Building complex materials in orbit is rapidly transforming from science fiction into a tangible industrial reality, representing a significant advancement for the advanced materials and aerospace sectors. This review explores the technology’s evolution, core features, and disruptive potential for high-tech applications, focusing on recent breakthroughs by the startup Space Forge to provide an understanding of its current capabilities.

The Dawn of Orbital Factories

In-space manufacturing harnesses the unique environmental conditions of orbit—specifically microgravity and a hard vacuum—to create materials with properties impossible to replicate on Earth. As terrestrial manufacturing approaches its physical limits, the technology is gaining relevance.

Leading this charge is Space Forge, a Cardiff-based innovator pushing the boundaries of what can be built in orbit. Their work exemplifies the shift toward leveraging space not just for observation, but as a pristine environment for industrial production.

Core Technologies and the Advantages of Orbit

The Microgravity Advantage for Crystalline Perfection

The absence of gravity is a primary advantage of orbital manufacturing. On Earth, forces like convection and sedimentation disrupt the formation of uniform crystalline structures. In microgravity, these disturbances are eliminated, allowing atoms to arrange into near-perfect lattices.

For semiconductors, this structural uniformity is paramount. A more perfect crystal lattice translates directly to enhanced electronic efficiency and integrity, promising a generational leap in component performance.

Leveraging the Ultimate Vacuum for Purity

Complementing microgravity is the near-perfect vacuum of space, an environment far cleaner than any terrestrial cleanroom. This pristine setting eliminates atmospheric contaminants that degrade the performance of sensitive materials. This is critical for producing materials with unparalleled purity, potentially thousands of times greater than Earth-made counterparts. This enables materials to handle higher power and operate more efficiently.

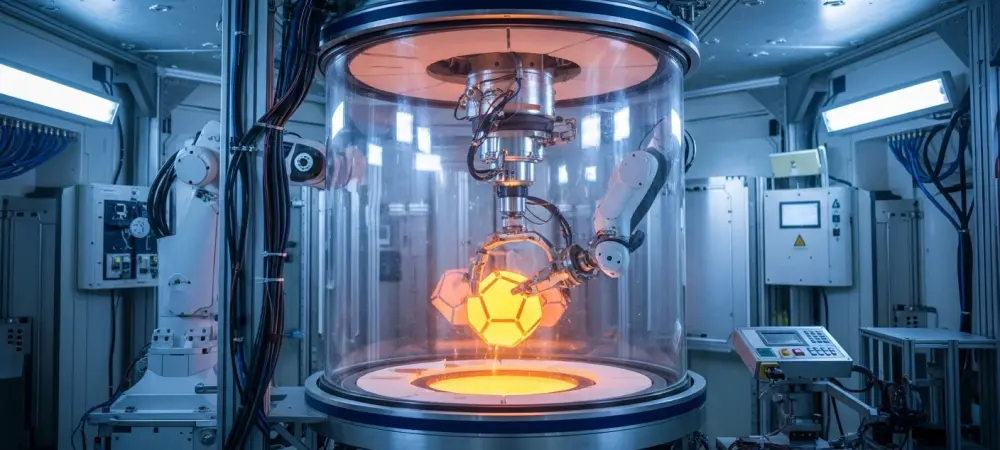

The Orbital Furnace A Contained Production System

The foundational technology from Space Forge is a compact, microwave-sized orbital factory with a high-temperature furnace. This self-contained system creates and sustains the stable plasma conditions needed for advanced materials processing in space.

Its validation is the technological bedrock for larger in-space foundries. This success transforms the orbital factory from a concept into a proven, functional system ready for scaling.

Recent Milestones and In-Orbit Validation

The transition of in-space manufacturing from theory to reality was marked by a recent in-orbit test where Space Forge’s furnace reached nearly 1,000°C. This achievement validates the platform’s core functionality. This milestone confirms that the precise, high-temperature environment for semiconductor fabrication can be reliably created in orbit, providing the proof-of-concept needed for commercial-scale production.

High-Impact Applications of Space-Made Materials

The ultra-pure materials from orbit are targeted at critical industries. The superior performance of space-made semiconductors is poised to impact next-generation 5G infrastructure, where signal clarity is key.

These materials will also drive innovation in electric vehicle systems by enabling more efficient power conversion. The aerospace sector also stands to benefit from more resilient and capable components.

Overcoming Hurdles The Challenge of Re-entry

A significant hurdle remains: safely returning finished products to Earth. The intense heat of atmospheric re-entry can damage these high-value materials, a primary barrier to commercial viability. Space Forge is developing the “Pridwen” heat shield to address this, a technology engineered to protect delicate cargo during descent. Pridwen’s success is the final, essential link in the supply chain.

The Future Outlook for Orbital Foundries

With the core technology validated, the focus is shifting toward scalability and diversification. Space Forge plans a larger orbital foundry to move from demonstration to commercial operation. Future applications could extend beyond semiconductors to pharmaceuticals and biological tissues. These breakthroughs could herald a new era of off-world industry that transforms life on Earth.

Conclusion A New Industrial Frontier

The successful demonstration of core manufacturing technologies in orbit marked a definitive shift for in-space production, moving it from a theoretical possibility to a practical and emerging industry. The unique environmental advantages of microgravity and vacuum offer a clear pathway to creating materials with a perfection and purity unattainable on Earth. While challenges like atmospheric re-entry are still being addressed, the foundational principles were proven, signaling the dawn of a new industrial frontier where orbital foundries could become a cornerstone of advanced technology and a novel, space-based economy.