Unleashing a New Era of Industrial Innovation with 5G

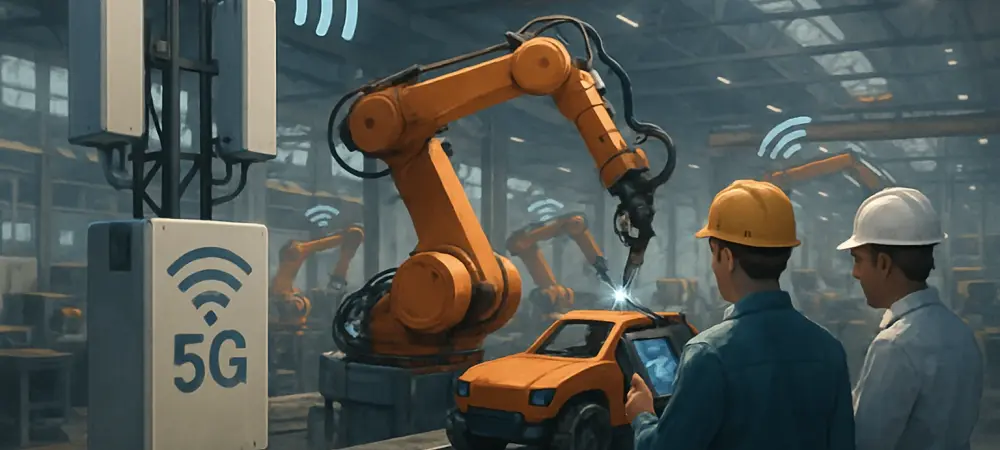

The manufacturing sector stands at a pivotal moment where connectivity can redefine the boundaries of efficiency and innovation, transforming the way factories operate on a global scale. Picture a sprawling factory floor where machines communicate seamlessly, robots adjust to production changes in real time, and managers oversee operations from halfway across the globe without a glitch. This is the promise of 5G technology—a game-changer that delivers unprecedented speed, ultra-low latency, and reliable wireless networks. As a cornerstone of Industry 4.0, 5G is transforming industrial operations by enabling smart factories that operate with heightened productivity, enhanced safety, and remarkable cost savings.

This guide aims to explore how 5G is reshaping manufacturing, offering a detailed look into its potential to overhaul traditional processes. From automation to real-time data processing, the impact of this technology spans multiple facets of the industry, paving the way for a digital revolution. Readers will gain insights into specific transformations and practical steps to leverage 5G for competitive advantage.

The importance of understanding 5G’s role cannot be overstated, as it equips manufacturers with tools to meet modern demands and stay ahead in a rapidly evolving market. This exploration will cover key areas such as intelligent automation, flexible production systems, and enhanced monitoring, providing a roadmap for integrating cutting-edge connectivity into industrial environments. By delving into these topics, the guide sets the stage for actionable strategies that can drive significant operational improvements.

The Backbone of Industry 4.0: Why 5G Matters

At the heart of the fourth industrial revolution lies 5G, a technology often likened to a high-speed nervous system for manufacturing ecosystems. It connects the physical elements of a factory—machines, sensors, and equipment—with digital solutions like artificial intelligence and advanced analytics. This seamless integration is vital for achieving the real-time control and data-driven decision-making that define smart manufacturing, making 5G an indispensable asset for modern industrial setups.

The significance of 5G extends beyond mere connectivity; it acts as an enabler for predictive maintenance, where potential equipment failures are identified and addressed before they disrupt operations. Industry experts emphasize that without such robust wireless networks, the full potential of intelligent automation remains untapped. The technology’s ability to handle vast data volumes with minimal delay positions it as a critical component in creating responsive and adaptive production environments.

Adopting 5G is not just a trend but a strategic necessity in today’s competitive landscape. Insights from thought leaders highlight the urgency of embracing this technology to maintain market relevance. As manufacturing continues to digitize, 5G provides the infrastructure needed to support complex systems, ensuring that companies can innovate and scale efficiently while meeting the growing expectations of precision and speed.

Key Transformations: How 5G Is Redefining Manufacturing Processes

Transformation 1: Enabling Real-Time Data Processing and Decision-Making

Bridging Data to Action

One of the most profound impacts of 5G in manufacturing is its capacity to process data in real time, turning raw information into actionable insights almost instantly. With the ability to connect thousands of devices and sensors across a factory floor, this technology ensures that data flows without interruption. Manufacturers can monitor production metrics continuously, allowing for immediate adjustments that boost productivity and minimize inefficiencies.

