Augmentus, an intelligent 3D scanning and robot motion planning solutions company, is expanding its presence in the international market by entering Europe. The company aims to make its technology available to meet the increasing demand for simplified robot programming solutions in Europe. Augmentus has pioneered intelligent 3D scanning and AI robot motion planning systems that enable no-code robot programming in minutes, allowing non-technical operators to plan robot motions for both industrial and collaborative robots quickly. This results in a quick return on investment.

There is an increasing demand for simplified robot programming solutions in Europe

Europe has been a hub for the manufacturing industry for decades. As the manufacturing industry evolves, so does the need for efficient and simple robotic programming solutions. In the past, robotic programming has required technical expertise, and the process could take weeks or even months. However, with the increasing demand for automation and smart manufacturing, there has been a shift towards simplified robot programming solutions. Augmentus’ entry into the European market will bring its innovative technology to meet the demands of the region’s manufacturing industry.

Augmentus’ intelligent 3D scanning and AI robot motion planning systems

Augmentus’ proprietary technology enables no-code robot programming in minutes. The company has developed intelligent 3D scanning and AI robot motion planning systems to simplify the robotic programming process. Non-technical operators can easily plan robot motions for both industrial and collaborative robots, resulting in a significant reduction in programming time and cost. With Augmentus’ technology, engineering costs can be reduced by up to 73%, and robot programming duration can be reduced by 21 times.

Augmentus’ Clientele

Augmentus’ technology has already been adopted by the world’s leading manufacturing companies, such as ST Engineering, Hyundai, Abrasive Engineering, Johnson & Johnson, and Fujitsu. These companies have recognized the potential of Augmentus’ technology to revolutionize the way robots are programmed and utilized in their respective industries. Augmentus’ technology has allowed these companies to reduce engineering costs, increase efficiency, and ultimately improve their overall bottom line.

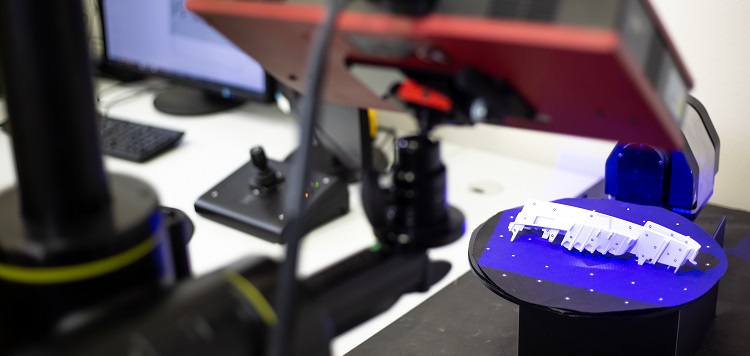

Augmentus showcased its AI-powered robotics system at the Hannover Messe

To showcase its innovative technology to the European market, Augmentus has announced that it will be exhibiting at the Hannover Messe in Germany from April 17-21, 2023. This exhibition will allow firms in the region to experience the versatility and capabilities of Augmentus’ Scan and Plan robotics in simplifying robotics motion planning processes. Augmentus’ participation in Hannover Messe is a testament to the company’s commitment to bringing its technology to the European market.

Augmentus’ Compatibility with Major Robot Manufacturers

Augmentus is compatible with over ten major robot manufacturers, including ABB, Universal Robots, Kuka, and Nachi. This compatibility adds to the versatility of Augmentus’ technology, allowing more companies to adopt it in their existing systems. Augmentus’ technology can integrate with most industrial and collaborative robots, providing a complete package for simplified robot programming solutions.

Augmentus’ Focus on Various Industries

Augmentus’ technology has the potential to become a game-changer across a variety of industries. The company focuses on enabling robotic sandblasting, thermal spraying, shot peening, sanding, polishing, and welding applications. With Augmentus’ technology, robotic programming in these industries can be simplified, making the adoption of automation easier and more efficient.

Augmentus’ expansion into Europe is a significant step towards revolutionizing the way robots are programmed and utilized in the manufacturing industry. Augmentus’ technology has the potential to simplify the robotic programming process, reducing time and cost for engineering and programming. With its compatibility with major robot manufacturers and focus on various industries, Augmentus is poised to revolutionize the way robots are used in manufacturing. The company’s potential impact on the future of robot programming and manufacturing processes is immense.