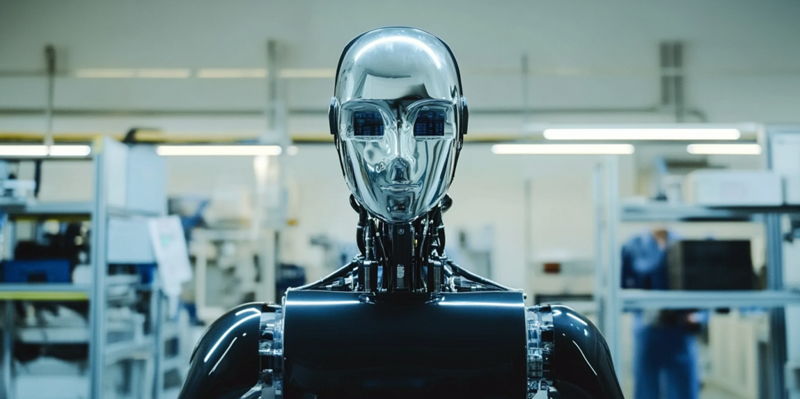

The manufacturing industry has long been a cornerstone of economic development, driving innovation and productivity. In recent years, the integration of robotics and Artificial Intelligence (AI) has brought about transformative changes, pushing the boundaries of what is possible in manufacturing. This article delves into the profound impact of these technologies, exploring their current applications, future potential, and the challenges that come with their adoption.

The Current State of Robotics in Manufacturing

Evolution of Robotics Technology

Over the past several decades, robotics technology has undergone immense evolution, moving from basic automated machines to sophisticated systems capable of multitasking and learning. The introduction of six-axis arms, delta robots, and gantry systems marked the beginning of this transformation, allowing for precise, repetitive movements and tasks. More recent advancements like autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) have expanded the scope of automation, enabling the movement of goods and management of inventory with minimal human intervention. These technologies have dramatically increased productivity by taking over labor-intensive roles.

With these advancements, workers are no longer confined to monotonous and repetitive tasks. They are now engaged in more intellectually demanding roles that require problem-solving, critical thinking, and creativity. Consequently, the role of human workers has shifted, enhancing job satisfaction and opening new opportunities for growth and professional development. However, this positive shift has not come without challenges. Workers need to be upskilled or reskilled to adapt to the new technological landscape, and companies must invest in continuous learning and development programs to ensure their workforce remains competitive and capable.

Impact on Workforce Dynamics

The shift from manual labor to automation has significantly altered the workforce dynamics in the manufacturing industry. As robotics takes on repetitive and hazardous tasks, employees have the chance to focus on more meaningful and engaging work, such as oversight and strategic management. This transition not only improves job satisfaction but also promotes a healthier work environment by reducing the risk of injuries and stress associated with repetitive tasks.

Moreover, the demand for skilled technicians and engineers to maintain and program these advanced machines has surged, leading to new career opportunities and roles within the sector. Upskilling and reskilling initiatives are crucial in this context, ensuring that the current workforce can transition smoothly into these new roles without facing obsolescence. Organizations must therefore implement comprehensive training programs that can help their employees adapt to the rapidly changing technological environment, thus fostering a culture of continuous learning and innovation.

The Role of Robotic Process Automation (RPA)

Enhancing Efficiency and Accuracy

Robotic Process Automation (RPA) has become an invaluable asset in the manufacturing sector, providing substantial improvements in efficiency and accuracy. By automating routine and repetitive tasks, RPA reduces the likelihood of human error, ensuring a consistent and high-quality output. This technology is especially beneficial in areas like inventory management, quality control, and supply chain operations, where reliability and precision are paramount.

By automating these critical functions, RPA frees up human workers to concentrate on more strategic and high-value tasks, such as optimizing production processes and developing innovative solutions. This broader application of RPA not only streamlines operations but also enhances overall productivity. With the advent of advanced RPA systems, manufacturers can now handle intricate tasks that require meticulous attention to detail, further minimizing errors and inefficiencies.

Integration with Existing Systems

One of the standout features of RPA is its seamless integration with existing systems, allowing manufacturers to enhance their current infrastructure without major disruptions. This compatibility means that enterprises can leverage advanced automation solutions while maintaining the functionalities of their established processes. As a result, the transition to a more automated environment is smoother and less daunting, enabling continuous improvement and innovation.

Manufacturers can thus implement RPA incrementally, testing and refining its application before expanding its scope across the production floor. This methodical approach ensures that any potential issues can be addressed promptly, minimizing risks and maximizing benefits. By adopting RPA, manufacturers are empowered to drive significant advancements in process efficiency and operational agility, allowing them to stay competitive in an increasingly automated and data-driven landscape.

The Synergy Between Robotics and AI

Combining Strengths for Greater Impact

The synergy between robotics and AI is creating unprecedented advancements in the manufacturing industry, harnessing the strengths of each technology to deliver superior results. While robotics excels in performing physical tasks with unmatched precision, AI introduces cognitive capabilities that enable machines to learn from experience, adapt to new situations, and make informed decisions. This powerful combination results in a substantial impact that surpasses the benefits of either technology used in isolation.

For instance, robots equipped with AI can carry out complex assembly tasks that require adaptability and fine motor skills, while also analyzing data in real-time to optimize performance and reduce waste. This integration fosters a more agile and efficient manufacturing process, capable of responding swiftly to changing demands and market conditions. As AI continues to advance, its ability to augment robotic capabilities will only grow, driving further innovations in the field.

