In today’s fast-paced and demand-driven world, the electronics manufacturing industry is rapidly evolving. With consumers expecting more advanced and personalized products, manufacturers must keep up by optimizing their processes and enhancing innovation. Enter artificial intelligence (AI) and robotics, transformative technologies that are revolutionizing how electronics are designed, produced, and delivered. The integration of these technologies is reshaping the industry in manifold ways, addressing pervasive challenges and meeting rising demands. This comprehensive analysis delves into how AI and robotics streamline operations and enhance productivity in electronics manufacturing, ultimately positioning companies for sustained growth and competitiveness.

Optimizing the Design Phase with AI

Leveraging AI’s predictive capabilities during the design phase can significantly streamline the development of electronics. By analyzing numerous variables in a short duration, AI enables optimized component performance and more efficient designs. A notable example is Nvidia’s employment of AI to engineer circuits for GPUs that reduce space usage by 25% without compromising performance. This reduction in space translates to more compact and powerful electronics, a critical aspect in an industry where miniaturization is paramount.

Machine learning, a subset of AI, further enriches product blueprints by evaluating past designs and testing new human-generated concepts. This approach expedites research and development processes, leading to quicker product launches and fostering continuous innovation. By harnessing historical data, AI can highlight successful design patterns and recommend modifications that might not be apparent through traditional methods. This capability ensures manufacturers stay ahead of market trends, consistently delivering products that meet high-performance benchmarks and aesthetic standards.

Facilitating Innovative and Complex Products

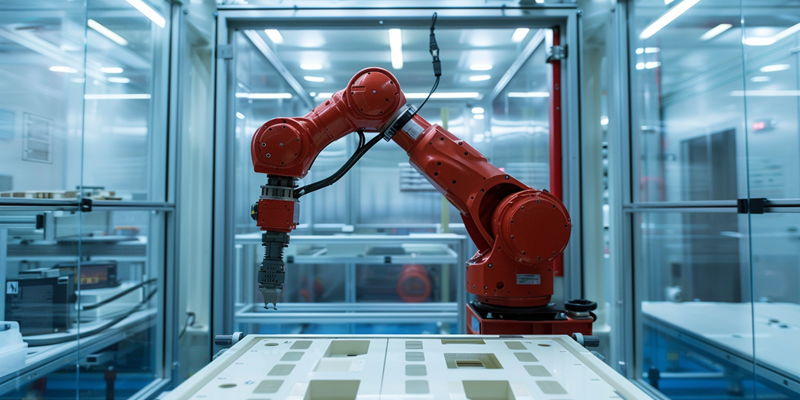

The precision offered by AI and robotics facilitates the production of innovative and previously unfeasible products. Robotics, for instance, enable the assembly of smaller, more compact components, aligning with the industry’s shift towards miniaturization. This assembly precision is crucial for developing intricate designs without compromising efficiency or structural integrity. As a result, manufacturers can push the boundaries of what is technologically possible, delivering more sophisticated and high-performing electronics.

Technologies such as additive manufacturing (3D printing) and multi-axis micromachining robots amplify this capability by allowing the production of detailed and precise components more rapidly than traditional methods could. Additive manufacturing enhances the creation of complex geometries, while micromachining robots ensure the fine details are rendered with impeccable accuracy. Together, these technologies drive innovation, enabling manufacturers to realize complex product designs and bring them to market faster.

Securing and Streamlining Supply Chains

AI plays a crucial role in securing and streamlining supply chains by offering optimal sourcing strategies and alerting manufacturers to potential disruptions. In a global market where supply chain issues can drastically affect production schedules and profitability, predictive analytics provide pivotal benefits. AI can predict disruptions by analyzing vast data sets from multiple sources, including political climates, natural disasters, and market trends. By identifying potential bottlenecks, manufacturers can proactively switch to alternative suppliers, ensuring resource availability and uninterrupted production cycles.

Predictive analytics powered by AI also provide early warnings about potential material shortages or delays, allowing manufacturers to adjust their orders proactively. This information minimizes the risk of costly production halts and helps maintain a smooth production flow. This proactive approach not only safeguards against disruption but also fosters a more resilient supply chain capable of adapting to unforeseen challenges swiftly.

Boosting Production Throughput

To meet the escalating demand for electronics, automating inefficient processes throughout the production line becomes essential. Robotics excel in handling repetitive tasks like assembly and part picking, performing these functions much more efficiently than human workers could. This efficiency frees human workers to focus on more complex and strategic roles, thus enhancing overall productivity and ensuring higher quality outputs.

Moreover, automating the quality control process through machine vision systems maintains the pace of high-speed production without sacrificing inspection accuracy. For example, Lenovo has successfully implemented AI to significantly reduce its production schedules, thereby boosting overall output. Such applications of AI and robotics streamline operations and are instrumental in meeting the growing demand for high-quality electronics in a timely manner.

Promoting Sustainability in Manufacturing

While the implementation of AI and robotics may initially increase energy consumption, their long-term benefits significantly enhance sustainability. Through refined throughput and reduced error margins, these technologies lower the relative energy consumption per product. AI-driven process optimization fine-tunes manufacturing processes for maximum efficiency, translating into substantial energy savings and reduced carbon emissions over time.

Furthermore, machine learning contributes to sustainability by analyzing supply chains and product designs to identify opportunities for using fewer raw materials and adopting eco-friendly transportation methods. These insights guide manufacturers towards more sustainable practices, matching the increasing consumer demand for environmentally responsible products. By integrating AI and robotics, manufacturers can achieve a balance between technological advancement and environmental stewardship.

Adapting to Market Changes with Agility

In today’s fast-paced, demand-driven world, the electronics manufacturing industry is evolving at an unprecedented rate. Consumers expect more advanced and personalized products, pushing manufacturers to optimize their processes and fuel innovation constantly. This is where artificial intelligence (AI) and robotics come into play, acting as game-changers in how electronics are designed, manufactured, and delivered. The adoption of these transformative technologies is overhauling the industry in many ways, tackling widespread challenges and meeting escalating consumer demands. AI and robotics streamline operations, improve productivity, and significantly enhance efficiencies in electronics manufacturing. They enable predictive maintenance, yield optimization, and supply chain automation, ensuring high-quality products reach the market faster. As a result, companies leveraging these technologies are better positioned for sustained growth and enhanced competitiveness. This comprehensive examination explores how AI and robotics propel the industry forward, revolutionizing traditional manufacturing paradigms and setting new benchmarks for excellence.