Triggering Industrial Transformation

Sudden spikes in industrial demand have prompted a critical question: Is IoT truly revolutionizing the landscape for industry giants like IVECO? Promises of IoT ushering in eras of smart manufacturing and operational efficiency abound. By exploring the complexities of the digital realm, particularly the Industrial Internet of Things (IIoT), IVECO aims to elevate its status within the automotive sector. As pressures for sustainability and innovation surge, the role of IoT in shaping these endeavors grows ever more prominent.

Understanding the Digital Transformation Wave

For IVECO and companies alike, digital transformation isn’t merely a technological upgrade. It represents a strategic pivot towards increased adaptability, efficiency, and sustainable practices, echoing the principles of Industry 4.0. By realigning business operations with digital initiatives, IVECO aims to not only improve production capabilities but also align with global environmental goals. This journey, steered by strategic implementations, underscores a commitment to harness technological advancements for bolstering competitive strength.

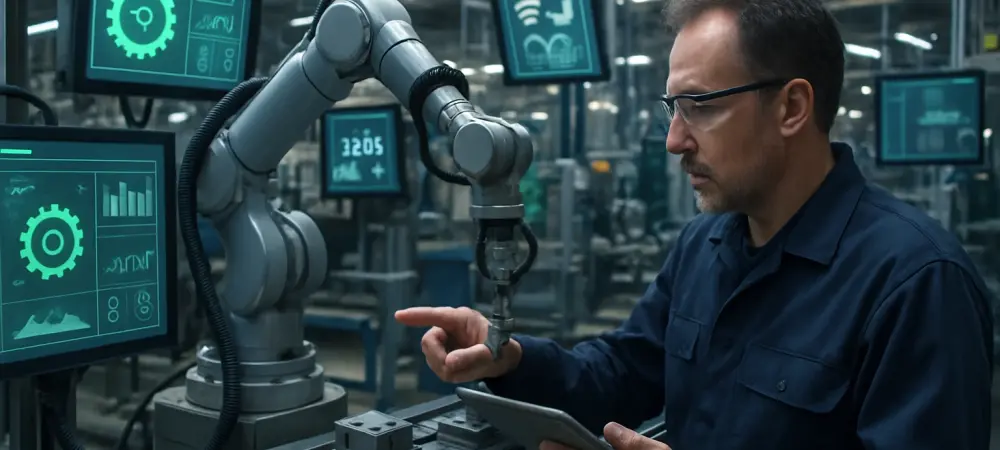

Discovering the Power of the I3OT Platform

Central to IVECO’s digital transformation is the innovative I3OT platform. This cutting-edge system connects disparate production sites through an edge-to-cloud architecture, optimizing data flow from sensors to central processing units. By localizing data management, the platform minimizes cloud dependency, focusing on critical insights pivotal for informed decision-making. Through this intelligent integration, IVECO achieves notable advancements in operational efficiency, paving the way for more agile and responsive manufacturing processes.

Insightful Perspectives from Industry Leaders

Industry aficionados have frequently vouched for the transformative potential inherent in IoT. A recent publication highlighted, ” IoT’s integration has consistently showcased 60% improvements in operational workflows.” Operational leaders within IVECO have shared anecdotes of how the I3OT platform has catalyzed enhancements in real-time decision-making, ensuring dynamic production adaptability. These narratives echo broader industry sentiments that endorse AI’s role in revolutionizing data access and stakeholder engagement.

Embracing IoT’s Practical Applications

Increased use of IoT beckons manufacturers to rethink operational methods. Strategic integration of solutions like I3OT can fundamentally improve production strategies, achieving scalability and sustainability. Specifically, organizations eyeing digital transformation should focus on developing interoperable systems, fostering a culture receptive to innovative technologies. By prioritizing investment in IoT infrastructure, companies can ensure a seamless transition to smarter production landscapes.

Reflecting on Future Directions

IVECO’s commitment has firmly established a foundation for future growth and adaptation in the dynamic world of industrial manufacturing. The steps taken have provided a framework for embracing sustainable practices and incorporating intelligent solutions. As IoT continues to explore new frontiers, IVECO’s journey may offer invaluable insights for other industry players. This evolution not only underscores the importance of technology in modern manufacturing but also highlights a pathway to enduring industrial success.