Soft robots present a new frontier in robotics, offering unique capabilities that conventional robots cannot match. These flexible machines have the potential to undertake activities that were once deemed impossible, making them invaluable in various industries and applications. However, controlling soft robots without the need for electronics has been a significant challenge. Yet, a breakthrough by a research team at the University of Freiburg has paved the way for the electronic-free control of soft robots using 3D printed pneumatic logic modules.

Advantages of Soft Robots

The potential of soft robots lies in their ability to tackle unconventional tasks. With their flexible bodies, they can navigate complex environments and interact with delicate objects without causing harm. Additionally, these robots can be deployed in hard-to-reach areas, making them ideal for exploring hazardous environments, such as deep-sea exploration or disaster response scenarios. Unlike metal-based electronically controlled robots, soft robots can withstand exposure to radiation or chemicals, providing a safer alternative for these challenging conditions.

Difficulty in Developing Electronics-Free Controls

The unique nature of soft robots demands innovative control mechanisms that do not rely on electronics, as these components can be incompatible with certain environments. Designing electronic-free control systems is a complex and elusive task due to the lack of suitable alternatives. However, the research team at the University of Freiburg took on this challenge and developed a groundbreaking solution.

Introduction to 3D Printed Pneumatic Logic Modules

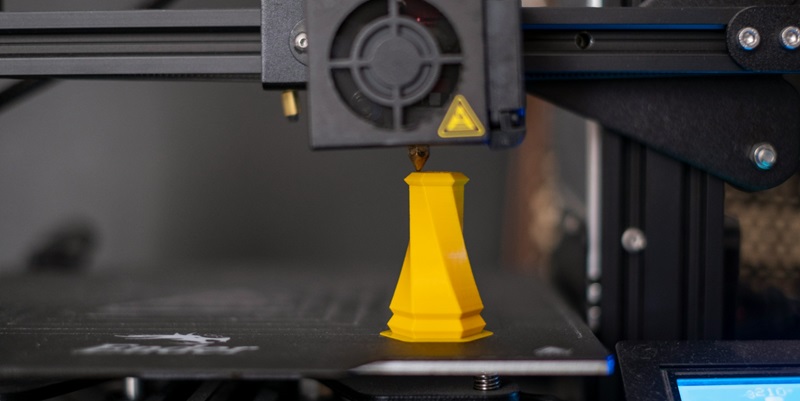

The researchers successfully created 3D-printed pneumatic logic modules that utilize air pressure alone to control the movements of soft robots. By mimicking electrical control, these modules enable logical airflow switching, effectively replicating the functions of electronic circuits. This breakthrough allows for the complete production of flexible, electronic-free soft robots within a 3D printer, using standard filament printing material.

The significance of 3D printed logic modules

What sets these 3D printed pneumatic logic modules apart is their accessibility. The design has been optimized to enable anyone with 3D printing experience to produce these logic modules. By eliminating the need for high-end printing equipment, this technology becomes accessible to a wider audience, opening up possibilities for small-scale production and experimentation. This marks a significant step towards the widespread adoption of electronics-free pneumatic control circuits in soft robotic systems.

Accessibility and Potential Impact of the Technology

The open-source nature of the design further enhances the accessibility and potential impact of this technology. By sharing the design, the research team ensures that individuals and organizations worldwide can benefit from this breakthrough. This democratization of soft robotics enables a collaborative and innovative ecosystem where advancements and improvements can be rapidly achieved.

Contribution and Publication of Research Findings

Led by Dr. Stefan Conrad, Dr. Falk Tauber, Joscha Teichmann, and Professor Dr. Thomas Speck from the Cluster of Excellence, the research team at the University of Freiburg has garnered attention for their groundbreaking work. Their findings have been published in the renowned journal Science Robotics, solidifying the significance and credibility of their research.

Future implications of the research

The implications of this research are vast and promising. With the ability to control soft robots without electronics, these machines can operate in challenging environments without the limitations imposed by traditional electronic control systems. This opens the door for advancements in fields such as space exploration, underwater research, medical assistance, and disaster response, where the need for flexible and adaptable robots is paramount.

The development of 3D printed pneumatic logic modules for electronic-free control of soft robots is a significant milestone in the field of robotics. The research team from the University of Freiburg has achieved not only demonstrates the potential of soft robots, but also addresses the challenges in controlling them without electronics. By providing accessible and easily producible logic modules, this research paves the way for a future where soft robots can undertake activities that were previously unimaginable, revolutionizing industries and applications across the board. With ongoing advancements and collaborations within the soft robotics community, the possibilities for innovation and progress are boundless.