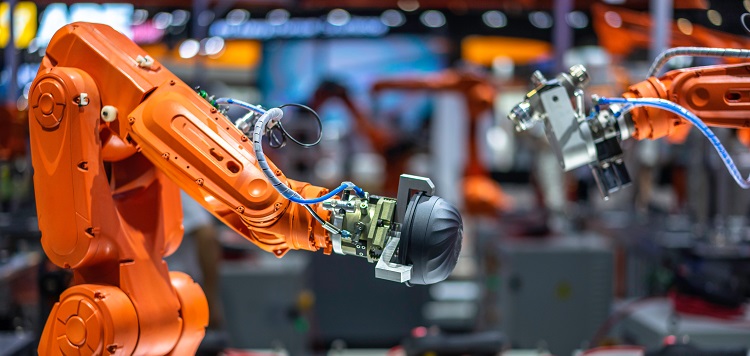

As the manufacturing industry becomes increasingly complex, businesses are searching for ways to streamline their processes and improve efficiency. Hexagon’s Manufacturing Intelligence division has recently launched a new solution that aims to meet these demands: PRESTO – an automated robotic inspection cell.

This cutting-edge technology promises to offer numerous benefits, including reduced quality inspection times, increased efficiency, and streamlined workflows. However, what exactly is PRESTO, and how can it help manufacturers adapt to the shifting industry landscape?

What is PRESTO?

PRESTO is a state-of-the-art automated robotic inspection cell developed by Hexagon. This technology offers a range of features designed to streamline quality control processes and improve efficiency in the manufacturing industry.

According to Hexagon, the goal of PRESTO is to enable its customers to reduce quality inspection times, increase efficiency, and streamline workflows. The company argues that this technology is an essential tool for companies looking to stay ahead of the curve in the rapidly-evolving manufacturing landscape.

Adapting to Shifts in the Industry: The Importance of PRESTO

One of the most pressing challenges facing manufacturers today is the shift towards electric vehicles (EVs) over internal combustion engines (ICEs). Businesses need to adapt to this changing landscape, but they cannot afford to retool their entire production line for EV manufacturing.

PRESTO offers a solution to this problem by enabling manufacturers to connect inspections to the rest of their ecosystem. As a result, businesses can automate processes, improve quality control, and ultimately reduce time to market.

Connecting Inspection to the Rest of Your Ecosystem

One of the critical features of PRESTO is its ability to connect inspections to the rest of a manufacturer’s ecosystem. This technology is designed to make it easier for businesses to automate processes, improve quality control, and reduce time to market.

For instance, with PRESTO, manufacturers can easily integrate inspection data into their existing systems, such as Enterprise Resource Planning (ERP) platforms. This means that the data generated from inspections can be used to improve overall efficiency and streamline workflows across the entire organization.

Easy to use and minimal setup required

Implementing new technology can be intimidating, particularly when it involves robotics. However, Hexagon designed PRESTO to be as easy to use as a smartphone. This solution requires minimal setup, and the automation process is effortless.

This design means that businesses can automate their inspection process without requiring a robotics expert to run it. This streamlines the adoption of the technology and makes it accessible to a broader range of companies, including those that might not have significant resources to invest in technology.

Addressing the challenges of automating the inspection process

Automating the inspection process is something that most manufacturers are keen to do. However, historically, it has been a challenging task. These systems are often complex, expensive, and require advanced robotics expertise to operate. PRESTO aims to solve these challenges by making automated inspection accessible to all suppliers, not just large OEMs.

Empowering Manufacturers with Critical Quality Data

At Hexagon, the mission is to empower manufacturers with fast access to critical quality data. PRESTO is a part of that effort, aiming to enable automated inspection processes and improve quality control across the industry.

With PRESTO, manufacturers can automate processes, improve quality control, and ultimately reduce time to market. This technology offers a powerful tool for businesses looking to stay ahead of the curve in the shifting manufacturing landscape.

As the manufacturing industry becomes increasingly complex, it is essential for businesses to find ways to streamline their processes and improve efficiency. With PRESTO, Hexagon’s new automated robotic inspection cell, manufacturers can do just that.

This technology offers numerous benefits, including reduced quality inspection times, increased efficiency, and streamlined workflows. The shift towards Electric Vehicles (EVs) over Internal Combustion Engines (ICEs) presents a significant challenge for manufacturers. However, PRESTO offers a solution by enabling businesses to connect inspections to the rest of their ecosystem.

Ultimately, PRESTO is part of Hexagon’s broader mission to empower manufacturers with fast access to critical quality data. This solution offers the future of automated inspection and has the potential to make serious waves in the manufacturing industry.