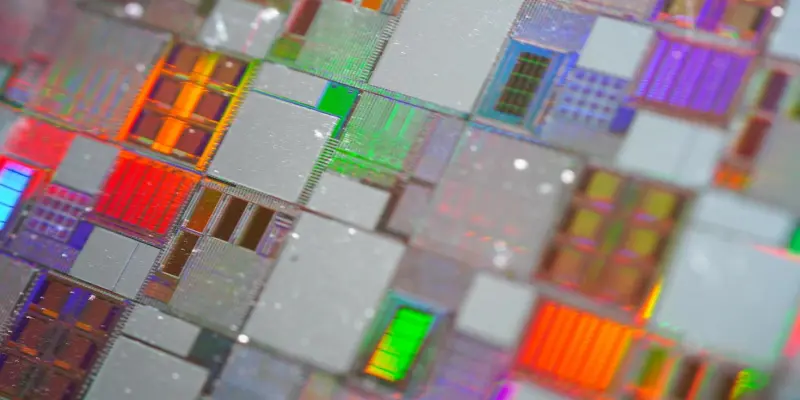

Amid rapid advancements in technology, Huawei’s decision to construct a “mega chip facility” in Shenzhen is garnering significant attention. This marks Huawei’s strategic pivot as it transitions from a primarily mobile-centric company to a robust entity in the artificial intelligence sector. The facility is pivotal in producing the company’s high-demand Kirin and Ascend AI chips. These chips are crucial for the advancement of AI capabilities, enabling Huawei to compete with industry stalwarts such as NVIDIA. This initiative reflects Huawei’s ambition to solidify its place in the upper echelons of the semiconductor industry. Through this facility, Huawei aims to alleviate the current production bottleneck it faces, particularly concerning the production of larger 7nm chips. This development is crucial as Huawei looks to address soaring demands in the market.

Moving Towards Vertical Integration

Huawei’s new facility isn’t merely a boost to their manufacturing capabilities; it signifies a broader strategic goal. By advancing this establishment, Huawei emphasizes a commitment to a vertically integrated AI supply chain, aiming for resilience and independence amid global tech tensions. The site’s proximity to Chinese foundries facilitates quicker sourcing and collaboration within Huawei’s supply network, enhancing efficiency. Although not directly involved in daily operations, Huawei entrusts companies like SiCarrier and SwaySure to manage tasks while Huawei focuses on strategic funding and oversight. This enables Huawei to sidestep operational risks while ensuring strategic goals are pursued. Recognizing the project’s national importance, the local government supports Huawei, aligning its initiatives with China’s semiconductor ambitions. This alliance is vital given SMIC’s challenges in meeting industry demands. Launching next year, this facility will be pivotal for Huawei’s sustainable chip technology aspirations, reinforcing both Huawei’s and China’s place in the global tech arena.