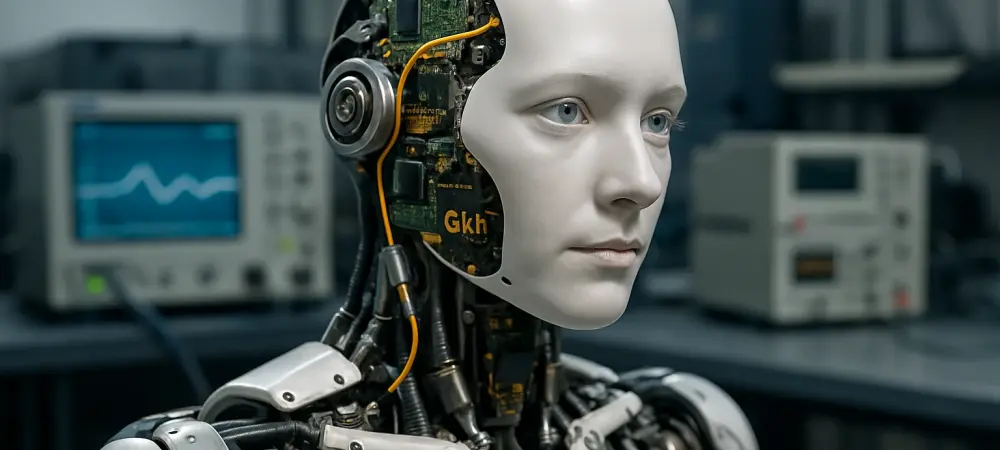

Imagine a world where robots move with such precision that they can perform delicate surgeries or assemble micro-components without a hint of jitter, a reality now being shaped by advancements in motor drive technology. Gallium Nitride (GaN) motor drives, particularly through pioneering platforms like QPT’s MicroDyno, are redefining motion control in collaborative robots (cobots) and other high-stakes applications. This review delves into the transformative potential of GaN-based systems, exploring how they tackle longstanding inefficiencies and set new benchmarks for performance across industries.

Understanding the Power of GaN in Motor Drives

GaN technology stands out in the realm of motor drives due to its exceptional switching speed and efficiency, far surpassing traditional silicon-based systems. Unlike conventional drives that struggle with sluggish response times and energy losses, GaN enables rapid transitions, minimizing heat dissipation and boosting overall system performance. This leap forward addresses critical challenges in robotics and industrial automation, where precision and energy conservation are paramount.

The emergence of GaN motor drives comes at a pivotal moment when industries are grappling with the limitations of low-frequency Pulse Width Modulation (PWM) systems. These older technologies often result in torque ripple and electromagnetic interference (EMI), causing uneven motion and increased wear on components. GaN offers a compelling solution by facilitating smoother outputs and cleaner signals, paving the way for more reliable and efficient machinery.

In the broader technological landscape, GaN motor drives are becoming integral to AI-ready systems that demand high precision and adaptability. Their ability to handle complex tasks with minimal latency aligns perfectly with the needs of modern robotics, where seamless integration with artificial intelligence is increasingly essential. This positions GaN as a cornerstone for future innovations across diverse sectors.

Diving into QPT’s MicroDyno Platform

Unpacking Ultra-High Frequency Operation at 1 MHz

QPT’s MicroDyno platform redefines motor drive capabilities with its groundbreaking 1 MHz switching frequency, a stark contrast to the lower frequencies of traditional systems. This ultra-high speed generates a true sine wave output, significantly reducing torque ripple and EMI. The result is an unprecedented level of motion smoothness, critical for applications where even minor vibrations can disrupt outcomes.

Such performance directly impacts robotics by alleviating mechanical stress on components like bearings and gears. The cleaner signal output not only extends the lifespan of these parts but also enhances overall system reliability. For cobots tasked with intricate operations, this translates into consistent and fluid movements that elevate operational standards.

Beyond individual performance, the high-frequency operation of MicroDyno allows for smaller, integrated filters, shrinking the footprint of motor drive systems. This compactness is a game-changer in space-constrained environments, enabling designs that are both powerful and efficient without sacrificing valuable real estate in robotic assemblies.

Exploring qSense Technology for Dynamic Precision

Another standout feature of the MicroDyno platform is its integrated qSense technology, which dynamically corrects torque ripple and cogging in real time. Unlike traditional setups that rely on external sensors for adjustments, qSense embeds this capability within the drive, slashing both complexity and cost. This innovation ensures precision without the burden of additional hardware.

