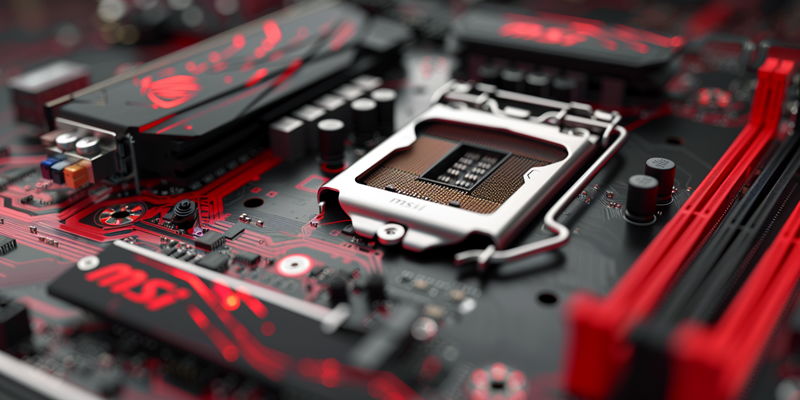

Tech enthusiasts investing in top-tier hardware, such as the MSI Z790 chipset motherboards, expect exceptional quality. Unfortunately, recent reports indicate a manufacturing issue that’s causing concern. The problem in question centers around the Platform Controller Hub (PCH), the nerve center of these motherboards. Some users have reported cracks in the PCH—a serious issue that could potentially lead to component failure if not addressed.

This flaw is an unexpected blemish on MSI’s reputation for high-end build quality. The PCH is integral to the motherboard’s operation, interfacing between the CPU and other critical elements. Its failure can cripple the motherboard, turning a powerhouse into a paperweight. This highlights the importance of rigorous quality control in manufacturing complex electronic hardware. Users affected by this issue are likely seeking solutions or replacements from MSI to ensure their systems remain reliable and high-performing. As the situation unfolds, MSI may need to take steps to rectify the defect and restore confidence in their premium motherboard offerings.

Discovery of the Flaw

A YouTuber and repair technician named Joshi Repair brought the issue to public attention with a detailed examination using a thermal camera. These findings broadcast the severity of the defect, suggesting it originated during the manufacturing process. The PCH is instrumental in a motherboard’s operation, handling communication between the processor and other system components. Thus, the defect’s implications are significant, affecting not just the performance but also the longevity of these premium motherboards which are compatible with Intel’s 12th and 13th Gen processors and anticipated to support the 14th Gen as well.

MSI’s Acknowledgment and Action Plan

Upon discovering a defect in their Z790 motherboards related to a heatsink screw, MSI took swift and decisive action. The thorough investigation identified that the flaw was specifically associated with the screw’s design. Without hesitation, MSI displayed an unwavering commitment to the quality of their products by making immediate changes to the production process to eliminate the fault entirely. By addressing the problem promptly, MSI was able to uphold its reputation for reliability and cement its position as a trustworthy brand in the high-end motherboard market. This responsiveness is particularly vital given the premium expectations that customers have for MSI’s products. The company’s proactive management of the issue exemplifies their overall dedication to customer satisfaction and product excellence, ensuring that such defects are unlikely to reoccur.

Customer Support and Rectification Measures

For users who unfortunately purchased a defective motherboard, MSI has extended a reassuring hand. The company promised product replacements and pledged full support through its customer service channels. This commitment to accountability is not often seen and reflects well on MSI’s dedication to its customers. MSI’s transparent communication and remedy proposals have likely helped ease concerns among its clientele, underscoring the company’s readiness to uphold high standards even when facing unexpected manufacturing snags.

Impact on MSI’s Reputation

MSI’s swift action to address the Z790 motherboard defect showcases its commitment to customer satisfaction. Such proactive measures in handling manufacturing mishaps highlight the significance of responsible corporate behavior and swift service—key elements in upholding a brand’s image. This scenario underscores the importance of thorough quality checks in the electronics sector where high performance and consumer trust are crucial.

MSI’s response to the hardware failure is not merely about the technical fix; it’s a testament to the company’s dedication to its client base in a fiercely competitive environment. As an illustrative example for the tech industry, MSI’s handling of the incident reinforces the idea that the value of a company is measured by its ability to maintain reliability and swiftly rectify issues without compromising consumer confidence.