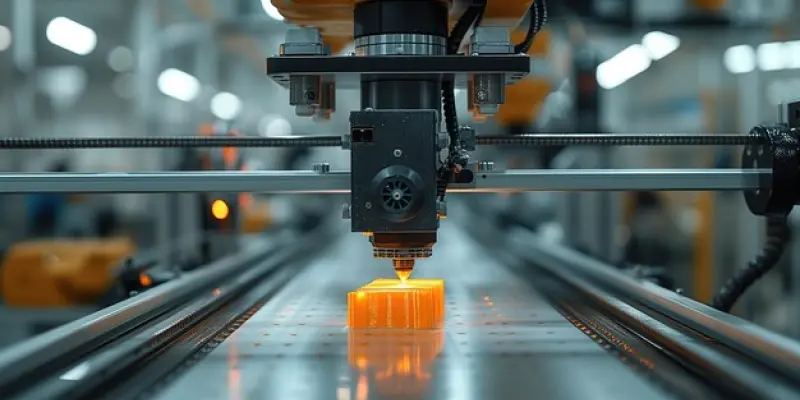

The innovative landscape of 3D printing has expanded beyond traditional applications, with groundbreaking initiatives that leverage this technology to tackle both environmental and technological challenges. A pivotal advancement in recent years involves converting plastic waste into 3D printing filament, offering a sustainable solution for excessive plastic accumulation. This transformation not only aids in alleviating the environmental impact of waste but also enhances industrial manufacturing processes. Additionally, 3D printing has facilitated the emergence of robots that operate independently from traditional electronics, paving the way for the development of versatile, durable systems suitable for a variety of applications. These technological advancements underscore a significant shift toward sustainable practices, propelling industries into a future where innovation and environmental responsibility coexist harmoniously.

From Plastic Waste to High-Performance Filament

Converting Plastic Waste

Researchers at institutions in Germany have pioneered techniques to transform polypropylene waste found in household packaging into high-purity 3D printing filament, reflecting a growing trend of ecological responsibility in manufacturing. This process not only addresses the issues associated with the generation of millions of metric tons of plastic waste annually but also provides industries with a durable material suitable for sectors such as automotive and aerospace. By repurposing waste, these initiatives contribute to the reduction of environmental pollution, demonstrating a practical approach to sustainability. The adoption of these biodegradable materials in 3D printing signifies an important step toward minimizing the reliance on virgin materials, stressing the importance of resource efficiency in production.

Application in Industrial Manufacturing

Utilizing plastic waste for manufacturing 3D printing filament offers industries an eco-friendly alternative to traditional materials while maintaining strong material properties. This development has already seen integration into various sectors, showcasing potential to advance manufacturing with a reduced environmental footprint. The aerospace and automotive industries have particularly benefited from these robust materials, which are being researched for their capability to withstand extreme conditions while adhering to rigorous safety standards. As these industries move toward sustainable practices, the utilization of such recycled materials becomes a crucial aspect of their operations. The collaboration between environmental initiatives and industrial manufacturing illustrates the adaptive potential of 3D printing to meet diverse market demands.

Transformative Robotic Systems

Electronic-Free Robotics

In the United States, the Bioinspired Robotics Lab at the University of California, San Diego, has made breakthroughs in developing electronic-free robotic systems using 3D printing technologies. These robots, characterized by their unique six-legged design, operate with compressed gas, eliminating the need for traditional electronic components. By sidestepping the limitations of electronic-based systems, these robots find applications in extreme and hazardous environments, overcoming barriers posed by high temperatures, radiation, or unpredictable terrain. This innovation enables continuous operation in conditions that would typically impair electronic devices, offering possibilities for practical deployment in exploration, disaster response, and industrial inspection scenarios.

Advantages and Implications

The development and utilization of robots devoid of electronics peek into the future of robotics, where minimalistic, efficient designs offer versatile solutions for various operational contexts. The absence of delicate electronic parts increases the robustness of these machines, extending their usable lifespan and reducing the frequency of maintenance interventions. Furthermore, these advancements suggest broader implications for reducing electronic waste, presenting a more straightforward disposal or recycling process when the systems reach the end of their life cycle. Electronic-free robotic systems thereby redefine standards in automation, promoting designs that harmonize functionality with sustainability. This approach ensures that technologies evolve alongside societal norms, stressing the importance of ecological considerations in technological development.

Future Prospects and Impact

The Bioinspired Robotics Lab at the University of California, San Diego, has achieved significant advancements in developing robotic systems sans electronics, using cutting-edge 3D printing technology. These innovative robots are distinctly designed with six legs and utilize compressed gas for operation, deftly bypassing the necessity of traditional electronic components. This revolutionary approach allows these robots to function effectively in extreme and perilous conditions such as high temperatures, radiation, or rough terrain, which typically incapacitate electronic-based devices. As a result, these robotic systems are ideally suited for continuous operation in environments previously inhospitable to electronic devices, unlocking new potential for their deployment in areas like exploration, disaster response, and industrial inspections. This technology heralds a new era of robotics, presenting invaluable tools for scenarios where traditional electronic devices might falter, thus broadening the horizon for practical applications.