In an era where smartphones are scrutinized for every feature and specification, a groundbreaking examination has brought to light hidden imperfections in one of the most celebrated devices on the market, the iPhone 17 Pro, through an innovative imaging technique known as wiggle stereoscopy. This detailed microscopic analysis has uncovered subtle yet intriguing flaws that are invisible to the naked eye. This method, applied by a dedicated tech enthusiast, offers a fresh perspective on the intricacies of high-end smartphone design and manufacturing. Far beyond the glossy marketing and polished reviews, this exploration delves into the minute details of components like the camera system and OLED display, revealing aspects that even the most discerning users might overlook. It raises compelling questions about the precision of mass production and the standards upheld by leading tech giants. This analysis not only captivates with its visual depth but also sparks a broader conversation about what perfection truly means in consumer electronics.

Unveiling Hidden Imperfections with Wiggle Stereoscopy

A remarkable aspect of this analysis lies in the use of wiggle stereoscopy, a specialized imaging technique that simulates spatial depth without requiring true 3D vision. This method allows for an unprecedented close-up view of the iPhone 17 Pro, exposing details that standard photography simply cannot capture. By oscillating between two slightly different perspectives, wiggle stereoscopy creates a dynamic visual effect that highlights the smartphone’s internal and external features with striking clarity. The technique has revealed unexpected elements, such as minute dust particles embedded within the camera lenses, which point to potential gaps in the assembly process. While these imperfections may not drastically affect everyday performance, their presence under such detailed scrutiny underscores the challenges of achieving flawless production at scale. This innovative approach not only enhances the understanding of device construction but also sets a new benchmark for how technology can be evaluated beyond surface-level assessments.

The implications of this imaging method extend far beyond a single device, offering a tool for broader industry analysis. When applied to the iPhone 17 Pro, wiggle stereoscopy distinguishes between dust accumulated during manufacturing and that which may settle after unboxing, providing insight into different stages of a product’s lifecycle. Such precision in identifying contaminants could prompt manufacturers to refine their quality control measures, especially in critical components like camera systems. Although the impact of dust on image quality appears minimal—particularly when compared to more disruptive factors like fingerprints or oily smudges in low-light conditions—it still raises questions about consistency across brands. This technique’s ability to uncover hidden flaws could influence consumer expectations, pushing for greater transparency in how devices are assembled. As a result, wiggle stereoscopy emerges as a powerful ally in dissecting the minutiae of modern technology, fostering a deeper appreciation for the complexities involved.

Camera System Under the Microscope

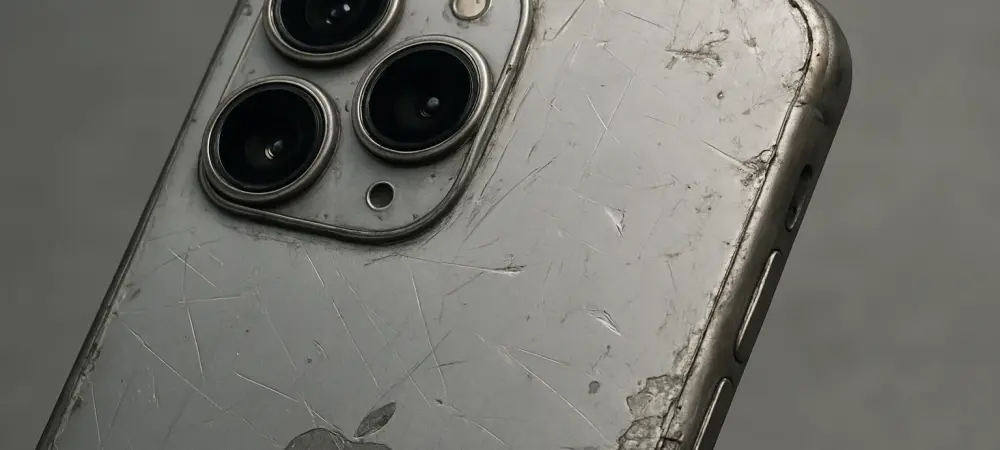

One of the most striking revelations from this microscopic analysis is the presence of dust within the iPhone 17 Pro’s camera system, a component often touted for its cutting-edge clarity and precision. This discovery, made possible through the detailed imaging of wiggle stereoscopy, highlights particles that are otherwise imperceptible to users during regular operation. While the dust does not seem to significantly degrade image quality under typical conditions, its existence suggests that even the most advanced manufacturing processes are not immune to minor oversights. This finding is particularly noteworthy in an era where smartphone photography is a key selling point, often used to capture professional-grade images. The analysis prompts a closer look at how environmental factors are managed during production, especially for a device positioned at the premium end of the market. Such insights could drive improvements in sealing techniques or assembly environments to minimize such intrusions.

