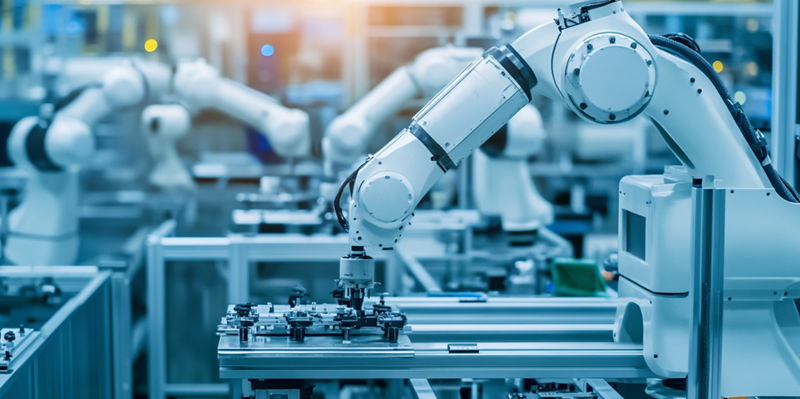

Modern manufacturing is undergoing a significant transformation, driven by the integration of robotics into production processes. As industries evolve to meet increasing demands for efficiency, quality, and competitiveness, robotics emerges as a pivotal force that fundamentally alters how factories operate. This article explores the multi-faceted impact of robotics on manufacturing, detailing their types, applications, and benefits while also addressing the challenges associated with their implementation. Additionally, it offers insights into the future trends poised to shape the industry.

Understanding Automation and Robotics

Automation in manufacturing entails the use of control systems and information technologies to reduce the need for human intervention. Robotics, a critical subset of automation, refers to using robots to perform tasks traditionally handled by humans. This shift is largely motivated by the quest for improved productivity, superior quality, and enhanced global competitiveness.

The Fundamentals of Automation

Automation, at its core, reduces human error, enhances consistency, and elevates overall efficiency. By leveraging control systems, manufacturers can streamline processes and minimize waste, translating into cost savings and increased productivity. Various automated technologies, from conveyor belts to sophisticated software systems, work in concert to optimize manufacturing operations by ensuring tasks are completed accurately and on time.

Modern automation extends beyond simple machinery and involves complex integrations with software that can analyze data in real time, predict maintenance needs, and even make adjustments to improve efficiency. These systems not only eliminate the variability introduced by human operators but also allow for continuous operation, which significantly boosts throughput. Moreover, automation provides a scalable solution that can grow alongside manufacturing needs, making it an indispensable element in today’s competitive landscape.

Defining Robotics

Robotics stands at the forefront of automation. In manufacturing, robots undertake tasks from simple assembly to complex quality inspections. Their operation spans various functions, ensuring tasks are executed with precision and speed. Robots are programmable and adaptable, providing manufacturers with the flexibility to quickly pivot and meet changing production demands.

Robots in manufacturing are typically equipped with advanced sensors and AI-powered systems that allow them to navigate complex environments and make split-second decisions. This adaptability is crucial in dynamic manufacturing settings where product lines and production requirements frequently change. Robots can be reprogrammed to perform multiple tasks, reducing downtime and increasing overall productivity. The precision that robots bring to the table ensures that each product is manufactured to exact specifications, thereby minimizing waste and rework, which are costly for any manufacturing facility.

Types of Robots in Manufacturing

Robots in manufacturing come in various forms, each tailored to specific applications. Their integration into production lines has revolutionized how tasks are performed, enhancing both efficiency and safety.

Industrial Robots

The most ubiquitous type, industrial robots, are designed for high-volume, repetitive tasks. These robots are workhorses in manufacturing environments, performing functions like welding, painting, assembly, and material handling with high precision and speed. Their reliability in executing monotonous tasks ensures consistent product quality and significantly reduces production lead times.

Industrial robots are often found in automotive manufacturing, where they handle a significant portion of the assembly process. They are capable of working around the clock, which drastically improves production rates and allows manufacturers to quickly ramp up production to meet market demands. The precision of industrial robots not only improves the quality of the final product but also reduces material waste, thereby making production more cost-effective. These robots are typically large, stationary units designed to perform specific tasks, but they can be tailored to meet various requirements within a manufacturing facility.

