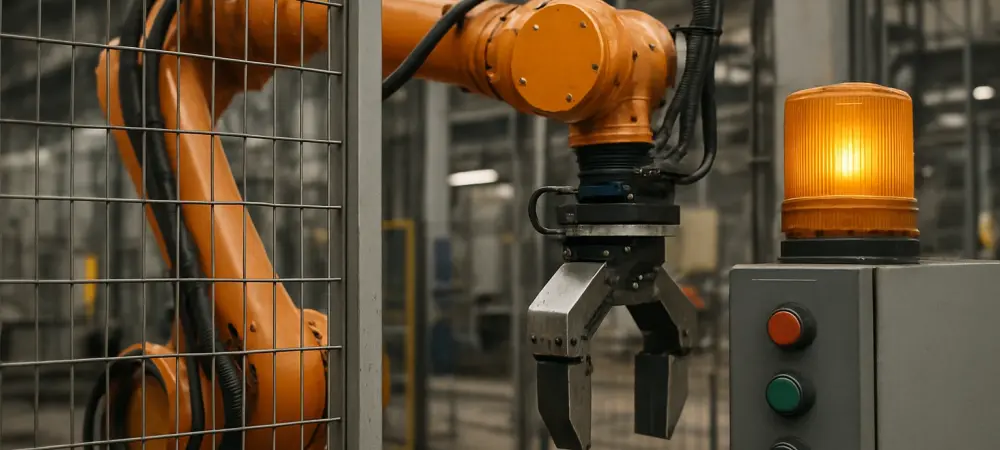

In the fast-evolving world of industrial automation, ensuring the safety of mobile robots like automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) remains a critical challenge. With industries increasingly relying on these systems for efficiency, a single safety lapse can lead to catastrophic consequences, halting operations and endangering personnel. Enter a solution from HMS Networks that promises to revolutionize safety standards for mobile robotics. This review dives deep into a cutting-edge technology designed to centralize safety-critical data and enhance control, exploring how it addresses the pressing demands of modern industrial environments.

Core Features and Safety Standards

Unmatched Safety Certifications

At the heart of this system lies its adherence to rigorous safety standards, evidenced by the prestigious TÜV certification. This accolade confirms compliance with Safety Integrity Level 3 (SIL 3) and Performance Level e/Category 4 (PLe/Cat. 4), benchmarks that signify exceptional reliability and fault tolerance. Such certifications ensure an extremely low probability of failure, a vital attribute for high-stakes industrial applications.

These standards also offer practical benefits for manufacturers and system integrators. By meeting these stringent requirements, the system simplifies the development and approval processes, reducing time-to-market for new robotic solutions. This reliability translates into fewer operational disruptions, bolstering confidence in deploying mobile robots across diverse settings.

Innovative Safety Stop Functionality

Another standout feature is the advanced safety stop mechanism, engineered to prevent abrupt halts that could destabilize operations. Upon detecting a safety trigger, the system initiates a controlled speed reduction, maintaining stability before activating Safe Torque Off (STO) to cut power to drive motors. This methodical approach ensures secure stops without mechanical shocks.

This functionality proves invaluable in dynamic environments where sudden stops can pose risks to both equipment and personnel. By prioritizing stability during emergency scenarios, the system enhances overall safety while preserving the integrity of ongoing processes, setting a new benchmark for mobile robot control.

Durability and Integration Capabilities

Built for Harsh Industrial Conditions

Industrial settings often expose equipment to challenging conditions, and this system rises to the occasion with a robust design. Encased in an IP54-rated enclosure, it offers protection against water sprays and dust ingress, ensuring consistent performance in tough environments. The inclusion of durable M12 Ethernet connectors further reinforces its resilience. This rugged construction makes the system a reliable choice for factories, warehouses, and outdoor applications where exposure to elements is unavoidable. Its ability to withstand such conditions minimizes maintenance needs, allowing industries to focus on productivity rather than equipment downtime.

