Effective maintenance management is crucial for ensuring the longevity and efficiency of company assets. For businesses using Microsoft Dynamics 365 Business Central, the Maintenance Manager app developed by Insight Works offers a powerful solution to enhance their maintenance operations. This article delves into how Maintenance Manager can streamline maintenance processes, maximize uptime, and optimize asset management through various innovative strategies and tools.

Automate and Optimize Maintenance Scheduling

Transitioning from manual to automated maintenance tracking is essential for proactive service. Manual tracking often results in missed service intervals, which subsequently lead to unexpected equipment breakdowns and costly downtime. By automating maintenance schedules based on metrics such as runtime, usage cycles, or calendar dates, businesses ensure that technicians receive timely reminders to service their assets. This proactive approach fundamentally enhances operational efficiency by reducing the likelihood of unexpected equipment failures and prolonging the lifespan of valuable machinery.

Another layer of optimization comes from the integration of MxAPS with Maintenance Manager. This combination allows businesses to correlate maintenance activities with their production plans, creating a symbiotic relationship between service schedules and manufacturing operations. When production schedules experience shifts or changes, MxAPS automatically updates the corresponding maintenance schedules. This dynamic synchronization ensures that maintenance activities are performed at the most efficient times, minimizing disruptions to production output and ultimately supporting a more robust operational framework. By eliminating conflicts between service and production schedules, businesses can achieve smoother workflow and greater resource utilization.

Enhance Work Order Management and Mobile Accessibility

Streamlined work order management is critical to executing efficient maintenance operations. Detailed work orders should contain precise instructions, the necessary allocation of resources, and clearly defined priority levels. This structured approach enables technicians to perform maintenance tasks more accurately and swiftly, as they have all the information needed at their fingertips. The result is enhanced task completion accuracy, quicker turnaround times, and overall improved maintenance outcomes. Additionally, clearly organized work orders reduce the likelihood of errors and miscommunications, resulting in higher quality service.

The need for real-time updates and mobility cannot be overstated when it comes to maintenance operations. Mobile access for field technicians and shop floor employees is crucial for efficient record-keeping and seamless communication. Using the Business Central mobile app, technicians can view and update assigned tasks, record the time spent on various activities, and update work statuses directly from their mobile devices. This capability eliminates the tedious and error-prone paperwork process, streamlines communication between maintenance teams and management, and ensures real-time data updates. By facilitating instant access to information and the ability to update records on-the-go, mobile accessibility enhances productivity and operational efficiency.

Leverage Historical Data and Ensure Spare Parts Availability

Utilizing historical data is vital for refining maintenance strategies and improving asset reliability. Through Maintenance Manager, businesses can store comprehensive historical data related to their equipment and maintenance activities. This extensive repository of information allows managers to identify recurring issues, track performance trends, and optimize maintenance intervals. By analyzing historical data, companies can make informed decisions about equipment upgrades, replacements, and other critical maintenance-related actions. This data-driven approach not only enhances asset reliability but also contributes to better financial planning and resource allocation.

Ensuring the availability of spare parts is another critical aspect of effective maintenance management. Maintenance delays often occur due to the unavailability of necessary spare parts, leading to prolonged downtime and increased operational costs. Business Central’s inventory tracking system can be leveraged to keep maintenance-related parts well-stocked and accessible. By flagging essential spare parts as “Maintenance Parts” within Maintenance Manager, businesses can prevent last-minute procurement delays and ensure timely repairs. This proactive inventory management approach minimizes potential disruptions and guarantees that maintenance procedures can be executed promptly, maintaining optimal productivity levels.

Customize Workflows and Attach Digital Documentation

Every business has unique maintenance procedures, and the ability to customize workflows within Maintenance Manager is crucial for meeting these specific needs. By tailoring fields, workflows, and reporting tools to their requirements, businesses can enhance the app’s efficiency and usability in various organizational contexts. Modifying data entry fields, automating approval processes, and creating custom maintenance categories enable a more seamless integration of the maintenance management system into everyday operations. This customization ensures that the app adapts to the specific workflows and processes of each organization, thereby enhancing overall functionality and user experience.

Attaching digital documentation to maintenance tasks can significantly improve efficiency and workplace safety. Maintenance Manager allows businesses to attach relevant documents such as equipment manuals, schematics, and safety instructions directly to maintenance tasks. This ensures that technicians have immediate access to all necessary information while performing maintenance, which can lead to more accurate and safer task execution. The availability of digital documents at the point of service reduces the risk of errors and enhances compliance with safety regulations. By providing instant access to critical documentation, businesses can create a more informed and safer work environment.

Implement Preventive Maintenance Strategies

Preventive maintenance is vital for maximizing the longevity and efficiency of a company’s assets. For businesses utilizing Microsoft Dynamics 365 Business Central, the Maintenance Manager app by Insight Works provides a robust solution to enhance their maintenance operations. Maintenance Manager offers a variety of innovative strategies and tools designed to streamline maintenance processes, maximize uptime, and optimize asset management.

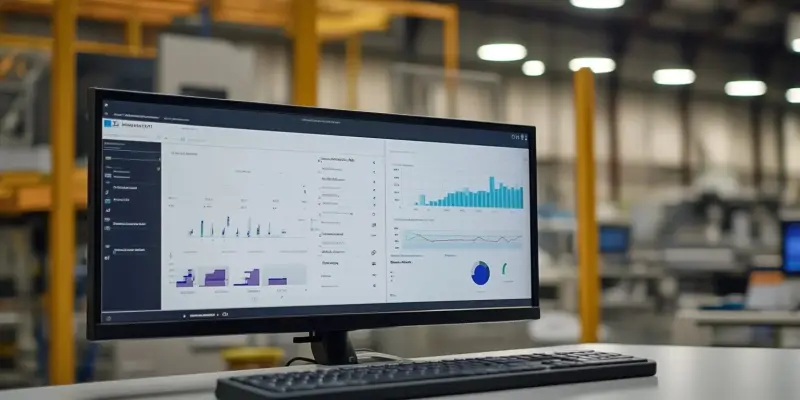

One of the key benefits of Maintenance Manager is its ability to automate and simplify scheduling, resulting in less downtime and better resource allocation. By integrating seamlessly with Microsoft Dynamics 365 Business Central, businesses can keep all their maintenance tasks and asset information centralized, ensuring easy access and better decision-making.

Additionally, Maintenance Manager enables proactive maintenance by providing real-time data, analytics, and insights. This allows businesses to anticipate issues before they become major problems, reducing long-term costs and preserving the reliability of critical assets. Through comprehensive tracking and reporting features, companies can maintain detailed records of maintenance activities, meeting compliance requirements and improving overall operational performance.