WSU, utilizing lightweight SMA actuators, demonstrates the immense potential of this technology for the future of robotics. As advancements continue to be made in this field, the prospect of fully autonomous and untethered robots becomes increasingly attainable, paving the way for a new era of micro-robotics applications.