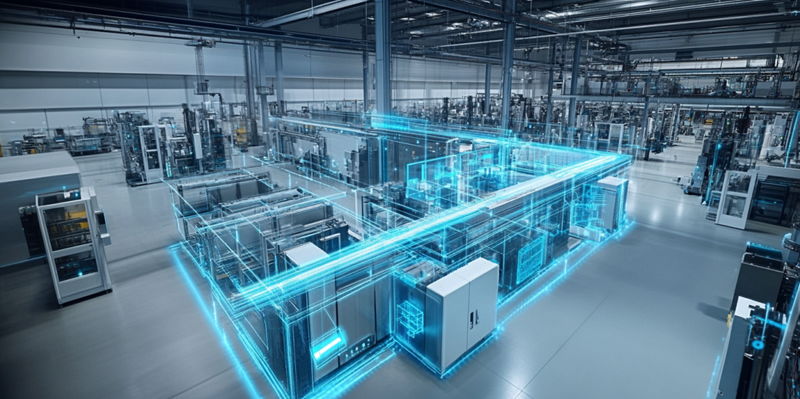

Imagine a world where factories run with unparalleled efficiency, where machines can predict their own failures, and where products are produced with zero defects. This is the vision of Industry 4.0, a revolution that blends physical production with continuous digital technology upgrades. At the heart of this transformation is Microsoft Dynamics 365, a comprehensive suite of applications designed to integrate and simplify the complex operations of modern manufacturing. By leveraging the power of IoT, AI, robotics, and cloud computing, Dynamics 365 turns traditional factories into smart factories that are agile, efficient, and ready to meet the demands of a competitive global market.

Transforming Manufacturing with Dynamics 365

Data Integration and Visibility

One of the core strengths of Microsoft Dynamics 365 in revolutionizing manufacturing lies in its capability to integrate data from multiple sources, providing comprehensive visibility into all aspects of operations. This integration is not just limited to internal systems; it extends to suppliers, partners, and customers as well, creating a cohesive ecosystem where data flows seamlessly and is accessible in real-time. This allows manufacturers to monitor every stage of the production process, from raw material procurement to the final delivery of finished goods. With this level of visibility, potential issues can be identified and addressed before they escalate, ensuring smoother operations and higher quality outcomes.

In addition, Dynamics 365 harnesses advanced analytics to offer predictive insights, transforming raw data into actionable intelligence. By applying AI algorithms, manufacturers can predict equipment failures before they occur, schedule maintenance proactively, and avoid costly downtime. Furthermore, this predictive ability extends to other areas such as supply chain management, where it can forecast demand patterns and optimize inventory levels, reducing waste and improving service levels. The real-time insights provided by Dynamics 365 empower decision-makers at all levels to make informed choices swiftly, enhancing overall operational efficiency and driving continuous improvement.

Predictive Maintenance

One of the most significant advantages of adopting Microsoft Dynamics 365 in manufacturing is its ability to support predictive maintenance strategies. In traditional manufacturing setups, maintenance is often reactive, with repairs only happening after a machine breaks down. This approach can lead to unexpected downtime, lost productivity, and increased costs due to emergency repairs. Dynamics 365 changes this paradigm by leveraging IoT sensors and AI analytics to continuously monitor the health of machinery and predict when maintenance is needed. This proactive approach ensures that maintenance is performed just in time, avoiding breakdowns and extending the life of equipment.

The implementation of predictive maintenance through Dynamics 365 also leads to substantial cost savings. By preventing unexpected failures, manufacturers can avoid the expensive rush-order parts and emergency labor costs associated with repairs. Additionally, optimized maintenance schedules mean that machines are serviced only when necessary, reducing the frequency of maintenance activities and the associated downtime. This results in a more stable production process, where equipment is kept in peak condition without disrupting operations, leading to higher productivity and lower overall maintenance costs.

