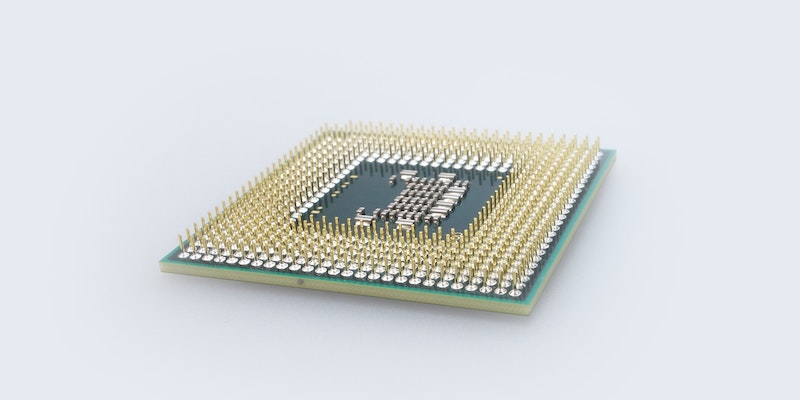

In a remarkable technological breakthrough, Intel has revealed its next-gen Glass Substrate packaging technology, poised to revolutionize the industry by replacing existing organic materials and offering higher interconnects. This cutting-edge advancement promises to enable rapid large-scale innovations across various industries.

Importance of Glass Substrates

Intel firmly believes that “glass substrates” hold the key to the future of chip packaging. With the introduction of this new packaging technology, the possibilities for advancements in industries such as high-performance computing and artificial intelligence are endless. The integration of glass substrates is expected to bring about significant improvements and drive efficiencies across multiple sectors.

Intel’s achievements include

After a decade of extensive research and development, Intel has successfully achieved industry-leading glass substrates for advanced packaging. This remarkable milestone underscores the company’s commitment to pushing the boundaries of chip packaging technology and driving innovation forward.

Benefits of glass substrates

One of the critical factors that determines the superiority of a chip packaging technology is its capacity to integrate numerous “chiplets” in a single package. With the introduction of glass substrates, Intel discloses that manufacturers can now feature larger chiplet complexes. This advancement allows for a reduction in the footprint of a single package, leading to improved efficiency and a significant performance boost.

Enhanced features of glass substrates

The utilization of glass substrates brings forth notable enhancements to the overall chip packaging design. The substrates boast a more considerable temperature tolerance and a flatter design, contributing to enhanced interlayer connectivity. This improved connectivity ensures seamless power delivery and facilitates data transmission, thus optimizing the performance of the chips.

Intel states that the glass substrates exhibit a phenomenal 10x increase in interconnect density compared to previous packaging technologies. This increase in density contributes to improved power efficiency and paves the way for more robust computing capabilities.

Future release and goals

While Intel has not specified a release date for glass substrates, the company’s unveiling brings them one step closer to their ambitious goal of achieving “1 billion transistors” in a single package by 2030. This roadmap sets the stage for other advancements and technological breakthroughs that Intel aims to bring about in the coming years.

Impact on a specific industry

The significance of glass substrates is expected to have the most substantial impact in the high-performance computing and artificial intelligence industries. The integration of glass substrates will enable these sectors to leverage enhanced computing power, facilitating complex tasks and fueling breakthroughs in these rapidly evolving fields.

Adoption of the standard

While the unveiling of glass substrates marks a significant achievement in chip packaging technology, the next crucial step is the widespread adoption of the standard. Industry experts anticipate that this adoption will occur within the coming years as more manufacturers recognize the potential benefits and advantages that glass substrates offer.

In conclusion, Intel’s next-gen Glass Substrate packaging technology brings forth a new era in chip packaging, replacing traditional materials and offering higher interconnects. With a decade of research backing their achievements, Intel stands at the forefront of this innovation. Glass substrates open up a world of possibilities for various industries, particularly high-performance computing and artificial intelligence. As Intel continues on its path to achieving its goal of “1 billion transistors” in a single package by 2030, the impact and benefits of glass substrates are set to reshape the future of chip packaging technology.