Collaborative Robots (Cobots)

Cobots are engineered to operate alongside human workers, bringing a new dimension of versatility to manufacturing floors. Unlike traditional robots that often require fencing and safety measures, cobots are designed with advanced safety features that allow them to work in close proximity to humans without posing risks. They supplement human efforts, handling tasks such as pick-and-place operations, complex assembly, and quality inspections.

Cobots are particularly valuable in environments where human dexterity and creativity are still required, but repetitive or dangerous tasks need to be automated. For instance, in electronics manufacturing, cobots can handle delicate components and assist with intricate assembly processes while humans oversee and manage quality control. The presence of cobots enhances worker productivity and reduces the strain of repetitive tasks, thereby improving job satisfaction and reducing the risk of injuries. Cobots are also easy to program and can be quickly redeployed for different tasks, offering unparalleled flexibility on the manufacturing floor.

Autonomous Mobile Robots (AMRs)

AMRs provide mobility and autonomy in manufacturing settings. They navigate production floors, transporting materials and products from one location to another independently. Equipped with sophisticated sensors and mapping technologies, AMRs enhance logistical efficiency and reduce the time required for intra-facility transport, often freeing human workers for more skilled tasks.

In large manufacturing facilities, the efficient movement of materials is crucial for maintaining smooth production flows. AMRs excel in this area by autonomously navigating complex layouts and ensuring that materials are delivered exactly where they are needed, just in time for production. These robots are designed to avoid obstacles and human workers, ensuring safety standards are met. By taking over the tedious task of material transport, AMRs allow human workers to focus on more value-added activities such as quality control, system monitoring, and complex problem-solving. This integration significantly reduces bottlenecks in the production process and enhances overall operational efficiency.

Benefits of Robotics in Manufacturing

The integration of robotics into manufacturing delivers numerous advantages, driving improvements across various aspects of production.

Improving Quality and Precision

Robots are synonymous with precision and consistency. By minimizing human error, they play a crucial role in maintaining uniformity and high quality in manufacturing outputs. This reliability not only enhances product quality but also fosters consumer trust and brand reputation. Robots are programmed to perform tasks to exact specifications, ensuring that every product coming off the production line meets the same high standards.

Quality is a critical factor in manufacturing, affecting everything from consumer satisfaction to regulatory compliance. Robots equipped with advanced sensors can perform real-time inspections and adjustments, identifying defects and making corrections instantaneously. This capability drastically reduces the likelihood of defective products reaching the market. The use of robots in quality assurance processes also speeds up inspections, allowing for faster production cycles without compromising on quality. In industries such as pharmaceuticals or aerospace, where precision is paramount, the use of robotics can make a significant difference in maintaining stringent quality standards.

Boosting Efficiency and Productivity

Robotic automation bolsters manufacturing efficiency. Robots can operate continuously without fatigue, leading to higher production rates and shorter lead times. This continuous operation significantly elevates overall productivity, allowing manufacturers to meet tight deadlines and high-demand cycles. The ability of robots to work around the clock without breaks or errors makes them invaluable assets in high-volume manufacturing environments.

Productivity gains from robotic automation not only improve throughput but also allow for more efficient resource utilization. Robots can handle multiple tasks simultaneously, reducing the need for multiple machines and freeing up space on the manufacturing floor. This efficiency extends to energy consumption as well; robots can be programmed to operate in the most energy-efficient manner possible, reducing the overall operational costs. Furthermore, the use of robotics allows for more precise scheduling and inventory management, as production times become more predictable. This predictive capability helps manufacturers optimize their supply chains and reduce lead times, leading to faster delivery to market.

Enhancing Workplace Safety

Robots can perform tasks in environments that are hazardous for humans, such as those with toxic chemicals or extreme temperatures. By taking on dangerous jobs, robots enhance worker safety, reducing the incidence of workplace injuries and the associated costs. The deployment of robots in hazardous environments not only protects human workers but also ensures that production continues without interruption in conditions that would otherwise pose significant risks.

Workplace safety is a significant concern, particularly in industries involving heavy machinery, chemicals, or high temperatures. Robots designed for these environments come equipped with protective measures and specialized capabilities to handle dangerous materials or conditions. For example, in metal foundries, robots can manage molten metal, reducing the risk of burns and other injuries. In chemical plants, robots can handle toxic substances, minimizing exposure and potential health risks for workers. By improving safety, robots also contribute to a more positive workplace culture, as employees feel more secure and valued, leading to higher morale and productivity.

Challenges of Implementing Robotics

Despite the myriad benefits, integrating robotics into manufacturing presents several challenges that companies must navigate.

