The recent surge in the Saudi Arabia Robotic Process Automation (RPA) market, particularly within the smartphone manufacturing sector, marks a significant step towards industrial digital transformation. This sector’s burgeoning growth is part of a broader strategy aimed at integrating advanced automation technologies into manufacturing processes. The transformation is driven by the government’s ambitious Vision 2030 initiative, which seeks to position the country as a leader in technological innovation and industrial efficiency.

Market Growth and Projections

The Saudi Arabia RPA market has experienced substantial growth, with the market size expected to reach USD 4.50 million in 2024. Such impressive projections are driven by the increasing demand for automation to enhance manufacturing efficiency and the constant advancements in robotics and artificial intelligence (AI). With the market forecasted to grow at a compound annual growth rate (CAGR) of 20.64%, it is poised to potentially hit USD 24.36 million by 2033. This remarkable growth trajectory underscores the critical role of automation in elevating the production capabilities of smartphone manufacturers and maintaining global competitiveness.

These elements are essential as they enable manufacturers to streamline operations, reduce costs, and improve production accuracy. The need for sophisticated and faster manufacturing processes, driven by consumer demand for advanced smartphone models, further propels the market’s expansion. As manufacturers seek to adopt smarter, more efficient production methods, the integration of RPA technologies becomes indispensable. These advancements in robotics and AI facilitate not only the automation of repetitive tasks but also the enhancement of overall operational efficiency.

Vision 2030 and Industrial Transformation

Central to the rapid expansion of the RPA market is Saudi Arabia’s Vision 2030, an ambitious initiative that aims for comprehensive digital transformation across various sectors. This national initiative underscores the importance of integrating RPA technologies into the manufacturing sector, thereby facilitating the country’s transition into Industry 4.0. Through Vision 2030, the government emphasizes the need for modernization and innovation, which are imperative for the sustained growth and competitiveness of the Saudi economy.

RPA plays a pivotal role in this transformation by significantly improving production and operational efficiency within the smartphone manufacturing sector. By reducing the need for human intervention in repetitive and mundane tasks, RPA allows for greater focus on strategic and high-value activities. This not only enhances productivity but also fosters innovation and technological advancement within the industry. The integration of automation technologies is, therefore, a critical driver in the modernization efforts promoted under Vision 2030.

Operational Efficiency and Technological Adaptation

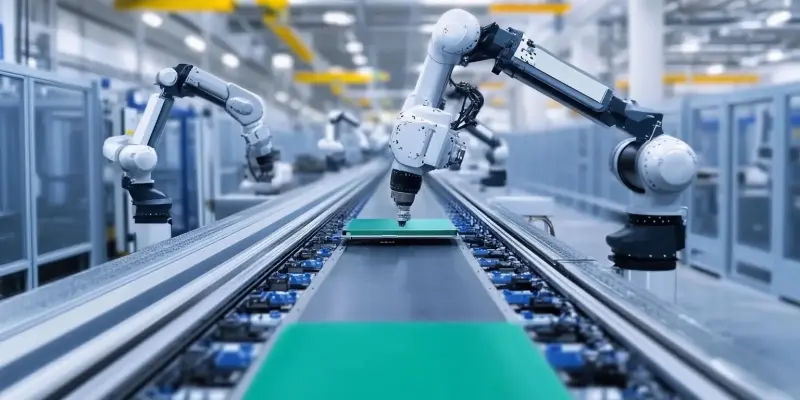

Adopting RPA technologies is proving to be a game-changer in the realm of operational efficiency and technological adaptation within the smartphone manufacturing sector. RPA adoption is increasingly seen in routine tasks such as inventory management, quality checks, and data processing. This shift towards automation aids manufacturers by streamlining operations and boosting productivity, ensuring they keep pace with global industry standards and consumer expectations.

The anticipated rollout of 5G technology further heightens the importance of automation in producing advanced smartphones. The increased need for sophisticated and technically advanced smartphone models necessitates the integration of new automation methods to meet consumer demands. By leveraging RPA, manufacturers can scale their production capabilities, improve accuracy, and maintain a competitive edge in the market. The seamless integration of RPA technologies enables manufacturers to optimize their production processes, reduce errors, and ensure quality control, thereby enhancing overall market competitiveness.

Supply Chain and Predictive Maintenance

Effective supply chain management is paramount for cost reduction and profitability in the highly competitive smartphone manufacturing industry. RPA facilitates this by managing complex workflows, real-time diagnostics, and packaging processes, which are crucial for maintaining efficient operations. The ability of RPA to handle these intricate tasks with precision and speed is invaluable for manufacturers seeking to optimize their supply chain and reduce operational costs.

Moreover, the infusion of artificial intelligence (AI) and machine learning (ML) into RPA systems has enabled the adoption of predictive maintenance strategies. Predictive maintenance capabilities are vital for minimizing downtime and optimizing the production process. By using AI and ML to predict and address potential issues before they lead to equipment failures or production stoppages, manufacturers can significantly reduce downtime and improve production yields. This advanced decision-making capability, facilitated by RPA, enhances overall operational efficiency and supports continuous production improvements.

Investment and Competitive Landscape

An influx of investments into RPA vendors and solution providers highlights the increasingly competitive landscape within Saudi Arabia’s RPA market. These investments, driven by promising market forecasts and robust governmental support, foster an environment conducive to technological advancement and innovative implementation. The Saudi government’s sponsorship of programs aimed at incentivizing internal manufacturing and RPA technology adoption is also pivotal in stimulating market growth.

These initiatives are essential for ensuring that the country remains at the forefront of digital transformation in manufacturing. By supporting RPA technology adoption, the government helps create fertile ground for innovation, which in turn attracts further investments from both local and international players. The competitive landscape is thus characterized by a dynamic interplay of innovation, investment, and supportive policies, all of which collectively drive the market’s expansion.

Global Collaborations and Alliances

Strategic alliances between international RPA technology players and local businesses act as a key driver for the expansion of the RPA market in Saudi Arabia. These collaborations facilitate knowledge transfer, enhance local capabilities, and ultimately boost the competitiveness of Saudi manufacturers in the global arena. Partnerships with leading U.S. automation firms and other global industry players enable the implementation of comprehensive, end-to-end RPA systems.

These systems are meticulously designed to scale production precision and improve turnaround times, particularly in the intricate processes of smartphone assembly lines. By partnering with global firms, local manufacturers gain access to cutting-edge technologies and industry best practices. Such collaborations are crucial for developing a robust and competitive RPA ecosystem within Saudi Arabia.

Regional Impact

The recent upswing in the Saudi Arabian Robotic Process Automation (RPA) market, notably within the smartphone manufacturing industry, signifies a critical advance in the nation’s industrial digital transformation efforts. This sector’s rapid development reflects a larger strategy to incorporate cutting-edge automation technologies into manufacturing operations. The momentum behind this shift is largely fueled by the Saudi government’s ambitious Vision 2030 initiative. This comprehensive plan aims to establish Saudi Arabia as a global leader in technological innovation and industrial efficiency. By embracing advanced automation, the country seeks to diversify its economy, reduce its dependency on oil, and create more sustainable growth opportunities. Vision 2030 encompasses a broad range of objectives, including enhancing the quality of life for its citizens and reforming various sectors of the economy. The integration of RPA in manufacturing is a crucial part of this initiative, enabling companies to streamline processes, improve productivity, and maintain a competitive edge in the global market.