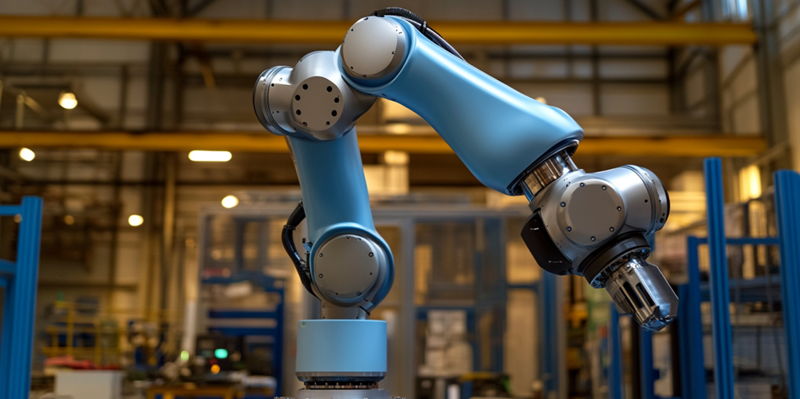

In a major leap forward in robotic technology, PickNik Robotics has just released MoveIt Pro 6, the latest iteration of its versatile, open development platform tailored for robotic applications spanning various industries. Unlike previous versions, this hardware-agnostic and AI-driven system now boasts a powerful simulation engine capable of creating highly accurate digital twins. This feature alone has the potential to transform how companies conceptualize and evaluate their physical assets and processes in virtual environments. The ability to simulate and perfect tasks digitally before physical implementation could save both time and resources, particularly in complex industrial settings. By offering a more streamlined and adaptable approach to robotic system development, MoveIt Pro 6 allows for unprecedented levels of flexibility and efficiency in automated and manual tasks alike, fundamentally changing the landscape for businesses relying on robotics.

AI Integration Enhances Flexibility and Speed

MoveIt Pro 6 breaks down traditional barriers in robotics by effectively leveraging Artificial Intelligence to dramatically enhance both flexibility and implementation speed. AI integration within the platform enables robotic systems to handle a wider variety of tasks, quickly adapt to changing environments, and improve operational efficiency through real-time data processing. One of the significant advancements includes the elimination of constant reprogramming, as adaptive algorithms allow robots to learn and refine their operations over time using machine learning. This results in a more autonomous system that can continually improve its performance without frequent human intervention. Furthermore, the inclusion of user-friendly technologies such as low-code or no-code platforms significantly shortens implementation timelines, making it easier for users to adopt without requiring advanced expertise. This democratization of robotic technology highlights the unique advantages of MoveIt Pro 6, allowing more organizations to leverage robotics without being bogged down by technical complexities.

In addition to adaptive algorithms, MoveIt Pro 6 offers a suite of tools and a Python-based API designed to facilitate the incorporation of custom machine learning models. This makes it easier for developers to tailor solutions to specific operational needs. A gamified GUI featuring drag-and-drop capabilities further simplifies rapid application development, enabling users to visually set goals and construct behavior trees without delving into complex code. For those interested in deploying robotic systems quickly, pre-trained foundation models are available. These versatile resources accelerate the readiness of applications, making it easier to integrate robotics into existing workflows swiftly. The combination of these features ensures that organizations can not only adopt robotic technology more easily but also customize and scale their deployments as needed.

Advanced Simulation for Comprehensive Development

One of the standout features of MoveIt Pro 6 is its advanced Digital Twin technology, which leverages realistic physics simulations to create a highly accurate virtual representation of physical tasks and systems. This level of simulation is particularly beneficial for users engaged in tasks such as bin-picking, welding, door operations, and assembly lines. By allowing users to test and refine processes in a virtual environment before implementing them in the real world, MoveIt Pro 6 can help identify and rectify potential issues early in the development phase. This not only accelerates the time-to-market but also reduces the likelihood of costly errors and downtime. The platform’s robust simulation capabilities are complemented by its interoperability with fleet management systems, offering a comprehensive operational overview that facilitates more efficient resource allocation and coordination among multiple robotic units.

The flexibility of MoveIt Pro extends to its support for a variety of components, including numerous robotic arms, end effectors, cameras, and auxiliary devices. This adaptable architecture allows users to customize their hardware setups according to specific operational requirements and budget constraints. By supporting standard components, MoveIt Pro 6 also enables users to reduce project costs while still achieving high levels of functionality and performance. The inclusion of motion primitives to form complex task sequences further enhances robotic planning and execution, enabling more sophisticated and precise operations. Powerful algorithms drive robot perception, motion control, planning, and teleoperation. In teleoperation scenarios, users can manually control robot joints and endpoints using Cartesian coordinates, providing granular control over robotic systems.

A Holistic Approach to Robotic Development

MoveIt Pro 6 stands out due to its advanced Digital Twin technology, which uses realistic physics simulations to create an accurate virtual model of physical tasks and systems. This high level of simulation is ideal for users working on bin-picking, welding, door operations, and assembly lines. By testing and refining processes in a virtual setting before real-world implementation, MoveIt Pro 6 identifies and resolves potential issues early in development. This not only speeds up time-to-market but also minimizes costly errors and downtime. The platform’s strong simulation features work well with fleet management systems, providing a comprehensive operational view that aids in efficient resource allocation and coordination among multiple robots.

MoveIt Pro’s flexibility is highlighted by its compatibility with various components, including different robotic arms, end effectors, cameras, and auxiliary devices. This adaptable setup lets users customize hardware configurations to meet specific operational needs and budget limits. By supporting standard components, MoveIt Pro 6 helps reduce project costs while maintaining high functionality and performance. Motion primitives are included to create complex task sequences, enhancing robotic planning and execution. Advanced algorithms improve robot perception, motion control, planning, and teleoperation. In teleoperation, users can manually control robot joints and endpoints via Cartesian coordinates for detailed management of robotic systems.