The implications for cobot applications are profound, particularly in scenarios requiring meticulous control, such as medical procedures or fine-pitch manufacturing. By eliminating the need for external feedback mechanisms, qSense simplifies system architecture while maintaining high accuracy, making it easier to deploy robots in sensitive environments.

Additionally, this technology bolsters reliability by reducing points of failure associated with external components. The streamlined design not only cuts maintenance demands but also enhances the robustness of systems operating in challenging conditions, ensuring consistent performance over extended periods.

Tracking Recent Advances in GaN Motor Drive Solutions

The field of GaN motor drives is witnessing rapid evolution, with QPT leading the charge through modular innovations like the qIPM (Intelligent Power Module) and MicroVFD. These solutions integrate high-speed gate drivers and diagnostic tools into compact packages, catering to applications up to 75 kW. Such developments signal a shift toward versatile, high-performance systems tailored for diverse industrial needs.

A notable trend is the industry’s pivot away from outdated low-frequency PWM systems toward sine wave drives that prioritize efficiency. This transition addresses the growing demand for energy conservation, as sine wave outputs minimize losses that plague traditional setups. The push for greener technologies is thus finding a strong ally in GaN-based advancements.

These innovations also align with the integration of AI in robotics, where precise timing and responsive control are non-negotiable. As systems become smarter, the ability of GaN drives to deliver picosecond-level accuracy ensures they remain at the forefront of technological progress, supporting the complex requirements of next-generation automation.

Real-World Impact Across Industries

In collaborative robotics, QPT’s MicroDyno platform shines by enabling unparalleled precision for tasks like surgical interventions and micro-assembly in manufacturing. The smooth motion and reduced noise levels it provides are critical for environments where accuracy is everything, ensuring robots can handle delicate operations without error.

Unique implementations, such as embedding drives directly into robotic joints, further highlight the technology’s adaptability. This approach cuts down on cabling, simplifies designs, and improves electromagnetic compatibility (EMC), making it easier to meet stringent regulatory standards. The result is a more integrated and efficient robotic framework.

Looking beyond robotics, the versatility of GaN motor drives opens doors in industrial automation, HVAC systems, and electric vehicle (EV) traction drives. With electric motors consuming nearly half of global electricity, the potential to enhance energy efficiency in these sectors through scalable GaN solutions could yield significant economic and environmental benefits, reshaping how power is utilized.

Navigating Challenges in Adoption

Despite its promise, integrating high-frequency GaN systems into existing infrastructures poses technical hurdles. The complexity of adapting legacy equipment to handle ultra-fast switching speeds requires careful engineering and often substantial redesigns, which can deter rapid deployment across industries.

Market barriers also loom large, with cost considerations and the absence of universal standards slowing widespread acceptance. High initial investments for GaN technology may limit access for smaller players, while the lack of standardized protocols complicates integration efforts, creating friction in adoption timelines.

Ongoing efforts by QPT and other innovators aim to address these obstacles by refining scalability and reducing costs. Developing solutions that span various power levels and applications is a priority, as is advocating for industry consensus on standards to streamline implementation and foster broader market confidence.

Envisioning the Road Ahead

The trajectory of GaN motor drive technology points to exciting possibilities, particularly in scaling to higher voltages like 400 V and 800 V. Such advancements would expand the reach of platforms like MicroDyno, enabling them to power larger systems in industrial and automotive contexts, where robust performance is critical.

Anticipated breakthroughs in energy efficiency hold profound implications for global electricity consumption. By curbing losses in electric motors through advanced sine wave drives, the technology could contribute significantly to sustainability goals, reducing the carbon footprint of countless operations worldwide.

Long-term, the impact of GaN on robotics, EVs, and industrial automation promises to be transformative. As systems grow more interconnected and intelligent, the role of high-frequency drives in enabling seamless, efficient motion control will likely become a linchpin for innovation, driving progress across multiple domains.

Reflecting on a Technological Milestone

Looking back, the exploration of QPT’s MicroDyno platform revealed a remarkable stride in motor drive technology, adeptly addressing challenges of precision and efficiency with GaN-based innovation. Its impact on collaborative robots proved substantial, setting a new standard for smooth and reliable motion in critical applications. To move forward, stakeholders should focus on accelerating the development of cost-effective solutions and establishing industry-wide standards to ease integration. Collaborative efforts between innovators and regulators could unlock the full potential of this technology, ensuring its benefits reach a wider array of sectors while contributing to a more sustainable future.