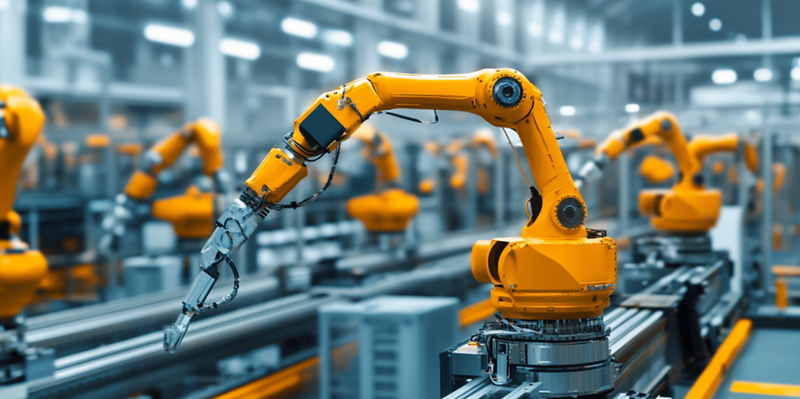

KUKA, a renowned name in robotics and automation, has recently expanded its KR SCARA robot series by introducing the KR 20 and KR 60 models. These robots are designed to handle higher payloads while ensuring precision, versatility, and ease of integration into modern production environments. As industries push towards higher efficiency and cost-effectiveness, KUKA’s new offerings may well be a game-changer.

Enhanced Payload Capacities for Diverse Applications

With the KR 20 and KR 60 models, KUKA has made significant strides in expanding the payload-handling capacities of its SCARA robots without compromising on efficiency or precision. The KR 20 model distinguishes itself with a compact profile and a notable payload capacity of up to 20 kg. Available in three reach options—800 mm, 1000 mm, and 1200 mm—the KR 20 is engineered for stable and accurate operations, thanks to its precise and rigid A1 axis. The integration of a cable connector plate on top of the A2 axis further simplifies its installation into both new and existing automation systems, making it a versatile choice for diverse industrial applications.

KR 20: Combining Compact Design with High Payload

A distinctive feature of the KR 20’s design is its compact yet robust build, allowing it to support substantial payloads while maintaining a small footprint. This makes it an ideal solution for smaller production environments where space might be limited but the demand for high payload capacity remains. The model’s versatility in reach options—800 mm, 1000 mm, and 1200 mm—enables it to adapt to different operational needs effectively. Engineered with a precisely calibrated and rigid A1 axis, the KR 20 ensures extremely stable and accurate operations, which are crucial for high-precision tasks in various industries. Additionally, the cable connector plate on the A2 axis is a thoughtful design inclusion that facilitates simpler, more streamlined integration into existing automation systems, significantly reducing setup time and complexity.

KR 60: Handling Heavier Loads with Ease

For industries requiring even greater payload capabilities, the KR 60 model offers a robust solution. Capable of managing loads up to 60 kg, it maintains a 1:2 payload-to-weight ratio without sacrificing either rigidity or precision. This model is particularly well-suited for heavy-duty tasks that demand high standards of accuracy and stability. Its four-axis design eliminates the need for steel structure mounting or planar referencing, making the installation process remarkably straightforward. This advanced design not only simplifies the setup but also ensures that the robot maintains its precision and stability during operation, which is essential for tasks involving larger, heavier components.

Industry-Specific Innovations and Applications

KUKA’s new KR SCARA models are set to revolutionize various industries due to their enhanced capabilities and innovative designs. The electronics and automotive industries, in particular, stand to benefit significantly from these advancements.

Electronics Industry: Precision and Speed

In the electronics industry, where precision and speed are paramount, the KR SCARA series has proven especially effective. The KR SCARA robots offer ISO Class 5 certification for cleanliness and safety, along with ESD protection, making them ideal for tasks such as 3C, PCB assembly, soldering applications, and automotive electronics. The combination of high precision and rapid performance ensures that these robots meet industry demands efficiently. By reducing the margin for error and increasing production speed, KUKA’s robots help electronics manufacturers achieve higher outputs without compromising on quality. The KR SCARA models are particularly beneficial for delicate tasks that require utmost precision, such as soldering tiny components onto PCBs. Their ability to maintain consistent performance in cleanroom environments further enhances their utility in this sector.

Automotive Industry: Cost-Effective Solutions

The automotive industry, known for its high cost pressures and the critical need to avoid downtime, stands to gain significantly from the KR series robots. Small parts assembly and material handling are specific applications where these robots can enhance production efficiency. By minimizing the requirement for human intervention and maximizing uptime, KUKA’s robots help in maintaining consistent production workflows. This not only reduces operational costs but also mitigates the risks associated with manual handling errors. The KR SCARA robots contribute to a more streamlined and efficient production process, which is crucial in an industry where even minor disruptions can lead to substantial profit losses. Their high reliability and precision help maintain the quality of assembly tasks, ensuring that the final products meet stringent industry standards.