Real-Time Data and Predictive Analytics

AI-powered systems are revolutionizing manufacturing by providing real-time data analysis and predictive analytics, which enhance decision-making and operational efficiency. These systems can process vast amounts of data quickly, identifying patterns and trends that humans might overlook. Predictive analytics, in particular, is a game-changer for maintenance and repair operations, allowing for the early detection of potential equipment failures before they cause significant downtime.

By leveraging these insights, manufacturers can implement proactive maintenance strategies, extending the lifespan of their machinery and reducing operational disruptions. This real-time oversight enables more informed decisions, driving optimizations across various facets of the manufacturing process and leading to substantial cost savings. As AI technology continues to evolve, its integration with robotics will further enhance these capabilities, pushing the boundaries of what is possible in manufacturing.

The Potential of Generative AI in Manufacturing

Transforming Knowledge Work

Generative AI (GenAI) is poised to bring transformative changes to knowledge work within the manufacturing sector. By integrating comprehensive knowledge bases with real-time data, these systems empower workers to access and utilize information more effectively, significantly improving the speed and accuracy of decision-making. Maintenance workers, for example, can employ GenAI to quickly diagnose complex issues by correlating data points that would have taken years to identify manually.

The capabilities of GenAI extend beyond simple diagnostics. It allows for the automation of knowledge-intensive tasks, such as planning and optimization, thereby enabling more efficient use of resources and reducing slack time. By assisting workers in this manner, GenAI augments human abilities, leading to faster response times and higher quality outcomes. This transformation underscores the pivotal role that AI will play in reshaping the future of manufacturing knowledge work.

Enhancing Troubleshooting and Optimization

Automation technicians stand to benefit immensely from GenAI tools that simplify troubleshooting and optimization tasks. Traditional methods of diagnosing system logic and identifying root causes can be time-consuming and prone to errors. GenAI, however, leverages advanced algorithms to analyze complex datasets and pinpoint issues with remarkable precision. This capability accelerates problem-solving and enhances the overall efficiency of manufacturing operations.

As GenAI systems mature, their impact on productivity and quality will become even more pronounced. For instance, they can be used to monitor real-time production metrics, adjusting processes on the fly to maintain optimal performance. This dynamic approach enables manufacturers to achieve higher levels of efficiency while maintaining stringent quality standards. By embracing GenAI, the manufacturing industry can unlock new potential, driving significant advancements in operational effectiveness and innovation.

Investment and Adoption Trends

Increasing Investment in AI and Automation

Across the manufacturing industry, there is a growing trend of investing heavily in AI and automation technologies. Recent reports indicate that a significant percentage of manufacturing enterprises plan to incorporate GenAI into their operations by 2024, reflecting a widespread recognition of the value these technologies bring in terms of efficiency, quality, and innovation. This investment trend signals a commitment to staying competitive in an ever-evolving technological landscape.

Manufacturers are also exploring various avenues to integrate AI and automation across their operations, from enhancing supply chain logistics to improving customer service through intelligent chatbots. These investments are aimed at driving not just incremental improvements but also transformational changes that can redefine industry standards and practices. By staying ahead of the curve in adopting AI and automation, manufacturers position themselves to be leaders in the market, capable of delivering superior products and services.

Workforce Expansion and Cybersecurity Challenges

Despite widespread concerns about job displacement due to increased automation, research shows that the majority of manufacturers actually plan to expand their workforce in tandem with digitization efforts. However, this shift toward digital integration brings its own set of challenges, particularly in the realm of cybersecurity. With a significant portion of cyber-attacks targeting industrial organizations, there is an urgent need for enhanced security measures to protect against threats.

Converged Information Technology / Operational Technology (IT/OT) systems are especially vulnerable to cyber-attacks, making robust cybersecurity protocols indispensable. Manufacturers must invest in advanced cybersecurity solutions to safeguard their operations, ensuring the secure deployment of AI and automation technologies. By addressing these challenges head-on, the manufacturing sector can fully harness the benefits of digital transformation while maintaining a secure and resilient operational environment.

The Future of Manufacturing

Digital Workers and Human Collaboration

Looking forward, the future of manufacturing will be characterized by seamless collaboration between digital workers and human employees. Digital workers, powered by AI, will significantly aid human counterparts in tasks such as troubleshooting code and managing alarms, thereby amplifying human capabilities and boosting operational efficiency. This hybrid approach leverages the strengths of both humans and machines, leading to innovations that would be unattainable by either alone.

As AI technology continues to evolve, we can anticipate a rise in the complexity and scope of tasks that digital workers can perform. This will include more advanced forms of predictive maintenance, adaptive supply chain management, and real-time quality control, ensuring that manufacturing processes remain cutting-edge and highly efficient. The synergy between AI-driven automation and human ingenuity will drive the industry towards unprecedented levels of productivity and insight.

Embracing Technological Innovations

The manufacturing industry has been a crucial part of economic growth, spurring innovation and productivity. Recently, the introduction of robotics and Artificial Intelligence (AI) has led to significant changes, expanding the possibilities within the manufacturing sector. This development is profoundly influencing various aspects of manufacturing, from enhancing efficiency to improving precision in production processes.

Robotics has automated many repetitive and hazardous tasks, reducing human error and workplace injuries while increasing speed and accuracy. AI complements this by optimizing supply chain management, predicting maintenance needs, and enhancing product quality through advanced data analytics. Together, these technologies are revolutionizing the way products are designed, produced, and delivered.

However, the adoption of robotics and AI is not without its challenges. Companies must address issues related to cybersecurity, the need for specialized workforce training, and the potential displacement of jobs. Despite these hurdles, the future of manufacturing looks bright with the potential these technologies hold. As they continue to evolve, robotics and AI will likely further redefine the industry’s landscape, driving it towards unprecedented growth and efficiency.