The software aims to streamline maintenance workflows, automate scheduling tasks, and integrate seamlessly with Business Central’s core features, thereby facilitating a transition from reactive to proactive maintenance approaches. This shift enables businesses to optimize resource utilization, reduce equipment failures, and lower maintenance costs. Through this innovative app, Insight Works aims to revolutionize how companies manage their maintenance tasks, ensuring efficiency and productivity are maximized.

Streamlined Maintenance Workflows

Automated Preventive Maintenance Scheduling

The app substantially reduces downtime by automatically triggering service alerts based on usage, runtime, or calendar intervals. This proactive approach ensures that maintenance is performed at the optimal time, preventing unexpected equipment failures and extending the life of assets. Maintenance Manager’s scheduling feature is designed to anticipate maintenance needs accurately, reducing the likelihood of costly unplanned repairs or replacements. By aligning maintenance activities with equipment usage patterns, businesses can better predict when maintenance should occur, enhancing operational efficiency and equipment longevity.

Furthermore, this preventive maintenance scheduling is integral to moving away from a reactive maintenance approach. Instead of waiting for failures to occur, the app allows businesses to address potential issues before they disrupt operations. The ability to automate these processes means that maintenance managers can focus on more strategic tasks, such as optimizing asset performance and cost management, rather than getting bogged down by manual scheduling and tracking. This proactive strategy not only minimizes downtime but also contributes to overall cost savings by reducing the frequency and severity of equipment breakdowns.

Efficient Work Order Management

Maintenance Manager streamlines the creation, assignment, and tracking of maintenance tasks for efficient execution. By centralizing maintenance operations within Business Central, it eliminates the need for manual tracking and enhances overall work order management. This integration ensures that maintenance tasks are managed in a cohesive and organized manner, providing transparency and accountability within maintenance teams. Every stage of the maintenance workflow, from initial task creation to final completion, is monitored and recorded within the app, ensuring that no detail is overlooked.

By simplifying work order management, Maintenance Manager helps maintenance teams collaborate more effectively. Technicians receive clear instructions and priorities for each task, reducing the chances of miscommunication or errors. Real-time updates allow managers to monitor progress and make adjustments as needed, ensuring that maintenance activities are completed on schedule. The app’s intuitive interface and user-friendly design make it easy for users to navigate and manage their tasks, boosting overall productivity and efficiency.

Seamless Business Central Integration

Leveraging Business Central Data

By integrating with Business Central, Maintenance Manager leverages existing data for maintenance planning, eliminating the need for external tools. This integration ensures a cohesive and comprehensive approach to maintenance management. With access to Business Central’s extensive data on asset performance, usage patterns, and historical maintenance activities, Maintenance Manager offers a data-driven framework for planning and executing maintenance tasks. This seamless connection enables businesses to utilize their existing data infrastructure, resulting in more accurate and reliable maintenance schedules and strategies.

Utilizing Business Central data also means that all maintenance-related information is stored within a single platform, enhancing visibility and accessibility. Maintenance Manager can easily pull relevant data from Business Central’s production, inventory, and asset management modules, creating a unified environment for managing all aspects of maintenance. This integration simplifies data management and ensures that maintenance decisions are informed by the most accurate and up-to-date information available. As a result, businesses can achieve greater operational efficiency and effectiveness, reducing the time and resources required to manage their maintenance activities.

Real-Time Mobile Access

Field technicians are equipped with mobile tools to update maintenance records on the go. This real-time access accelerates task completion and ensures that maintenance activities are recorded accurately and promptly. Mobile access is a critical feature in modern maintenance management, allowing technicians to access work orders, update task statuses, log completed activities, and note any issues from anywhere. This capability enhances the responsiveness of maintenance teams, enabling them to address problems and complete tasks more quickly, which in turn, minimizes downtime and enhances productivity.

The app’s mobile functionalities also improve communication and coordination among maintenance teams. Technicians can receive real-time notifications about new tasks, updates, or changes, ensuring that everyone is on the same page. This real-time communication reduces the likelihood of delays or misunderstandings and enhances the overall efficiency of maintenance operations. Additionally, mobile access means that maintenance records are consistently up-to-date, providing managers with immediate insights into the status of maintenance activities and facilitating better-informed decision-making.

Enhanced Asset and Inventory Management

Parts & Inventory Tracking

The app ensures the availability of spare parts by linking maintenance tasks with Business Central’s inventory system. This integration helps in maintaining optimal inventory levels and reduces the risk of stockouts during critical maintenance activities. With Maintenance Manager, businesses can automate the tracking of spare parts usage and reorder parts proactively based on predefined thresholds. This proactive approach to inventory management ensures that the necessary components are always on hand when needed, avoiding costly delays due to the unavailability of critical parts.

Moreover, linking maintenance tasks with inventory data allows for more precise planning and allocation of resources. Maintenance managers can forecast future parts needs based on historical data and current usage patterns, facilitating more effective budgeting and inventory control. This integration not only reduces the administrative burden associated with manual inventory management but also enhances the overall efficiency and reliability of maintenance operations. By ensuring that the right parts are available at the right time, businesses can minimize downtime and maintain continuous operations.

