The manufacturing landscape in the Asia-Pacific (APAC) region is undergoing rapid transformation, playing a pivotal role in the economic growth of the region. As the world’s largest manufacturing hotspot, APAC is expected to witness significant advancements in its connected manufacturing industry. This article delves into the forecasts, factors, and opportunities shaping APAC’s manufacturing sector.

Growth and Forecast of the Connected Manufacturing Industry in APAC

APAC’s manufacturing industry has been thriving, and it is projected that by 2025, the region’s connected manufacturing industry will be worth a staggering $54 billion. The growth trajectory remains promising, with estimations pointing towards a value exceeding $80 billion by 2029. The rising investments and technological advancements in APAC countries are driving this substantial expansion.

Strong Growth of Private 5G Network Revenue in APAC

Among the developing markets in APAC, private 5G network revenue from manufacturing is predicted to experience the strongest growth between 2022 and 2030, with a remarkable compound annual growth rate (CAGR) of over 45%. This growth rate surpasses that of North America and Europe, signifying APAC’s leadership in embracing cutting-edge technologies.

Influence of industrial superpowers in APAC

China, South Korea, and Japan, being the industrial superpowers of APAC, have set the stage for the region’s positive manufacturing future. These countries have introduced national incentives that encourage the digitalization of smaller APAC nations. By fostering innovation and technological adoption, these industrial giants are creating a favorable ecosystem for growth in the manufacturing sector.

Rise in Greenfield Manufacturing Facilities in Developing Markets

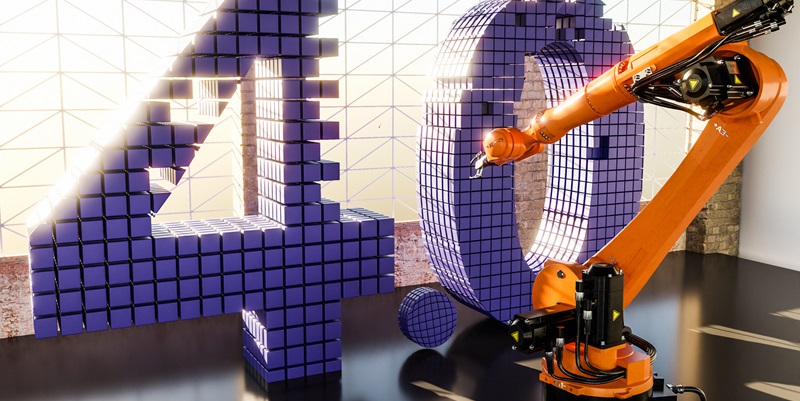

Developing markets in APAC are witnessing a surge in greenfield manufacturing facilities. Compared to older technology, these markets recognize the advantages of Industry 4.0 solutions, offering advanced automation, data exchange, and smart manufacturing processes. The appeal of newer technology further propels the region towards digital transformation.

Shift towards Smart Manufacturing in Asian Nations

The escalation of labor costs in Europe and North America, coupled with the need for technological improvements and customization, has emerged as a driving force behind the shift towards smart manufacturing in Asian nations. To retain competitiveness, APAC countries are leveraging automation, artificial intelligence, and real-time data analytics to enhance productivity, efficiency, and product quality.

Popularity of India as an Alternative for High-Value Manufacturing

India is gaining prominence as an alternative for high-value manufacturing, especially as global companies seek to reduce their reliance on China. A notable example is Foxconn’s billion-dollar investment in India, driven by Apple’s initiative. This move not only highlights India’s allure as a manufacturing hub but also signifies the increasing popularity of the nation in attracting high-value manufacturing projects.

Impact of India’s Digitalization and Standalone 5G Deployment

India’s significant strides in digitization and its deployment of standalone (SA) 5G networks are expected to foster increased engagement with Industry 4.0 initiatives. The country has already launched an Industry 4.0 initiative and a comprehensive incentive scheme aimed at promoting domestic smartphone production. Such efforts are likely to accelerate the adoption of advanced manufacturing technologies across various sectors.

Southeast Asian Markets Catching Up with Factory Transformation

Countries such as Malaysia, Singapore, and Vietnam in Southeast Asia are rapidly catching up to the global trend of factory transformation. These nations are becoming avid adopters of intelligent manufacturing practices, investing in automation, robotics, and advanced analytics to enhance production efficiency and competitiveness. By embracing digitalization, Southeast Asia is poised to become a manufacturing powerhouse in the region.

The manufacturing landscape in APAC is undergoing rapid transformation, driven by advancements in technology and a greater emphasis on digitalization. The region’s connected manufacturing industry is set to experience exponential growth, with estimates pointing towards a worth of over $80 billion by 2029. With industrial superpowers like China, Japan, and South Korea leading the way, and developing markets embracing smart manufacturing, APAC is on track to strengthen its position as a global manufacturing hub. It is evident that embracing Industry 4.0 initiatives and capitalizing on digital transformation will be crucial for sustained economic growth in the region.