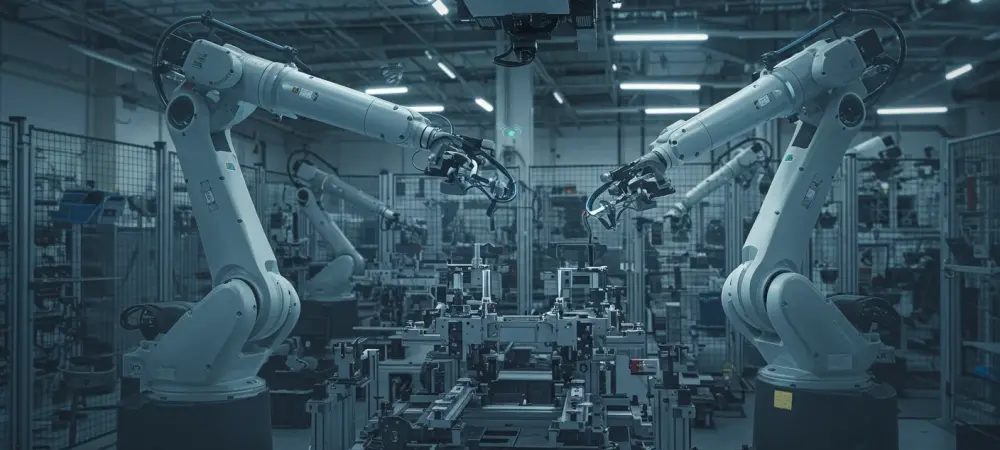

In the rapidly advancing world of technology, collaborative robotics is revolutionizing how industries operate by enhancing productivity and enabling seamless human-machine interaction. Recent developments vividly illustrate the growing focus on safety, precision, and versatility as key factors in reshaping industrial processes. As companies worldwide strive to adopt innovative technologies, the emergence of collaboration-driven robotics marks a significant step forward both for industry standards and business practices.

Key Features and Technological Excellence

Advanced Safety Mechanisms

Advanced safety features have become a cornerstone of collaborative robotics, ensuring safe and efficient coexistence between humans and machines. Essential mechanisms such as force sensors, vision systems, and compliance measures mitigate risks during interactions. These solutions enhance productivity by allowing robots to work side by side with employees, eliminating the need for isolated workspaces. Moreover, such safety advancements not only protect operators but also allow for optimized workflow and increased operational efficiency.

Enhanced Precision and Dexterity

Precision and dexterity are pivotal in distinguishing new-age robotics from traditional systems. State-of-the-art components like high-resolution sensors and refined motion algorithms enable collaborative robots to perform intricate tasks with remarkable accuracy. The outcome is evident across a variety of applications where precision is paramount, such as electronics assembly and laboratory automation. Significant improvements are observed in efficiency and performance metrics, showcasing a monumental leap toward advanced industrial robotics.

Emerging Trends and Industry Innovations

Recent innovations within collaborative robotics showcase a trajectory toward greater speed, flexibility, and intelligence. Developments like Dobot’s CR 30H series exemplify the shift toward robust solutions that prioritize operational versatility without compromising safety, with innovative models that cater specifically to high-payload tasks. Industry preferences increasingly reflect a demand for transformative applications where robots extend beyond mere mechanisms of automation, evolving into intelligent collaborators.

Consumer expectations continue to drive innovation, with emphasis placed on intelligent systems that effortlessly integrate with current technologies. Such industry trends are paving the way for collaborative robots offering a balance of adaptability and performance, catering to the evolving needs of diverse sectors.

Practical Applications and Pioneering Use Cases

Collaborative robots significantly impact a range of industries, from manufacturing and healthcare to agriculture and beyond. The latest generation of robotics excels in scenarios requiring precision and adaptability. Examples include Dobot’s Atom, moving toward real-world tasks like fruit picking—demonstrating the technology’s ingenuity. By showcasing multiple applications, robots are proving their worth in diverse settings, further validating their role in revolutionizing typical and atypical industrial environments. The versatility of collaborative robots, adaptable to unique and challenging scenarios, underscores their potential as future industry staples. As practical applications continue to expand, businesses gain the ability to enhance efficiency while maintaining rigorous safety standards.

Challenges and Limitations Faced by the Industry

Despite remarkable advancements, collaborative robotics grapples with challenges that hinder broader implementation. Technical complexities in seamless human-robot cooperation, coupled with regulatory constraints, pose significant barriers. Market adoption, although progressing, needs addressing persistent issues such as standardization and cost-effectiveness. Continued efforts remain focused on improving interoperability across platforms, increasing cost efficiency, and ensuring compliance with safety regulations. Resolving these challenges is essential for collaborative robotics to achieve the widespread industrial penetration necessary for its potential to be fully realized.

Prospects for Collaborative Robotics in Future Landscapes

The trajectory of collaborative robotics suggests a future brimming with potential breakthroughs. As industry dynamics shift towards intelligent automation, incorporating AI and machine learning into robotic platforms promises to unlock unprecedented capabilities. Anticipated advancements may include further improvements in AI algorithms and dexterous design, leading to robots that seamlessly integrate into existing infrastructure. The implications are vast, enhancing productivity while minimizing effort and opening new avenues across industries. As collaborative robotics technology evolves, perhaps it will redefine what is feasible across societal and industrial landscapes.

Concluding Thoughts

Reflecting on their progress thus far, collaborative robotics elevated operational standards and transformed industry practices by fostering synergy between humans and machines. Their development marked a pivotal point in the technological landscape by blending safety, precision, and adaptability. As related fields continue evolving, the opportunity to shape future innovation awaits, promising new heights in technological achievements and empowering industries to accomplish unprecedented feats.