Seamless Plug-and-Play Design

Ease of integration is another hallmark of this technology, thanks to its plug-and-play setup supported by a Sistema library for straightforward safety function approval. Its compact form factor and adaptable address settings cater to a wide range of installations, from new builds to retrofits of older systems. Additionally, compatibility with a broad temperature range enhances its versatility. Alignment with contemporary regulations, such as ISO 3691-4 and EU 2023/1230, ensures that deployments meet current safety mandates. This adaptability not only simplifies implementation but also future-proofs investments, making the system a strategic asset for evolving industrial needs.

Operational Advantages in Real-World Scenarios

Enhancing Safety in Mobile Robotics

In practical applications, this system shines by bolstering safety for AGVs and AMRs across various industries. By centralizing data from sensors and input devices, it enables rapid transmission to control systems or programmable logic controllers (PLCs), facilitating swift hazard prevention. This capability is critical in high-traffic environments like manufacturing plants.

Beyond risk mitigation, the system supports operational continuity by minimizing false stops and unnecessary interruptions. Industries can thus maintain workflow efficiency while adhering to stringent safety protocols, striking a balance between productivity and precaution.

Energy Efficiency and Power Management

An often-overlooked benefit is the system’s contribution to energy optimization through embedded non-safe inputs and outputs. These features allow precise remote power management, enabling controlled restarts and efficient handling of power-intensive components. As a result, battery life for mobile robots is extended significantly.

This energy-conscious design not only reduces operational costs but also aligns with sustainability goals, a growing priority in industrial sectors. Companies adopting this technology can achieve measurable savings while maintaining high performance standards, a dual advantage in competitive markets.

Potential Challenges and Limitations

Integration Complexities in Diverse Systems

Despite its many strengths, integrating this system into varied industrial setups can present hurdles. Compatibility with legacy equipment or non-standard configurations may require additional customization, potentially increasing deployment timelines. Such technical challenges could deter smaller enterprises with limited resources.

Moreover, navigating regulatory compliance across different regions adds another layer of complexity. While the system meets key international standards, localized requirements might necessitate further adjustments, posing a barrier to seamless adoption in global markets.

Ongoing Development Efforts

Recognizing these challenges, efforts are underway to enhance compatibility and simplify integration processes. From now through the next couple of years, expect updates aimed at broadening the system’s applicability across diverse platforms. These initiatives focus on reducing technical barriers and ensuring compliance with an even wider array of regional standards.

Such proactive development underscores a commitment to accessibility, aiming to make advanced safety solutions available to a broader spectrum of industries. This adaptability will likely drive greater adoption, addressing current limitations effectively.

Future Prospects for Mobile Robot Safety

Emerging Trends and Innovations

Looking ahead, the trajectory of mobile robot safety systems points toward greater automation and smarter technologies. Integration with artificial intelligence and real-time analytics could further enhance hazard detection and response times. This system is well-positioned to evolve alongside such advancements, potentially incorporating predictive safety features.

The push for scalability in industrial automation also suggests a growing demand for modular safety solutions. As industries expand their robotic fleets, systems that can adapt to larger, more complex operations will become indispensable, paving the way for broader implementation of this technology.

Long-Term Impact on Industrial Automation

Over the coming years, the influence of robust safety systems on industrial efficiency and risk management will likely intensify. By setting a high standard for reliability and integration, this technology could inspire a new wave of safety-focused innovations. Its role in shaping safer, more efficient workplaces cannot be overstated. As regulatory frameworks continue to evolve, alignment with such systems will become a competitive differentiator. Industries that invest in cutting-edge safety solutions now will be better equipped to navigate future challenges, ensuring both compliance and operational excellence.

Final Verdict and Next Steps

Reflecting on the comprehensive evaluation, it is clear that the system from HMS Networks stands out as a pioneering solution in mobile robotics safety. Its blend of top-tier certifications, durable design, and operational benefits makes a strong case for its adoption across industrial sectors. The technology proves itself as a reliable tool for mitigating risks and enhancing efficiency in demanding environments.

For industries looking to implement or upgrade safety systems, the next step involves assessing specific operational needs against the system’s capabilities. Engaging with integrators to address potential compatibility issues is crucial, as is staying informed about upcoming enhancements. By taking these actions, companies can leverage this technology to not only meet current safety demands but also prepare for the evolving landscape of industrial automation.