Broadening Horizons with Hygienic Designs

KUKA has also recognized the need for specialized robotics in the food industry, introducing a hygienic oil series within the KR SCARA lineup. This strategic move underscores KUKA’s commitment to diversifying its applications while maintaining high performance and regulatory compliance.

Food Industry: Meeting Hygiene Standards

The introduction of the hygienic oil series, designed exclusively for the food industry, showcases KUKA’s dedication to meeting stringent hygiene standards critical in food production environments. These models utilize food-grade lubricants, ensuring that they comply with the rigorous hygiene requirements of the sector. By incorporating these specialized features, KUKA enables food manufacturers to integrate advanced robotic solutions into their production lines without compromising cleanliness or safety. This development is particularly significant as it allows for the automation of processes that were previously challenging to automate due to stringent hygiene standards. The result is a more efficient and streamlined production process that maintains the highest standards of food safety.

Enhanced Flexibility Across Models

Beyond the KR 20 and KR 60, the KR SCARA series includes models with 6 kg, 12 kg, and 13 kg payload options. The 13 kg variant is part of the hygienic oil series, explicitly developed to fulfill the unique needs of the food industry. These options offer high precision, speed, and flexibility, ensuring that businesses can find the right robot configuration for their specific needs. This flexibility allows businesses to tailor their automation solutions to their operational requirements, enhancing overall efficiency and productivity. The availability of different payload options also means that the KR SCARA series can be used across various stages of the production process, from handling raw materials to packaging finished products.

Simplified Integration and Advanced Design Features

One of the hallmarks of the new KR SCARA models is their advanced design, which simplifies installation and integration. These features make it easier to incorporate the robots into existing setups, reducing downtime and facilitating smoother transitions.

Innovative Design for Easy Installation

The innovative design of the KR SCARA models significantly simplifies their installation process, making them an attractive option for businesses looking to upgrade or enhance their automation systems. The KR 20, for example, features a cable connector plate on top of the A2 axis, which streamlines the integration process, reducing the time and effort required for setup. Similarly, the KR 60’s design eliminates the need for steel structure mounting or planar referencing, further simplifying its installation. These design features not only make the robots easier to set up but also ensure that they can be seamlessly integrated into existing systems, minimizing disruption to ongoing operations.

Reliability and Scalability in Production

KUKA’s strategic enhancements emphasize reliability and scalability, crucial for evolving production landscapes. The new models are not only more versatile but also designed for long-term durability, ensuring they can withstand rigorous operational demands. This focus on robust design enhances their appeal across various industries, setting new standards in manufacturing robotics. The durability and reliability of the KR SCARA models mean that businesses can rely on them for consistent performance over extended periods, reducing the need for frequent maintenance or replacements. This scalability ensures that as businesses grow and their production demands increase, their KUKA robots can adapt and continue to deliver optimal performance.

Addressing the Multifaceted Challenges of Modern Production

The expansion of the KR SCARA series aligns with broader trends in the robotics industry, which increasingly emphasizes handling complex and varied tasks without compromising accuracy or speed. This adaptability is crucial as industries continuously evolve, requiring automation solutions that can keep pace with changing demands.

Adapting to Rapidly Evolving Industrial Needs

As industries evolve and their production needs become more complex, the demand for versatile and adaptable automation solutions increases. KUKA’s expansion of the KR SCARA series addresses this need by providing robots capable of handling a wide range of tasks with high precision and speed. This adaptability is particularly important in industries like electronics and automotive, where production processes are frequently updated to meet new standards and technological advancements. By offering robots that can adapt to these changes with ease, KUKA ensures that businesses can maintain high levels of efficiency and productivity even as their operational requirements evolve.

Anticipating Future Demands

KUKA, a leading name in robotics and automation, has significantly enhanced its KR SCARA robot series by launching the KR 20 and KR 60 models. These advanced robots are capable of handling heavier payloads, enhancing overall productivity and efficiency. They are engineered to maintain high levels of precision and versatility, making them an ideal fit for a range of production environments. One of their key features is their seamless integration into modern manufacturing systems, which is crucial for industries striving for greater efficiency and cost-effectiveness.

As industries place increasing emphasis on optimizing production processes, KUKA’s innovative KR 20 and KR 60 robots stand out as potential game-changers. These models promise not just high performance but also reliability in operations, providing businesses with a competitive edge. Their design is aimed at addressing common challenges in industrial automation, such as maintaining consistent quality while scaling up production.

With these new additions to the KR SCARA series, KUKA continues to cement its position as a pioneer in robotic technology, offering solutions that meet the evolving demands of contemporary industries.