The integration of artificial intelligence with 5G further enhances this capability by analyzing data at the edge, reducing dependency on distant cloud servers. This means decisions about machine performance or resource allocation happen in a fraction of a second, directly impacting operational efficiency. Such speed is crucial in high-stakes environments where even minor delays can lead to significant losses.

Real-World Applications in Mining and Beyond

Practical examples of 5G’s impact are evident in industries like mining, where private 5G networks support automated vehicles for safer and more efficient operations. These networks enable real-time communication between equipment, ensuring that hazards are identified and mitigated promptly. Beyond mining, factories producing consumer goods also benefit from this technology by optimizing workflows through instant data feedback.

This transformation is not limited to specific sectors but applies broadly across manufacturing, where safety and precision are paramount. The ability to act on data as it is generated creates a ripple effect, enhancing not just individual processes but the entire production chain. As a result, companies adopting 5G see marked improvements in both output quality and workplace safety.

Transformation 2: Driving Flexibility in Production Environments

Simplifying Network Architecture

Another significant shift brought by 5G is the simplification of network infrastructure within manufacturing facilities. Traditional setups often rely on multiple Wi-Fi access points and extensive cabling, which can be cumbersome and energy-intensive. In contrast, 5G replaces these with single cellular antennas, streamlining connectivity while reducing power consumption significantly.

This architectural overhaul allows for greater flexibility in configuring production lines, as equipment can be moved or reorganized without the constraints of wired connections. Such adaptability is essential for manufacturers aiming to respond swiftly to market changes or customize output based on demand. The reduced need for physical infrastructure also translates into lower maintenance costs over time.

Supporting Sustainable Practices

Beyond operational benefits, 5G contributes to environmental sustainability by minimizing the reliance on copper cabling and complex control systems. This reduction in physical resources aligns with broader goals of reducing carbon footprints in industrial operations. Factories can achieve greener practices without sacrificing performance, a balance that is increasingly critical in regulatory landscapes.

The environmental impact of adopting 5G extends to energy efficiency, as streamlined networks consume less power for cooling and operation. Manufacturers committed to sustainable growth find in 5G a tool that supports both ecological and economic objectives. This dual advantage underscores the technology’s role in shaping a more responsible industrial future.

Transformation 3: Powering Automation and Smart Manufacturing

Scaling Robotics with Reliable Networks

Automation stands as a pillar of modern manufacturing, and 5G is the key to unlocking its full potential through reliable wireless connectivity. Autonomous robots and automated guided vehicles depend on instantaneous communication to coordinate tasks effectively. With 5G, these tools operate without the lag or security risks that previously limited their deployment in critical areas.

This robust network support allows manufacturers to scale automation across diverse functions, from assembly to logistics, with confidence in consistent performance. Overcoming security concerns also paves the way for broader adoption of artificial intelligence in managing robotic systems, enhancing precision in discrete manufacturing tasks. The result is a factory floor that operates with minimal human intervention yet maximum accuracy.

Building Scalable Ecosystems

The convergence of robotics, artificial intelligence, and the Internet of Things under a 5G framework creates scalable ecosystems capable of adapting to complex demands. These ecosystems enable fully automated environments where systems learn and optimize processes independently. Such responsiveness is vital for handling fluctuating production needs or integrating new technologies seamlessly.

Manufacturers benefit from a unified platform where data from various sources integrates to inform automation strategies. This interconnected approach not only boosts efficiency but also fosters innovation by allowing for rapid testing and deployment of new solutions. As a result, 5G-driven ecosystems position companies to lead in smart manufacturing advancements.

Transformation 4: Enhancing Equipment Monitoring and Supply Chain Visibility

Boosting Equipment Effectiveness

Effective equipment monitoring is essential for maintaining uptime and ensuring smooth operations, and 5G offers unparalleled support in this area. Its high-speed connectivity enables real-time tracking of machinery performance, identifying issues before they escalate into costly downtime. Manufacturers can respond to operational changes swiftly, keeping production on track.

This level of oversight, supported by data-intensive networks, enhances overall equipment effectiveness by minimizing unexpected failures. Detailed analytics provide insights into wear and tear, guiding maintenance schedules with precision. Consequently, factories achieve higher reliability and longevity from their assets, directly impacting profitability.

Empowering Collaboration with Visual Tools

Supply chain visibility also sees a significant boost with 5G, as it facilitates the use of visual and remote collaborative tools across distributed operations. Managers can access live feeds or detailed reports from any location, ensuring transparency in logistics and inventory management. This capability is crucial for coordinating with suppliers and partners in real time.