High Initial Investment

The cost of acquiring and installing robotic systems is substantial. This high upfront expenditure can be a barrier for smaller manufacturers or those with limited budgets. However, the long-term savings and efficiency gains often justify the initial investment. Financial considerations must account for not only the purchase price but also the costs associated with system integration, operator training, and ongoing maintenance.

For many manufacturers, the decision to invest in robotics involves a careful analysis of return on investment (ROI). While the initial costs can be daunting, the long-term benefits in terms of increased productivity, reduced labor costs, and enhanced quality often outweigh the initial outlay. Financing options and incentives from government programs or industry partnerships can help mitigate the initial financial impact. Additionally, the modular nature of modern robotic systems allows for phased implementations, enabling manufacturers to start small and scale up as they realize savings and increased productivity.

Job Displacement Concerns

One of the most significant concerns surrounding robotics in manufacturing is the potential for job displacement. As robots take over repetitive and mundane tasks, there is a fear of reduced employment opportunities for workers, prompting discussions about economic and social impacts. The shift necessitates a rethinking of workforce roles and the creation of new opportunities for skill development and job transitions.

To address these concerns, companies and policymakers must focus on upskilling and reskilling workers. Training programs tailored to equip workers with the skills necessary to manage, program, and maintain robotic systems can help mitigate job losses. Collaborative robots, or cobots, present a unique opportunity to enhance human-robot collaboration rather than replacement. By working alongside robots, human workers can take on more complex and strategic roles, focusing on tasks that require creativity, problem-solving, and decision-making. The integration of robotics should be viewed as an evolution of the workforce, necessitating a proactive approach to workforce development.

Maintenance and Upgrades

Robotic systems require regular upkeep and upgrades to ensure optimum performance. This need for ongoing maintenance necessitates specialized skills and can occasionally disrupt production schedules. Manufacturers must establish dedicated teams or partnerships to manage these aspects, ensuring that their robotic systems continue to operate efficiently and effectively.

The long-term success of robotic integration depends heavily on effective maintenance strategies. Predictive maintenance, powered by AI and IoT technologies, can help anticipate and address issues before they lead to downtime. Regular training and certification programs for maintenance personnel are essential to keep them abreast of the latest technological advancements and best practices. Partnerships with original equipment manufacturers (OEMs) can also provide access to specialized expertise and support. While the maintenance of robotic systems poses challenges, effective strategies and planning can help minimize disruptions and maximize the benefits of automation.

Future Trends in Robotics for Manufacturing

The future of robotics in manufacturing is set to be shaped by continuous technological advancements, promising even greater efficiency and innovation.

Integration with Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are at the forefront of future trends in robotics. Incorporating these technologies allows robots to learn and adapt to new tasks over time, enhancing their effectiveness and reducing the need for constant programming. This advancement will enable more intelligent and autonomous manufacturing processes, capable of self-optimization and predictive maintenance.

AI and ML can significantly enhance the capabilities of robotic systems. Machine learning algorithms can analyze performance data to identify patterns and make improvements, ensuring that robots become more efficient over time. AI can enable robots to perform complex tasks that require decision-making and problem-solving, further extending their utility in manufacturing environments. The integration of AI and ML also facilitates real-time data analytics, allowing manufacturers to make informed decisions and optimize production processes dynamically. These advancements will continue to drive the evolution of smart factories, where interconnected systems work seamlessly to deliver unparalleled productivity and quality.

The Role of the Internet of Things (IoT)

The world of manufacturing is experiencing a notable shift with the integration of robotics into production lines. As companies strive to meet growing demands for higher efficiency, improved quality, and enhanced competitiveness, robotics is becoming a game-changer that drastically changes factory operations. This article delves into the various ways robotics is influencing manufacturing. It covers the different types of robots used, their applications, and the benefits they bring, such as increased precision, reduced human error, and lower production costs. However, it also highlights the challenges that come with adopting these technologies, including the significant initial investment and the need for skilled personnel to manage and maintain complex robotic systems.

Furthermore, the article looks ahead at future trends aspiring to revolutionize the industry even more. For example, advancements in artificial intelligence are expected to make robots smarter and more adaptable, allowing them to perform increasingly complex tasks. Additionally, the increased connectivity brought by the Internet of Things (IoT) will enable more integrated and streamlined manufacturing processes, driving further efficiencies. Keeping these trends in mind will be crucial for companies aiming to stay competitive in a rapidly evolving marketplace.