The imperative for industrial DevOps has never been more critical as the manufacturing sector grapples with the increasing complexity and downtime associated with industrial coding errors. A recent survey conducted by Copia Automation involving 200 executives from organizations, each with revenues surpassing $350 million, sheds light on the significant financial and operational impacts these errors impose. Manufacturing firms face an average shutdown time of 31 hours due to coding errors, with each hour costing approximately $4.2 million, summing up to a staggering $126 million per shutdown. These findings underscore the urgent need for robust DevOps practices to mitigate downtime and enhance operational efficiency.

The Major Contributors to Unplanned Downtime

Cybersecurity Breaches and Hardware Malfunctions

Unplanned downtime in industrial settings is predominantly driven by several critical factors, prominently including cybersecurity breaches and hardware malfunctions. The survey indicates that 47% of unplanned downtime incidents stem from cybersecurity breaches. As manufacturing processes increasingly become digitized, the vulnerability to cyber-attacks has amplified, posing a significant risk to continuous operations. Malicious infiltrations can sabotage systems, steal sensitive data, and lead to prolonged shutdowns while systems are secured and restored. This emphasizes the necessity for robust cybersecurity measures and continuous monitoring to preempt and neutralize potential threats before they can cause substantial operational disruptions.

Equally concerning, hardware malfunctions account for 45% of unplanned downtimes, as revealed by the survey. The reliability of physical components is paramount, and any failure in machinery can halt production lines, leading to significant financial losses. Regular maintenance, timely upgrades, and stringent quality checks of hardware components are essential strategies to mitigate such risks. The importance of predictive maintenance is accentuated here, leveraging data analytics to foresee potential hardware failures and address them proactively. This transition from reactive to predictive maintenance can significantly enhance uptime and operational efficiency.

Coding and Software Issues

Another vital factor contributing to unplanned downtime in industrial settings is coding and software issues, which accounted for 41% of incidents, according to the survey. Coding errors can lead to malfunctioning equipment, incorrect data processing, and overall system failures, all of which can cause production halts and financial losses. These errors are particularly prevalent in programmable logic controllers (PLCs), which are integral to the automation of industrial processes. Yet, despite the critical role PLCs play, visibility into their code is often limited, making it challenging to identify and rectify errors promptly.

The survey’s findings also highlight a troubling reliance on temporary fixes to expedite the restoration of operations rather than delving into and resolving the root causes of the issues. Such an approach may provide immediate relief but inevitably leads to the recurrence of the same problems, perpetuating a cycle of repeated failures and disruptions. This practice underscores the pressing need for a more systematic approach to DevOps, wherein thorough code reviews and comprehensive debugging are prioritized. Despite 99% of the respondents implementing code review processes, their inefficacy is evident as organizations spend ten times more hours debugging code than reviewing it, indicating a gap in the effectiveness of current practices.

Barriers to DevOps Adoption

Competing Priorities and Managerial Indifference

Despite the considerable awareness of industrial DevOps, with an impressive 97% of survey respondents recognizing its importance, several hurdles impede its widespread adoption. One notable barrier is the presence of competing priorities within organizations, cited by 44% of the respondents. In the fast-paced manufacturing environment, numerous initiatives vie for attention and resources, which can lead to the deprioritization of DevOps practices. Short-term objectives often eclipse long-term strategic investments, which are essential for fostering a robust DevOps culture. This challenge is compounded by the limited immediacy of the benefits of DevOps, which may not be as apparent as those yielded by other operational improvements.

Managerial interest, or the lack thereof, is another significant impediment, affecting 39% of the organizations surveyed. Effective DevOps implementation requires enthusiastic advocacy from top management to ensure adequate allocation of resources and sustained focus on strategic initiatives. Without the buy-in of executive leadership, it becomes challenging to drive cultural change and integrate DevOps seamlessly into the industrial workflow. This managerial indifference often stems from a lack of understanding of the long-term benefits of DevOps, which can include enhanced operational efficiency, reduced downtime, and improved product quality. Therefore, educating and engaging managerial personnel about these advantages is critical for overcoming this barrier.