Such tools enable a collaborative approach to problem-solving, where teams address supply chain disruptions collectively, even from afar. The robust connectivity of 5G ensures that data-heavy applications run smoothly, maintaining performance standards regardless of geographic barriers. This fosters a more cohesive and agile supply network, vital for meeting customer expectations.

Transformation 5: Supporting AR/VR for Remote Operations

Facilitating Lag-Free Data Streaming

Augmented reality (AR) and virtual reality (VR) are transforming how manufacturers approach training and remote assistance, and 5G’s low latency makes this possible. By supporting massive IoT integration, the technology ensures lag-free streaming of sensor data for instant AI-driven insights through AR/VR platforms. Operators can visualize complex processes or simulate scenarios without delays.

This capability enhances training programs by providing immersive experiences that replicate real-world conditions safely. Remote experts can guide on-site staff through intricate repairs using AR overlays, improving accuracy and reducing errors. The seamless data flow enabled by 5G turns these tools into practical solutions for everyday industrial challenges.

Connecting Remote and Hazardous Sites

In remote or hazardous locations where traditional infrastructure is scarce, 5G proves invaluable by enabling virtual monitoring and troubleshooting. Sites lacking fiber connectivity can still access high-speed networks, allowing for real-time oversight of operations in challenging environments. This connectivity ensures that safety protocols are upheld even in isolated areas.

Manufacturers operating in such conditions benefit from continuous data access, which supports decision-making without the need for physical presence. Virtual inspections and audits conducted via 5G reduce risks to personnel while maintaining operational standards. This application of technology bridges significant logistical gaps, enhancing overall site management.

Summarizing the Impact: Core Benefits of 5G in Manufacturing

The transformative power of 5G in manufacturing crystallizes into several core benefits that redefine industrial capabilities. These advantages span various operational dimensions, collectively driving efficiency and positioning companies for sustained success. A clear understanding of these benefits highlights why 5G adoption is a strategic imperative for forward-thinking manufacturers.

- Real-time data processing for faster decision-making, ensuring immediate responses to production variables.

- Enhanced flexibility through simplified, wireless networks that adapt to changing operational needs.

- Scalable automation with reliable connectivity, supporting advanced robotics and smart systems.

- Improved equipment uptime and supply chain transparency, optimizing performance across the board.

- Advanced remote operations via AR/VR technologies, enabling effective management from any location.

These benefits underscore how 5G serves as a catalyst for cost reduction and innovation. By integrating this technology, manufacturers achieve a competitive edge through streamlined processes and enhanced responsiveness. The collective impact of these advantages shapes an industry that is not only more efficient but also better equipped to handle future challenges.

Looking Ahead: 5G’s Role in Future Industrial Trends and Challenges

As manufacturing continues to evolve, 5G stands poised to play a central role in shaping emerging trends and addressing persistent challenges. Its integration with technologies like edge computing and the Internet of Things promises fully autonomous industrial environments where decisions occur with minimal human input. This trajectory points toward factories that operate with unparalleled intelligence and adaptability.

Sustainability emerges as another key focus, with 5G supporting efforts to reduce energy consumption and physical infrastructure needs. However, challenges such as rising power demands for connected devices must be navigated carefully to ensure long-term viability. Manufacturers need to balance technological advancements with resource efficiency to align with environmental goals.

Cultural shifts toward data-driven operations also present hurdles, as organizations must foster mindsets that embrace real-time analytics over traditional methods. Preparing for these shifts involves investing in training and infrastructure that support 5G’s capabilities. By anticipating these trends and challenges, businesses can position themselves to leverage the full spectrum of benefits that 5G offers in the industrial landscape.

Final Thoughts: Embracing 5G for a Competitive Edge

Reflecting on the journey through 5G’s impact on manufacturing, it becomes clear that this technology has redefined the essence of industrial operations as the linchpin of Industry 4.0. Each transformation, from real-time data processing to remote operations via AR/VR, has demonstrated how connectivity can elevate efficiency and innovation to new heights. The steps explored have laid a robust foundation for understanding the practical applications of 5G in smart factories.

Looking back, the detailed insights into automation and supply chain visibility have provided a blueprint for operational excellence. As a next step, manufacturers are encouraged to initiate pilot projects that test 5G integration in specific processes, gathering data on performance improvements. Partnering with technology providers can also accelerate this adoption, offering expertise and tailored solutions to navigate implementation challenges.

Beyond immediate actions, exploring collaborations with industry consortia to stay updated on 5G advancements has proven beneficial. Investing in workforce training to handle data-driven tools ensures that technological gains are matched by human capability. These forward-looking strategies promise to sustain the momentum of transformation, securing a competitive edge in an ever-digitizing industrial arena.