Historical Maintenance Data Analysis

Maintenance Manager analyzes equipment service history to identify recurring issues and optimize maintenance schedules. This data-driven approach helps in making informed decisions and improving asset longevity. By examining historical maintenance data, the app can identify patterns and trends that indicate potential problems or inefficiencies in the maintenance process. This insight enables maintenance managers to adjust schedules, refine preventive maintenance strategies, and allocate resources more effectively to address recurring issues.

Analyzing historical maintenance data also provides valuable information for continuous improvement. By understanding the root causes of equipment failures or frequent maintenance needs, businesses can implement targeted measures to enhance equipment performance and reliability. This comprehensive view of maintenance history helps in establishing best practices, improving maintenance processes, and ultimately extending the lifespan of critical assets. The ability to leverage historical data in this way transforms maintenance management from a reactive endeavor into a strategic, proactive approach that drives long-term benefits.

Advanced Scheduling and Customization

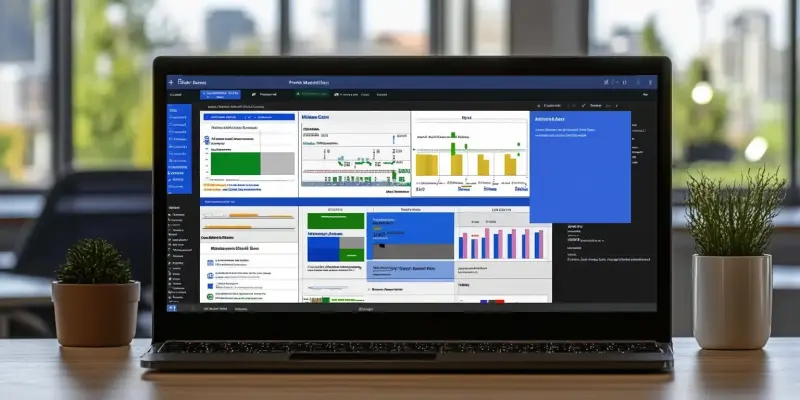

Graphical Scheduling & MxAPS Integration

The app provides visual scheduling and automated planning using Advanced Planning & Scheduling (MxAPS). This feature enhances the ability to plan maintenance activities efficiently, reducing operational disruptions. With graphical scheduling, maintenance managers can visually map out maintenance tasks, ensuring that each activity is strategically timed to minimize impact on production. This visual approach simplifies the complex task of maintenance planning, providing clear and intuitive tools for managing schedules and resources effectively.

MxAPS further elevates maintenance planning by offering automated, optimized scheduling based on a range of variables, such as equipment availability, maintenance priorities, and resource constraints. This advanced planning capability allows businesses to balance maintenance needs with production demands, ensuring that maintenance activities are conducted at the most opportune times. By reducing the guesswork and manual effort involved in scheduling, MxAPS helps businesses achieve greater efficiency and flexibility in their maintenance operations, ultimately reducing downtime and increasing productivity.

Customizable Workflows

Businesses can adapt and configure maintenance processes to meet specific needs. This flexibility ensures that Maintenance Manager can cater to a wide range of industries and maintenance requirements. The app’s customizable workflows allow businesses to define and modify maintenance procedures to align with their unique operational requirements and preferences. This adaptability is particularly valuable for businesses in diverse sectors, each with its own set of maintenance challenges and standards.

Customizable workflows also empower businesses to continuously refine and improve their maintenance processes. As operational needs evolve or new challenges emerge, maintenance managers can adjust workflows to incorporate best practices, address new requirements, and enhance overall efficiency. This ability to tailor maintenance processes ensures that Maintenance Manager remains a relevant and effective tool, regardless of changes in the business environment. By supporting flexible and dynamic maintenance management, the app enables businesses to innovate and stay competitive in their respective industries.

Comprehensive Asset Management

Warehouse & Fixed Asset Management

Maintenance Manager tracks and manages maintenance-related assets within Business Central’s inventory and warehouse functions. This integration streamlines asset management and ensures that all maintenance activities are aligned with the overall business operations. By consolidating asset management within a single platform, businesses can achieve a holistic view of their maintenance-related assets, from fleet vehicles and production equipment to warehouse inventory. This comprehensive approach simplifies asset tracking, improves coordination across different departments, and enhances the accuracy of maintenance records.

The app’s capabilities in managing warehouse and fixed assets extend beyond just tracking and scheduling maintenance tasks. It also provides tools for monitoring asset performance, tracking depreciation, and planning for future asset needs. This integrated asset management approach helps businesses make more informed decisions about asset utilization, maintenance investments, and long-term strategic planning. By aligning maintenance activities with broader business goals, Maintenance Manager contributes to improved operational efficiency, reduced costs, and enhanced asset performance and longevity.

Reduced Complexity and Cost

Maintenance Manager app is specifically developed to improve maintenance processes within Microsoft Dynamics 365 Business Central. Its purpose is to streamline maintenance workflows by automating scheduling tasks and integrating seamlessly with the core features of Business Central. This integration facilitates a transition from reactive to proactive maintenance approaches, which helps businesses optimize resource utilization, minimize equipment failures, and reduce maintenance costs. Through this innovative app, Insight Works aims to transform the way companies handle their maintenance tasks, ensuring maximum efficiency and productivity. By leveraging this app, companies can adopt a more systematic and proactive method for maintaining equipment, ultimately driving down costs and preventing breakdowns. Insight Works’ Maintenance Manager app represents an important advancement in maintenance management, offering significant benefits to businesses using Microsoft Dynamics 365 Business Central.