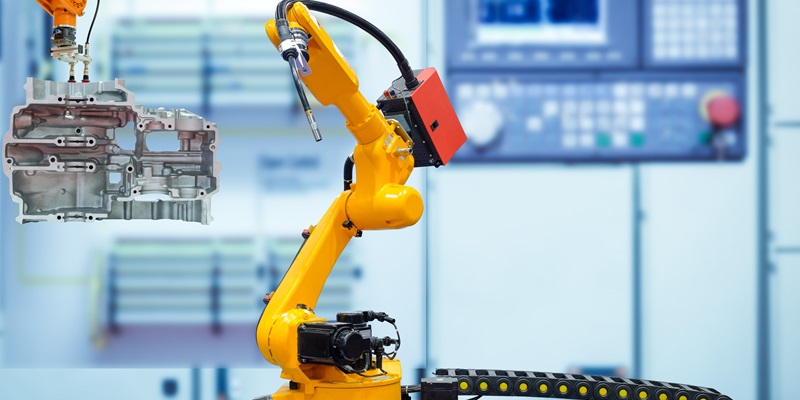

In today’s rapidly evolving technological landscape, researchers are constantly pushing the boundaries of what robots can achieve. One groundbreaking research project focuses on addressing the issue of a robot autonomously changing a previously acquired task without the need for human intervention. This research initiative, funded by the European Union with eight million euros, aims to revolutionize industries by introducing autonomous task change capabilities in robots. The project will have applications in two key industries: automotive and heavy industries.

Objective of the project

The ultimate objective of this pioneering project is to enable robots to utilize environmental information and intelligently analyze the requirements of their operating environment. Additionally, the robot will be equipped with the ability to disassemble batteries with precision and efficiency. This capability holds tremendous potential for industries that heavily rely on battery-powered machinery and equipment. By automating the disassembly process, the project aims to improve operational efficiency and reduce the risk of accidents in the workplace.

Current challenges in industries

In the heavy mechanical sector, the battery disassembly process is currently performed by an operator who also operates an overhead crane. This complex operation often forces the operator to work in uncomfortable and unsafe postures, increasing the likelihood of accidents.

The project recognizes these challenges and aims to alleviate them by introducing autonomous task change capabilities in robots. By doing so, operators can be relieved from the physically demanding aspect of the job, allowing them to focus on overseeing the overall manufacturing process.

Role of operators in the manufacturing process

While the project aims to automate certain tasks, it is crucial to emphasize that human operators will still play a significant role in overseeing the job. Operators will retain the responsibility of ensuring the smooth functioning of the manufacturing process, while robots handle repetitive and physically demanding tasks. The symbiotic partnership between humans and robots will not only enhance efficiency but also foster a safer working environment.

Compliance with EU policies

This research initiative aligns perfectly with the European Union’s policies for the green and circular economy. By introducing autonomous task change capabilities in robots, industries can streamline their operations, reduce waste, and promote sustainable practices. This project stands as a prime example of how technological advancements can be leveraged to meet the EU’s sustainability goals.

Measurement of industrial waste

To further aid in the removal of industrial waste, the robotic devices developed in this project will possess the capability to measure a product’s energy efficiency, greenhouse gas emissions, resource consumption, and recycling rate. These measurements will provide valuable insights for companies seeking to optimize their production processes, reduce environmental impact, and enhance overall sustainability. With this data-driven approach, industries can make informed decisions that lead to more efficient waste removal and a reduced environmental footprint.

Innovative Solutions for Battery Disassembly

One of the most ambitious aspects of this research project is the development of incredibly creative solutions and adaptable learning strategies that rapidly adjust to the unique components of batteries. The project partner, Inverse, has set out to automate the battery disassembly process using state-of-the-art robotics technology. By leveraging machine learning and advanced algorithms, Inverse aims to streamline the disassembly process, increasing efficiency and reducing reliance on manual labor.

Funding and support

The European Union’s generous funding of eight million euros for this Research and Innovation Action initiative is a testament to its commitment to advancing research and innovation in key industries. This support provides a significant boost to the project’s progress and greatly enhances its potential for impact.

The introduction of autonomous task-change capabilities in robots has the potential to revolutionize industries, such as automotive and heavy industries. By implementing robots that can investigate environmental demands and autonomously disassemble batteries, companies can achieve heightened efficiency and improved safety standards. Furthermore, the adoption of such advanced robotic technologies aligns perfectly with EU policies for the green and circular economy, thereby reinforcing a commitment to sustainable practices. As this research project continues to unfold, it promises to shape the future of industries, enabling them to thrive in an increasingly technologically-driven world.