The Role of Artificial Intelligence and Edge Computing

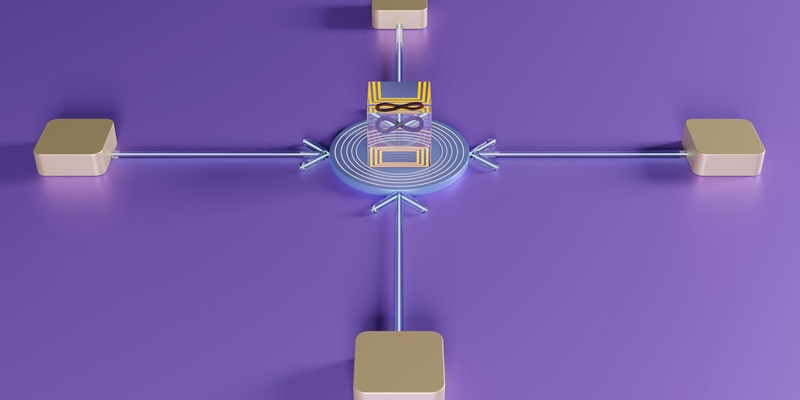

Looking towards future trends, the deployment of artificial intelligence (AI) on industrial platforms emerges as a significant focal point. AI models, when properly integrated, possess the capability to revolutionize industrial operations by providing predictive maintenance insights, optimizing resource allocation, and enhancing decision-making processes. However, the effective deployment of AI necessitates a strong DevOps foundation to ensure smooth and programmatic deployment. AI-driven systems require continuous integration and delivery practices to rapidly adapt to new data and operational requirements, which underscores the need for robust DevOps practices.

Edge computing is poised to play a pivotal role in the evolution of industrial DevOps, as more workloads are anticipated to migrate to edge platforms instead of traditional cloud infrastructures. Edge computing brings computation and data storage closer to the sources of data generation, offering lower latency and real-time processing capabilities essential for industrial operations. As this transition unfolds, the importance of DevOps will be magnified at the edge to manage the growing complexity and ensure the seamless operation of edge devices and applications. This shift will demand a structured and systematic approach to DevOps to manage the expanse of edge and AI applications effectively.

The Future of Industrial DevOps

A Sector at a Crossroads

The current landscape of industrial DevOps is marked by a pressing awareness of its significance but hampered by organizational challenges and a propensity for quick fixes. As the complexity of industrial platforms continues to rise, the need for a more structured and systematic approach to DevOps is undeniable. The potential efficiencies and improvements that can be realized through enhanced DevOps practices are substantial, offering a pathway to significantly reduce downtime, improve operational efficiency, and optimize resource utilization.

The survey results indicate a sector at a crossroads, wherein the choice to adopt and embed robust DevOps practices can drive transformative change. However, this change demands overcoming several entrenched hurdles, including shifting organizational priorities and garnering executive buy-in. The integration of AI and edge computing further cements the need for a solid DevOps foundation, emphasizing the interdependence of technological advancement and systematic operational practices.

Moving Towards Improved Practices

The urgency for industrial DevOps in the manufacturing sector is at an all-time high, primarily due to the escalating complexity and downtime linked to industrial coding errors. A recent survey by Copia Automation, which included 200 executives from companies with annual revenues exceeding $350 million, highlights the severe financial and operational repercussions of these errors. On average, manufacturing plants experience a shutdown duration of 31 hours due to coding errors. Each hour of downtime incurs a substantial cost of around $4.2 million, leading to an overwhelming $126 million in losses per incident. These figures illustrate the pressing need for effective DevOps strategies to reduce downtime and boost operational efficiency. Implementing robust DevOps practices can help identify and rectify errors more quickly, thereby minimizing financial losses and operational disruptions. As the manufacturing industry evolves, integrating DevOps can serve as a pivotal approach to overcoming the challenges posed by industrial automation and coding complexities.