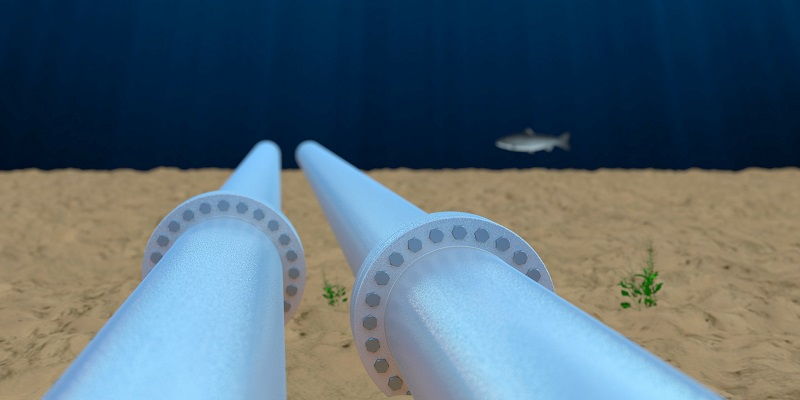

Over the past few years, the University of Houston (UH) has been at the forefront of pioneering research in the field of subsea inspections. In a significant development, UH researchers have created an autonomous robot capable of detecting probable pipeline leaks and structural failures during subsea inspections. This breakthrough technology holds the potential to revolutionize the inspection process, making it considerably safer and more cost-effective.

Advantages of the technology

The newly developed autonomous robot brings numerous advantages to the subsea inspection process. First and foremost, it enhances safety by eliminating the need for human divers to inspect potential dangers. The robot’s ability to identify pipeline leaks and structural failures in real-time significantly reduces the risk of major oil spills, which can be catastrophic for both the environment and the companies responsible for the maintenance of subsea infrastructure. By protecting vulnerable ecosystems, timely inspections add a crucial layer of environmental protection.

SmartTouch Technology

At the core of this innovative subsea inspection technology is the SmartTouch system developed by UH researchers. The SmartTouch technology equips Remote Operated Vehicles (ROVs) with multiple stress wave-based smart touch sensors, video cameras, and scanning sonars. These sensors work in tandem to detect and evaluate the integrity of subsea structures, enabling the autonomous robot to accurately identify potential pipeline leaks and structural failures. The combination of these different components provides a holistic and comprehensive approach to subsea inspections.

Funding and support

Recognizing the potential impact of this technology, the Bureau of Safety and Environmental Enforcement (BSEE) has awarded UH researchers a substantial grant of $960,493 for further development and refinement of the autonomous robot. Additionally, UH researchers are collaborating with industry leaders Oceaneering International and Chevron to harness their expertise and resources in order to expedite the commercialization of the technology. This support and partnership are crucial in turning the research into a practical solution for the subsea industry.

Benefits of Automation

By automating the subsea inspection process, UH researchers aim to significantly reduce both the cost and the risks associated with inspections. Manual inspections often involve extensive human labor, which can be time-consuming and expensive. Furthermore, the risks involved in sending divers into potentially hazardous environments are immense. With the autonomous robot, not only can inspections be conducted more efficiently, but they also remove the inherent danger faced by human divers, leading to safer operations.

Validation of the method

To ensure the effectiveness and reliability of the proposed method for assessing the looseness of subsea bolted connections, UH researchers conducted trials that yielded promising results. The trials validated the accuracy of the SmartTouch technology in identifying and evaluating subsea bolted connections, a critical aspect of subsea infrastructure stability. By accurately assessing the condition of these connections, the risks of structural failures can be minimized, preventing potential catastrophic events.

Environmental Impact

Corrosion is identified as the primary cause of most small leaks in subsea infrastructure. These leaks, although seemingly insignificant individually, can have devastating consequences for the environment. The SmartTouch technology, with its ability to detect and address pipeline leaks promptly, can prevent these leaks from escalating into larger, more significant incidents. By doing so, it safeguards marine ecosystems and protects delicate and vulnerable habitats that could be severely impacted by oil spills.

Future Applications

The potential applications of the SmartTouch sensing system extend far beyond pipeline inspections. This groundbreaking technology opens doors for examining various types of subsea structures, including platforms, risers, and support elements. The versatility of the system presents an opportunity to push the boundaries of robotics and structural health monitoring technologies. With further development and refinement, the SmartTouch technology can enhance the overall integrity and safety of subsea infrastructure, ensuring its long-term sustainability.

The development of an autonomous robot capable of detecting subsea pipeline leaks and structural failures is a significant step forward in the field of subsea inspections. The research conducted by the University of Houston, generously supported by the BSEE and industry leaders like Oceaneering International and Chevron, has paved the way for safer and more cost-effective inspections. By leveraging SmartTouch technology, the subsea industry can enhance the protection of the environment, prevent major oil spills, and ensure the structural integrity of critical subsea infrastructure. With ongoing development and implementation, it is poised to revolutionize the way inspections are conducted, ultimately leading to a more sustainable marine ecosystem.