Introduction to Brainless Robotics

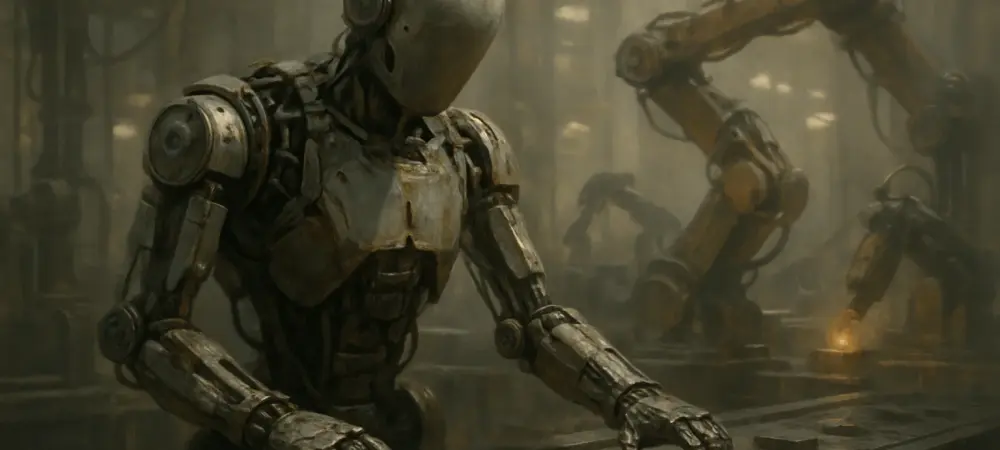

In a world where robotics often conjures images of intricate circuits and advanced artificial intelligence, a surprising innovation has emerged that challenges this norm by stripping robots down to their most basic mechanical essence, offering new possibilities for automation. Researchers have developed a new type of robot that operates without electronic brains or complex sensors, relying instead on simple materials like rubber bands and motors to perform tasks. This development raises intriguing possibilities for automating mundane activities with minimal cost and complexity, potentially transforming industries that prioritize efficiency over sophistication. The significance of such an approach lies in its accessibility, offering a solution that could democratize robotics for small-scale operations or resource-limited environments. By focusing on mechanical design rather than digital programming, this technology addresses a critical need for affordable automation tools. The purpose of this FAQ is to explore the key aspects of these so-called “brainless” robots, answering pressing questions about their functionality, applications, and future potential.

Readers can expect a comprehensive breakdown of how these robots work, their advantages over traditional systems, and the limitations they face in broader contexts. This discussion aims to provide clarity on whether such innovations can truly redefine simple task automation. Through targeted questions and detailed insights, the content will guide understanding of this minimalist yet impactful approach to robotics.

Key Questions About Brainless Robots

What Are Brainless Robots and How Do They Work?

Brainless robots represent a novel category of robotic systems that function without electronic control units, sensors, or advanced computing. Instead, their “intelligence” is embedded in physical design elements such as geometry, material properties, and mechanical components like rubber bands. Developed by a team at a leading engineering institution, these robots use a motor and strategically placed elastic bands to navigate environments and execute basic tasks, such as sorting objects based on mass.

The core principle behind their operation is mechanical feedback, where physical interactions with the environment trigger predefined responses. For instance, mechanical antennae act as feelers, detecting obstacles and prompting the robot to adjust its path via motor activation influenced by rubber band tension. This simplicity eliminates the need for costly digital systems, making the technology a viable option for straightforward automation needs while showcasing how form can effectively dictate function.

Why Focus on Mechanical Programming Over Electronic Systems?

The shift toward mechanical programming in robotics stems from a need to reduce costs and complexity in certain applications where high-tech solutions may be overkill. Electronic systems, while powerful, often require significant investment in hardware, software, and maintenance, which can be prohibitive for small businesses or specific niche tasks. Brainless robots, by contrast, leverage physical properties to achieve similar outcomes at a fraction of the expense, addressing a gap in the market for low-budget automation.

