The field of industrial automation has taken a significant leap forward with the introduction of CapSen Robotics’ newest iteration of their advanced bin-picking software, PiC 2.0. This update heralds a new era in robotic pick-and-place operations, touting enhanced efficiency and adaptive capabilities that promise to revolutionize production lines across various sectors.

Revolutionizing Machine Vision with PiC 2.0

Advanced Image Analysis for Quicker Identification

PiC 2.0 ensures a radical improvement in machine vision, featuring sophisticated image processing that can quickly and accurately identify parts within a bin. The advanced algorithms are designed to dramatically shorten cycle times, a critical factor in maintaining high production rates. This capacity for rapid part recognition is especially beneficial for industries where time is of the essence, enabling robots to handle a higher volume of part picking without compromising precision.

AI-powered Flexibility in High-Mix Operations

One of the traditional challenges faced in the realm of industrial automation is managing high-mix, low-volume operations where variability is the norm. PiC 2.0 addresses this issue head-on with its AI-enriched software. The enhanced algorithms allow the system to adapt to a wide array of products, enabling seamless transitions between different picking tasks without the need for extensive reprogramming. This remarkable adaptability ensures that the software remains a vital asset in environments where product variations could previously stagger production processes.

Interface and Integration Enhancements

Intuitive User Interface Improvements

The upgraded UI of PiC 2.0 is designed to be incredibly user-friendly, allowing operators to configure and manage the system with ease. Whether adjusting parameters for different part shapes and sizes or troubleshooting, the interface ensures that any required interventions are straightforward and do not contribute significantly to downtime, thereby upholding a streamlined production flow.

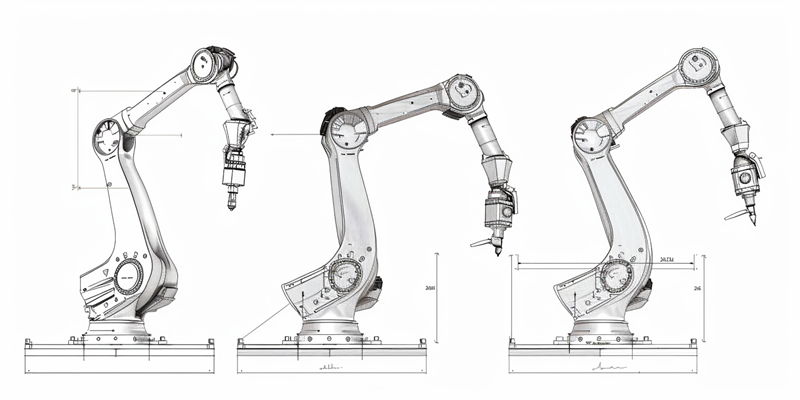

Adapting to Complex Robotics Hardware

Industrial automation has reached a new pinnacle with CapSen Robotics’ release of their improved bin-picking software, PiC 2.0. This upgrade marks a significant advancement in the domain of robotic pick-and-place tasks, providing unprecedented levels of efficiency and adaptability. PiC 2.0 has been engineered to set new benchmarks in robots’ ability to handle objects of varying shapes and sizes, ensuring smoother operational workflows. Positioned as a game-changer for manufacturing lines in diverse industries, from automotive to electronics, its intuitive algorithms can significantly speed up production processes by reducing the time robots spend locating and positioning items in bins. With its sophisticated features, PiC 2.0 is not just enhancing current production capabilities but is also paving the way for a future where robotic assistance is more nuanced and indispensable across the manufacturing landscape. This software promises not only to improve production efficiency but also to foster innovation in automated systems, driving industrial growth forward.