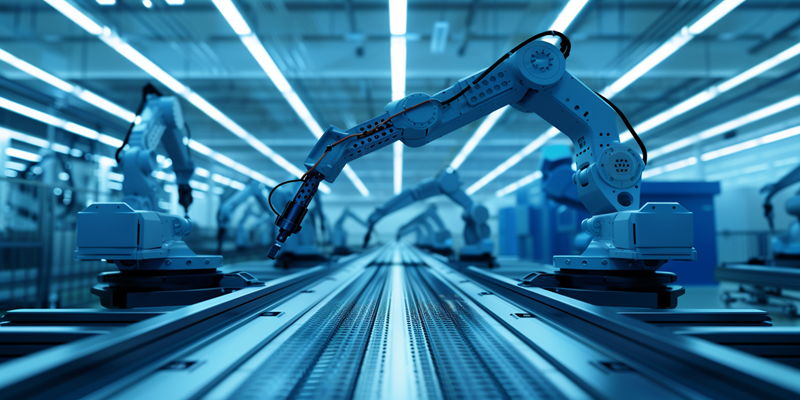

The manufacturing industry has always been at the forefront of adopting new technologies to enhance productivity and efficiency. From the introduction of the first industrial robot, Unimate, at a General Motors plant in 1962, to the advent of collaborative robots and autonomous mobile robots, technological advancements have consistently revolutionized production processes. Now, with the integration of artificial intelligence (AI) into robotics, the industry is poised for another transformative leap. This integration is set to bring unparalleled flexibility, efficiency, and innovation, but it also presents unique challenges that must be navigated effectively.

The Evolution of Robotics

Robotics in manufacturing began with straightforward automation tasks, which significantly increased efficiency by taking over repetitive, high-volume jobs from human workers. The initial deployment of Unimate was a drastic shift in how manufacturing was approached. Over the decades, robots have evolved from performing simple, repetitive tasks to more complex activities, yet most traditional robots have limitations when dealing with low-volume, highly variable productions.

One of the key advancements in the evolution of robotics is the development of collaborative robots, or “cobots.” These robots are designed to work alongside human workers, sharing tasks in a manner that leverages the strengths of both human dexterity and robotic precision. Another significant development is autonomous mobile robots (AMRs), which are capable of navigating dynamic environments without direct human intervention. Both cobots and AMRs are enhanced by the incorporation of AI, allowing them to adapt to complex, real-world scenarios that were once beyond their capabilities.

The adoption of these AI-enhanced robots has driven a surge in productivity and efficiency in manufacturing plants around the world. Cobots and AMRs not only improve the precision and speed of production processes but also enhance safety by taking over potentially hazardous tasks. These advancements signify a shift from robots merely performing tasks to becoming integral components of the manufacturing ecosystem. The continual evolution of robotics, combined with AI, promises even more significant innovations, reducing the gap between human abilities and machine execution.

The Impact of AI on Robotics

AI integration marks a pivotal shift for robotics in manufacturing. AI algorithms, particularly those involving deep learning, enable robots to analyze high-resolution images and make decisions based on real-time data. This capability is critical for applications such as quality control, where robots can detect and remove defective items from production lines with unprecedented accuracy and speed.

These advancements mean that AI-powered robots can handle tasks that involve a degree of variability and uncertainty which traditional robots couldn’t manage efficiently. For example, in environments where products are unique or customized, AI allows robots to adjust their operations dynamically, without needing extensive reprogramming for each new task. This flexibility makes AI-integrated robotics a game-changer for industries that deal with a high mix of low-volume products.

Moreover, AI-driven improvements extend beyond real-time decision-making. Predictive maintenance is another significant benefit, where AI algorithms monitor and predict the operational health of machinery, thus avoiding unexpected downtimes. By anticipating failures before they occur, AI-enhanced robots can ensure that production lines run smoothly and efficiently. The result is a more resilient manufacturing setup, capable of adapting to the demands of modern production requirements and maintaining high quality and consistency across the board.

Overcoming Adoption Challenges

Despite the promising advancements, several challenges must be addressed to fully capitalize on the potential of AI-integrated robotics. One significant hurdle is the skills gap in the workforce. There is a pressing need for workers who are not only adept in traditional manufacturing processes but also possess a solid understanding of AI and advanced robotics. This dual expertise is currently scarce, necessitating comprehensive training and education programs to bridge this gap.

Another challenge is the “black box” nature of AI. Many AI systems can make decisions without clear, interpretable reasoning processes. This opacity can make it difficult for manufacturers to trust AI-driven recommendations, particularly for critical tasks. Ensuring transparency and developing methodologies to interpret and validate AI decisions are crucial for broader adoption in the manufacturing sector.

Additionally, the costs associated with implementing AI-integrated robotics can be prohibitive, particularly for smaller manufacturers operating on tighter budgets. Investing in advanced machinery and training programs requires significant upfront capital, something not every company can readily afford. However, fostering partnerships with technology providers, seeking government grants, and exploring financing options can help mitigate these financial barriers. Companies must strategically plan their investments to ensure that the long-term benefits far outweigh the initial expenditures.

Leadership and Organizational Change

Successful integration of AI into industrial robotics requires not just technological changes but also significant shifts in leadership and organizational culture. It is essential for high-level business leaders to understand the potential benefits and be willing to champion the required changes. This involves restructuring workflows and processes, as well as empowering employees who are well-versed in technology.

Leaders need to foster an environment that values quick learning, adaptability, and collaboration. These are critical traits for identifying the most valuable applications of AI and robotics and for iterating rapidly to optimize their implementation. Promoting a culture of continuous improvement and innovation will help companies stay ahead in a rapidly evolving technological landscape.

Furthermore, executives must prioritize aligning technological adoption with broader business strategies. This alignment ensures that AI and robotics deployments directly contribute to achieving organizational goals, whether it’s enhancing product quality, improving speed to market, or increasing operational efficiency. By embedding technological initiatives within the strategic framework, companies can maximize the return on investment and drive sustained growth.

Successful leaders in this transformation will need to build cross-functional teams that combine expertise from various domains, including IT, manufacturing, data science, and operations. These interdisciplinary teams can work collaboratively to develop and implement AI-integrated robotic solutions that address specific manufacturing challenges. Encouraging open communication and knowledge sharing across departments will be vital in creating a unified approach to technology adoption and overcoming any resistance to change within the organization.

The Future Landscape of Manufacturing

The manufacturing sector has long been a leader in embracing new technologies to boost productivity and efficiency. Starting with the deployment of the first industrial robot, Unimate, at a General Motors plant in 1962, to the emergence of collaborative robots and autonomous mobile robots, technological innovation has consistently revolutionized production processes. The latest wave of innovation involves the integration of artificial intelligence (AI) into robotics, setting the stage for another significant transformation. This integration promises unprecedented flexibility, efficiency, and creativity. AI-driven robots are expected to streamline operations, optimize supply chains, and enable more complex manufacturing tasks. However, this advancement also comes with unique challenges, such as the need for advanced cybersecurity measures to protect against potential threats and the necessity for ongoing education and training for the workforce to adapt to these new technologies effectively. Properly navigating these challenges will be crucial for maximizing the benefits of AI in the manufacturing industry.