This approach also offers resilience in environments where electronic components might fail due to harsh conditions like extreme temperatures or dust. By relying on durable materials and basic mechanics, these robots ensure reliability without the fragility of circuit-based designs. The emphasis on mechanical intelligence highlights a broader trend in engineering to explore alternative methods of control, potentially complementing rather than replacing electronic systems in the robotic landscape.

What Tasks Can Brainless Robots Perform Effectively?

Brainless robots are best suited for repetitive, simple tasks that do not require complex decision-making or adaptability to dynamic environments. Examples include sorting objects by weight or size in a controlled setting, navigating predefined mazes, or moving items along a fixed path. Their design allows for such activities to be executed with minimal setup, as the robot’s actions are predetermined by its physical configuration rather than real-time data processing.

While limited in scope compared to AI-driven robots, their strength lies in cost-efficiency and ease of customization. Adjusting the placement or tension of rubber bands can alter the robot’s behavior to suit different purposes, providing flexibility within their niche. This makes them particularly appealing for industries like manufacturing or logistics, where basic automation can streamline operations without the overhead of sophisticated technology.

What Are the Limitations of Brainless Robots?

Despite their innovative design, brainless robots face significant constraints that restrict their applicability to a narrow range of scenarios. Their lack of electronic processing means they cannot adapt to unexpected changes or handle tasks requiring nuanced judgment, such as responding to varied environmental inputs beyond pre-set mechanical triggers. This rigidity limits their use in complex or unpredictable settings where adaptability is crucial.

Additionally, the current prototypes exhibit restricted capabilities in terms of speed and versatility. While they perform well in controlled, simple tasks, scaling up their functionality to include faster operations or more intricate actions remains a challenge. These limitations suggest that while they hold promise for specific use cases, they are not positioned to replace more advanced robotic systems in the broader market.

What Does the Future Hold for Mechanical Robotics?

Looking ahead, the potential for brainless robots lies in refining their design to enhance performance while maintaining simplicity. Researchers are exploring additional physical properties, such as spring compression or shape-memory alloys, to expand the range of tasks these robots can undertake. Innovations in actuation sources could also improve speed and introduce capabilities like jumping over obstacles, broadening their practical utility. Another promising direction is the development of hybrid systems that integrate minimal electronic components with mechanical programming. Such combinations could offer a balance between cost-effectiveness and enhanced functionality, extending battery life and efficiency. Over the next few years, from 2025 onward, advancements in this field may position brainless robots as a staple in low-cost automation, particularly for industries seeking sustainable and accessible solutions.

Summary of Key Insights

This exploration into brainless robots underscores their unique role in the realm of automation, emphasizing simplicity and affordability as core strengths. These systems, driven by mechanical feedback through materials like rubber bands, effectively handle basic tasks such as sorting and navigation without the need for expensive electronic controls. Their design philosophy of embedding intelligence in physical form offers a refreshing contrast to conventional robotics, prioritizing accessibility over complexity. Key takeaways include their suitability for niche applications, the cost benefits of mechanical programming, and the current limitations in adaptability and speed. The potential for future enhancements, including hybrid models and new actuation methods, suggests a growing relevance for these robots in specific sectors. For those interested in delving deeper, resources on mechanical engineering innovations and robotics design trends are recommended for further exploration.

Final Thoughts on Brainless Robotics

Reflecting on the journey of brainless robots, it becomes evident that their development marks a pivotal shift in how automation is perceived, challenging the reliance on high-tech solutions for every problem. Their success in demonstrating that basic tasks can be managed through mechanical means alone inspires a reevaluation of design priorities in robotics. This shift highlights the value of returning to fundamental principles to solve modern challenges. As a next step, stakeholders in industries like manufacturing or education are encouraged to consider pilot programs testing these robots for repetitive tasks, assessing their fit within existing workflows. Exploring partnerships with engineering teams to customize designs for specific needs could unlock untapped potential. Ultimately, the conversation around brainless robots prompts a broader consideration of balancing simplicity with innovation, urging a thoughtful approach to integrating such technologies into practical applications.