Enhancing Collaboration and Efficiency

Seamless Integration Across Departments

Microsoft Dynamics 365 is not just about integrating data; it also excels at fostering collaboration across departments. By unifying CRM and ERP capabilities, Dynamics 365 breaks down the silos that often exist within organizations, facilitating seamless communication and data sharing between different teams. For instance, the sales team can instantly access production schedules, inventory levels, and shipment statuses, enabling them to provide accurate updates to customers. Similarly, the production team can review customer orders and adjust production plans accordingly. This level of integration ensures that everyone is working with the same information, leading to better alignment and coordination across the organization.

Moreover, Dynamics 365 supports enhanced collaboration with external partners and suppliers, further amplifying its impact. By sharing relevant data such as demand forecasts, inventory levels, and production schedules with suppliers, manufacturers can synchronize their operations, reducing lead times and minimizing the risk of stockouts or overproduction. This collaborative approach extends to customers as well, where real-time insights into order statuses, delivery timelines, and product quality can enhance customer satisfaction and build stronger relationships. The ability to collaboratively plan, forecast, and execute operations in real-time is a key differentiator, enabling manufacturers to respond swiftly to market changes and customer demands.

Overcoming Implementation Challenges

While the benefits of transitioning to smart factories using Dynamics 365 are clear, the journey is not without its challenges. One of the primary hurdles is the integration of legacy systems with the new Dynamics 365 platform. Many manufacturers operate with outdated systems that were not designed for the level of connectivity and data integration that modern technologies demand. Successfully integrating these legacy systems requires careful planning, expertise, and often, a phased approach to minimize disruptions. However, the long-term benefits of a unified, data-rich environment far outweigh the initial challenges, making it a worthwhile investment.

Another significant challenge is ensuring data security in an increasingly interconnected landscape. With the proliferation of IoT devices and the widespread use of cloud computing, manufacturers must implement robust cybersecurity measures to protect sensitive data from breaches and cyber-attacks. Comprehensive security protocols, regular audits, and continuous monitoring are essential to safeguard data integrity and confidentiality. Additionally, managing the cultural shift within organizations as they adopt new technologies is crucial. Employees may be resistant to change, and it is vital to provide adequate training and support to help them transition smoothly and embrace the new way of working.

Preparing for the Future of Manufacturing

Embracing Industry 4.0 Innovations

As manufacturers aim to stay ahead in a rapidly evolving industry, embracing the innovations of Industry 4.0 through Microsoft Dynamics 365 becomes increasingly vital. Dynamics 365 is designed to be scalable and adaptable, offering manufacturers the flexibility to expand their operations and integrate new technologies as they emerge. The combination of IoT, AI, and cloud solutions provided by Dynamics 365 not only optimizes current manufacturing processes but also prepares organizations for future advancements. This readiness ensures that manufacturers can continuously improve their operations, innovate faster, and meet the ever-changing demands of the market.

Furthermore, the agility provided by Dynamics 365 allows manufacturers to pivot quickly in response to new opportunities and challenges. Whether it is introducing new products, entering new markets, or adapting to changes in consumer behavior, the advanced capabilities of Dynamics 365 enable manufacturers to make data-driven decisions with confidence. This proactive approach helps companies remain competitive, seize growth opportunities, and sustain long-term success. The integration of cutting-edge technologies and the ability to leverage real-time data insights are essential for manufacturers looking to thrive in the era of Industry 4.0.

Ensuring Competitive Advantage

Imagine a world where factories operate with unmatched efficiency, where machines can foresee their own malfunctions, and where products are consistently produced without any defects. This is the vision of Industry 4.0, a revolution that merges physical production processes with ongoing advancements in digital technology. At the core of this transformation lies Microsoft Dynamics 365, an extensive suite of applications crafted to streamline and simplify the intricate operations of contemporary manufacturing. By harnessing the capabilities of IoT, AI, robotics, and cloud computing, Dynamics 365 transforms conventional factories into smart factories. These smart factories are not only agile and efficient but also poised to meet the challenges and demands of a fiercely competitive global marketplace. The integration of these technologies ensures that manufacturing processes are not just optimized for efficiency but also aligned with the future of innovation, making manufacturing smarter, more predictive, and responsive to ever-changing market needs.