The aviation industry has been moving towards reducing weight, improving quality, and lowering costs for decades. One way to achieve that is by using robotics in manufacturing airline components. Q5D Technologies, a UK-based company, has partnered with the University of Sheffield AMRC to embark on a £1.7m ($2.1m) project called LiveWire. The project aims to add embedded wiring into airline seating components and control systems, automating the process, and reducing human error.

The Project LiveWire

Q5D’s LiveWire project is an innovative initiative that focuses on streamlining manufacturing procedures within the aviation industry. The project’s primary objective is to automate the production process of manufacturing airline seating components, thereby reducing operating costs and enhancing the quality of the components. The use of robotics in LiveWire enables the automation of the wiring process, which currently requires manual labor, as robots have higher accuracy rates than manual handling.

Existing wiring problems

The wiring process in aircraft, cars, and other consumer electronics goods is currently done manually by human operators. The manual process is prone to human errors that could lead to failures or even fires. The damage that results from such mishaps is not only expensive to fix, but could lead to catastrophic accidents. The LiveWire project comes as a solution to such issues, with its robots eliminating human error and significantly lowering the chances of accidents.

Q5D’s Robotics Tool

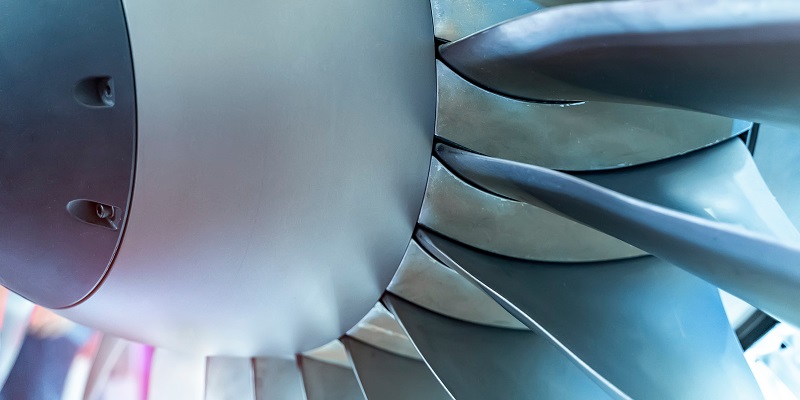

Q5D’s LiveWire project features a 5-axis robotic tool that can handle intricate and complex-shaped components. The robotic tool can add wiring to the components with greater accuracy, resulting in lighter, higher-quality components. The addition of wiring also improves the reliability and longevity of the components.

AMRC’s Contribution

The University of Sheffield AMRC played a significant role in the development of the LiveWire project. AMRC’s primary task was to develop a proof-of-concept solution to automate the process of embedding wiring into airline seating components and control systems. The solution calculates the position and rotation of the components, which enables the robot to fully automate the wiring process.

Automation with a vision system

The use of a vision system to automate the robot path was a critical component of the LiveWire project. The benefits of automating the system using a vision system provided Q5D’s robotic technology with greater flexibility in adapting to dynamic environments. The automatic adjustments to the robotic path improved productivity by reducing the manual programming required for readjusting the tool path.

Inspection of wiring with a computer vision system

The AMRC implemented proof-of-concept computer vision solutions to automate the inspection of wiring. An automated system was developed that could identify any defects or imperfections in the wiring process. The use of robotics and computer vision systems to automate the wiring and inspection process offers significant advantages over traditional manual handling methods.

Funding and Collaboration

The LiveWire project received funding from Innovate UK as part of the ATI program. The University of Sheffield AMRC and other companies collaborated on the project. With their combined expertise, they were able to tackle complex issues and develop innovative solutions, which drove the project to completion.

Transferability of the concept

The success of the LiveWire project has made it possible to transfer the concept and methodology to other robotics automation systems. The technology could be used in other industries outside the aviation sector, such as the automotive industry, where robotics can automate wiring processes.

In conclusion, the LiveWire project developed by Q5D Technologies and the University of Sheffield AMRC is an innovative solution to a long-standing challenge in the aviation industry. The project’s success in automating the airline seating components and control systems wiring process has immense potential to revolutionize manufacturing processes across various industries. With funding from Innovate UK and collaboration between companies, the LiveWire project has set the pace for the use of robotics and vision systems in manufacturing processes.