In the fast-paced and highly competitive world of fabless semiconductor production, efficient inventory management plays a crucial role in driving success. However, traditional ERP inventory systems often fall short when it comes to meeting the unique requirements of this industry. This article explores the limitations of these systems and highlights the revolutionary capabilities of Tensoft SemiOps, an advanced inventory management solution designed specifically for fabless semiconductor production.

The Need for Specialized Inventory Systems in Fabless Semiconductor Production

Traditional ERP inventory systems are not inherently equipped to handle the intricate and complex processes involved in fabless semiconductor production. The product attributes and production steps involved in this industry require a specialized solution.

To effectively address the requirements of fabless semiconductor production, it is crucial to have an inventory management system that is specifically designed to fit the unique needs and processes of the industry. Tensoft SemiOps is a comprehensive solution that effortlessly adapts to diverse semiconductor production workflows.

Key Features of Tensoft SemiOps

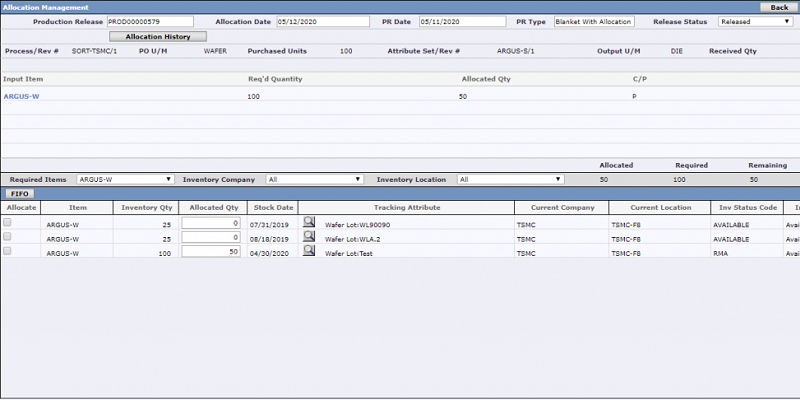

Tensoft SemiOps offers a powerful tracking and documentation system, ensuring a complete and auditable process history for every vendor and production step. This enables semiconductor companies to have full visibility and control over their supply chain.

Tracking wafer lots, vendor lots, and internal lots at every step of the production process is vital for quality control and traceability. Tensoft SemiOps enables seamless monitoring and management of lot information, ensuring accuracy and efficiency.

Fabless companies require precise tracking of product attributes throughout the production process. Tensoft SemiOps provides robust capabilities to track and manage detailed product attributes, enabling better decision-making and enhanced product quality.

Tensoft SemiOps offers comprehensive support for standard cost variables, ensuring accurate costing and financial analysis. This feature enables companies to gain a better understanding of their production costs and make data-driven decisions.

Flexibility is essential in the fast-paced semiconductor industry. Tensoft SemiOps allows for reworking, rescreening, and retesting, empowering manufacturers to optimize yield and quality without sacrificing efficiency.

Tensoft SemiOps goes beyond in-house operations by integrating with manufacturing subcontractors. This streamlined collaboration ensures a seamless flow of information, enhancing productivity and coordination across the entire supply chain.

Advantages of Tensoft SemiOps over Traditional ERP Inventory Systems

Tensoft SemiOps offers a cost-effective and customizable alternative to traditional ERP inventory systems, eliminating the need for expensive customizations or workarounds.

Unlike generic ERP solutions, Tensoft SemiOps provides industry-specific features and functionalities tailored to the unique requirements of fabless semiconductor production. It streamlines operations, improves efficiency, and enhances overall productivity.

Tensoft SemiOps delivers comprehensive support for work-in-progress (WIP) and inventory management, enabling accurate real-time inventory control, minimising stockouts, and optimising production workflows.

Tensoft SemiOps presents a revolutionary solution that addresses the inherent limitations of traditional ERP inventory systems in fabless semiconductor production. With its specialized features, comprehensive tracking capabilities, flexibility, and seamless integration, it empowers companies to streamline processes and maximize productivity. By embracing this innovative inventory management system, fabless semiconductor companies can gain a competitive edge and drive future success in this ever-evolving industry.