Further examination of the camera system reveals a distinction between dust embedded during the manufacturing phase and that which may accumulate over time through regular use. This differentiation is critical, as it points to specific areas where quality control might be tightened to prevent initial contamination. Although the practical impact on performance remains negligible for most users—especially when compared to external factors like lens smudges that can cause flare in bright highlights—these findings still cast a spotlight on the meticulous standards expected from top-tier devices. The presence of dust, however subtle, could influence perceptions of durability and craftsmanship, particularly among enthusiasts who value flawless engineering. As smartphone cameras continue to evolve with increasingly complex sensor arrays and lens designs, ensuring an impeccable build becomes even more paramount. This microscopic view thus serves as a reminder of the unseen challenges that manufacturers must address to maintain trust in their flagship products.

Dissecting the OLED Display’s Complex Layers

Turning attention to the iPhone 17 Pro’s OLED display, the wiggle stereoscopy technique unveils a multi-layered structure that goes beyond the flat, vibrant screen users interact with daily. This detailed visualization showcases distinct components within the display, such as a probable touch layer grid positioned above the pixel layer, highlighting the sophisticated engineering behind modern screens. Although not all layers are fully discernible through this method, the analysis hints at the intricate balance of functionality and design that defines cutting-edge display technology. The edges of the screen also reveal minor material loss, a common challenge in manufacturing that recent advancements, like deep UV laser cutting, aim to mitigate to less than a pixel’s width. Such insights provide a glimpse into the ongoing innovations aimed at perfecting screen durability and visual fidelity, reinforcing the importance of precision at every level of production.

Beyond the structural revelations, this examination of the OLED display sparks curiosity about future comparisons, such as between modern tandem OLED panels and traditional single-layer designs. The ability to visualize these layers through wiggle stereoscopy offers a unique opportunity to understand how each contributes to the overall user experience, from touch responsiveness to color accuracy. While the observed material loss at the edges does not appear to impact performance noticeably, it underscores the relentless pursuit of perfection in an industry where even the smallest flaw can be magnified under scrutiny. As display technologies evolve, techniques like this could play a pivotal role in benchmarking progress and identifying areas for refinement. This microscopic perspective not only deepens appreciation for the complexity of OLED screens but also emphasizes the need for continuous improvement in manufacturing processes to meet the high expectations set by premium devices like the iPhone 17 Pro.

Broader Implications for Tech Analysis

The application of wiggle stereoscopy to consumer electronics like the iPhone 17 Pro signals a growing trend of using specialized imaging to explore everyday technology in unprecedented detail. Typically employed in fields unrelated to tech, such as studying natural subjects or materials, this technique’s adaptation to smartphones demonstrates its versatility and potential to captivate audiences with visually striking insights. By revealing hidden aspects of device design—from dust in camera systems to layered display structures—this approach fosters discussions on manufacturing standards and technological innovation. It also highlights how such detailed analyses can shift consumer perspectives, encouraging a more critical view of quality control among leading manufacturers. As these methods gain traction, they could redefine how the industry evaluates and communicates the intricacies of product assembly, bridging the gap between technical complexity and public understanding.

Moreover, this microscopic examination reflects a broader fascination with uncovering the unseen elements of premium technology, prompting questions about what constitutes true perfection in mass-produced devices. The findings related to the iPhone 17 Pro, while not necessarily indicative of widespread issues, underscore the inherent challenges of maintaining consistency across millions of units. This trend of detailed tech analysis could inspire manufacturers to adopt more rigorous testing protocols or even incorporate similar imaging techniques into their quality assurance processes. Beyond immediate implications, it nurtures a culture of curiosity and accountability, where consumers and creators alike engage in a dialogue about design integrity. As specialized tools like wiggle stereoscopy become more accessible, their role in dissecting consumer electronics will likely expand, offering fresh lenses through which to view the ever-evolving landscape of technology.

Reflecting on Microscopic Revelations

Looking back, the meticulous analysis of the iPhone 17 Pro through wiggle stereoscopy provided a fascinating glimpse into the unseen intricacies of a flagship device, exposing subtle imperfections like dust in the camera system and the layered complexity of the OLED display. This examination underscored the power of niche imaging techniques to reveal details that standard evaluations often miss, enriching the understanding of modern smartphone craftsmanship. Moving forward, these insights could catalyze improvements in manufacturing precision, encouraging industry leaders to refine assembly processes and elevate quality standards. As similar analytical methods become more prevalent, they promise to empower consumers with deeper knowledge, fostering informed expectations about premium technology. Ultimately, this exploration highlighted the value of looking beyond the surface, suggesting that the future of tech assessment lies in embracing innovative tools to uncover and address even the smallest of flaws.